A kind of polyurethane foam used for refrigerator door overturning beam and its application

A refrigerator door body and overturning beam technology, applied in the field of foamed polyurethane, can solve the problems of high viscosity of polyurethane raw materials, failure to achieve thermal insulation performance, poor filling, etc., achieve high thermal insulation performance, increase surface temperature, and reduce heating frequency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

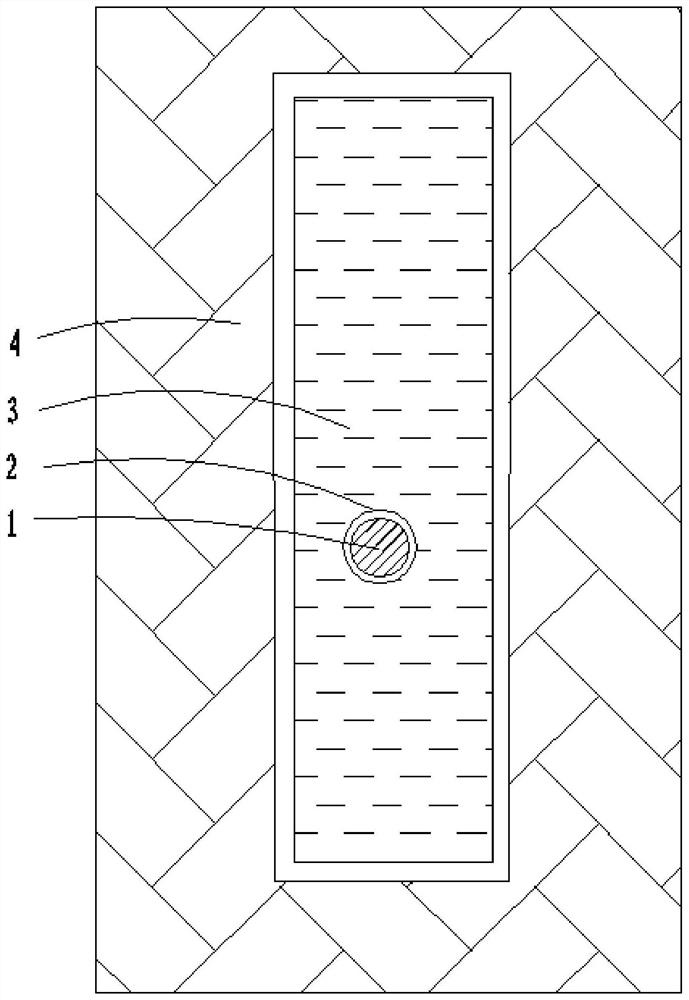

Image

Examples

Embodiment 1

[0034] In this embodiment, the high-fluidity foamed polyurethane used for the overturning beam of the refrigerator door body has the following raw materials in parts by mass:

[0035] Combined polyether 100 parts,

[0036] 18 parts of foaming agent cyclopentane,

[0037] 161 parts of isocyanate;

[0038] The combined polyether includes polyether polyol, catalyst, water and foam stabilizer, etc. The viscosity is 2500-3000mPa·s under the test condition of 25°C. The lower viscosity is 200-300mPa·s. The combined polyether is provided by BASF Polyurethane Specialty Products (China) Co., Ltd., and the brand name is CH2031 / 151.

[0039] The isocyanate is polymethylene polyphenyl isocyanate, the isocyanate content is 30-32%, and the viscosity at room temperature is 300-450mPa·s;

[0040] In this embodiment, the door body of the refrigerator turns over the beam, and the heat-insulating rigid polyurethane foam in the turning beam is the above-mentioned foamed polyurethane material, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com