A way to improve co 2 Preparation method of iron-based ceramic oxygen-permeable film with oxygen-permeable stability under atmosphere

An oxygen-permeable membrane and stability technology, which is applied in the field of preparation of iron-based ceramic oxygen-permeable membrane, can solve problems such as insufficient stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

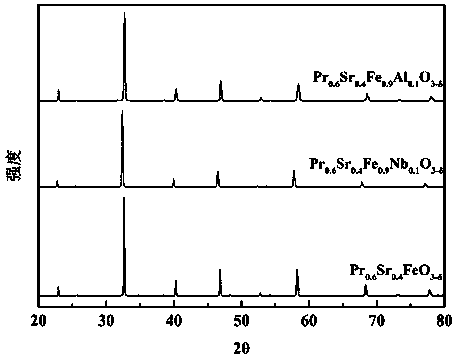

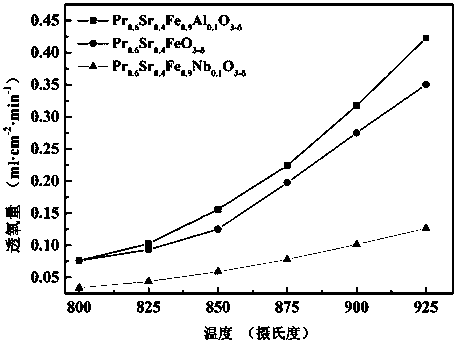

Embodiment 1

[0020] 23.36g Pr(NO 3 ) 3 ·6H 2 O, 7.58g Sr(NO 3 ) 2 , 36.16g Fe(NO 3 ) 3 9H 2 O was dissolved in deionized water, and 52.32g of ethylenediaminetetraacetic acid and 56.43g of citric acid were dissolved in another beaker filled with a certain amount of deionized water. The above two solutions were mixed and heated to 95°C. The pH value of the solution was 7, and heating was continued until a sol-like substance was obtained. Dry the obtained sol at 150°C until it expands into a spongy porous solid, take it out, bake it at 380°C for 10 hours, and then bake it at 950°C for 5 hours to obtain Pr 0.6 Sr 0.4 FeO 3-δ The powder is ground in a mortar for 3 hours to make the particle size uniform, and an appropriate amount of oleic acid is added to the obtained powder, and molded under a pressure of 300MPa. 0.6 Sr 0.4 FeO 3-δ Single-phase mixed conductor oxygen-permeable membrane, that is, iron-based ceramic oxygen-permeable membrane.

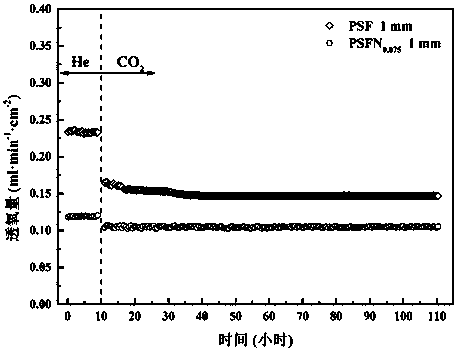

Embodiment 2

[0022] 23.08g Pr(NO 3 ) 3 ·6H 2 O, 7.48g Sr(NO 3 ) 2 , 33.04g Fe(NO 3 ) 3 9H 2 O, 3g of niobium oxalate was dissolved in deionized water, 51.67g of ethylenediaminetetraacetic acid and 55.74g of citric acid were dissolved in another beaker with a certain amount of deionized water, the above two solutions were mixed, and heated to 95 ° C, The pH value of the solution was adjusted to 8 by adding ammonia water dropwise, and the heating was continued until a sol-like substance was obtained, and the obtained sol-like substance was dried at 160° C. for 10 hours. Then calcined at 950°C for 8 hours to obtain Pr 0.6 Sr 0.4 Fe 0.925 Nb 0.075 o 3-δ The powder is ground in a mortar for 3 hours to make the particle size uniform. Add an appropriate amount of oleic acid to the obtained powder, and shape it under a pressure of 300 MPa. The obtained flake body is roasted at 1350 ° C for 8 hours to obtain Pr 0.6 Sr 0.4 Fe 0.925 Nb 0.075 o 3-δ Single-phase mixed conductor oxygen-p...

Embodiment 3

[0024] 22.98g Pr(NO 3 ) 3 ·6H 2 O, 7.45g Sr(NO 3 ) 2 , 32.01g Fe(NO 3 ) 3 9H 2O, 3.98 g of niobium oxalate was dissolved in deionized water, 51.46 g of ethylenediaminetetraacetic acid and 55.51 g of citric acid were dissolved in another beaker with a certain amount of deionized water, the above two solutions were mixed, and heated to 100 ° C , by adding ammonia water dropwise to make the pH value of the solution 8, continue heating until a sol-like substance is obtained, and dry the obtained sol-like substance at 160° C. for 10 hours. Then calcined at 950°C for 8 hours to obtain Pr 0.6 Sr 0.4 Fe 0.9 Nb 0.1 o 3-δ The powder is ground in a mortar for 3 hours to make the particle size uniform. Add an appropriate amount of oleic acid to the obtained powder, and shape it under a pressure of 300 MPa. The obtained flake body is roasted at 1400 ° C for 8 hours to obtain Pr 0.6 Sr 0.4 Fe 0.9 Nb 0.1 o 3-δ Single-phase mixed conductor oxygen-permeable membrane, that is, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com