Abrasion resistance treatment method for sliding bearing of centrifugal machine

A sliding bearing and wear-resistant treatment technology, which is used in the fields of chemical industry, food machinery and pharmaceutical industry, can solve the problems of reducing the working efficiency and wear of the centrifuge, and achieve the effect of reducing the friction coefficient, reducing the impurity content of the surface layer and improving the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A wear-resistant treatment method for a sliding bearing for a centrifuge, comprising:

[0017] (1) Heat the inner and outer rings of the sliding bearing to 360°C for 20 minutes, then heat to 900°C for 50 minutes, and then use neon to continuously cool the inner and outer rings of the sliding bearing to room temperature;

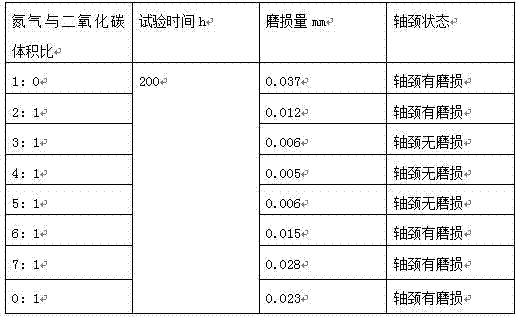

[0018] (2) Place the inner ring and outer ring of the sliding shaft in a nitriding furnace, heat up to 450°C for 10 minutes, pass nitrogen gas, furnace pressure 30 mm water column, keep warm for 12 hours, then raise the temperature to 550°C, and then Introduce carbon dioxide, keep the volume of carbon dioxide and nitrogen in the furnace at 4:1, keep the furnace pressure at 70 mm water column, keep warm for 20 hours, then cool to 150°C and leave the furnace, and then use neon to continuously heat the inner and outer rings of the sliding bearing. Cool down to room temperature;

[0019] (3) After washing once with hot water, dry it naturally, then soak i...

Embodiment 2

[0026] A wear-resistant treatment method for a sliding bearing for a centrifuge, comprising:

[0027] (1) Heat the inner and outer rings of the sliding bearing to 400°C for 20 minutes, then heat to 950°C for 50 minutes, and then use neon gas to continuously cool the inner and outer rings of the sliding bearing to room temperature;

[0028] (2) Place the inner ring and outer ring of the sliding shaft in a nitriding furnace, heat up to 470°C for 10 minutes, pass nitrogen gas, furnace pressure 40 mm water column, keep warm for 14 hours, then raise the temperature to 580°C, and then Introduce carbon dioxide, keep the volume of carbon dioxide and nitrogen in the furnace at 6:1, keep the furnace pressure at 78 mm water column, keep warm for 25 hours, then cool to 150°C and leave the furnace, and then use neon to continuously heat the inner and outer rings of the sliding bearing. Cool down to room temperature;

[0029] (3) After washing with hot water once, let it dry naturally, the...

Embodiment 3

[0036] A wear-resistant treatment method for a sliding bearing for a centrifuge, comprising:

[0037] (1) Heat the inner and outer rings of the sliding bearing to 380°C for 20 minutes, then heat to 930°C for 50 minutes, and then use neon gas to continuously cool the inner and outer rings of the sliding bearing to room temperature;

[0038] (2) Place the inner and outer rings of the sliding shaft in a nitriding furnace, heat up to 460°C and preheat for 10 minutes, pass nitrogen gas, furnace pressure 35 mm water column, keep warm for 13 hours, then raise the temperature to 570°C, and at the same time Introduce carbon dioxide, keep the volume of carbon dioxide and nitrogen in the furnace at 5:1, keep the furnace pressure at 73mm water column, keep warm for 22 hours, then cool to 150°C and leave the furnace, and then use neon to continuously heat the inner ring and outer ring of the sliding bearing. Cool down to room temperature;

[0039] (3) After washing once with hot water, le...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com