Ultra-high molecular polyethylene/poly (4-methyl-1-amylene) blended microporous membrane prepared with thermally induced phase separation method and preparation method thereof

A heat-induced phase separation method and ultra-high molecular technology, which is applied in the field of ultra-high molecular polyethylene/poly blend microporous membrane and its preparation, can solve the problem that the heat resistance, liquid absorption and safety of traditional diaphragms cannot meet the requirements And other problems, to achieve the effect of high heat resistance, high melting temperature, high tensile modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

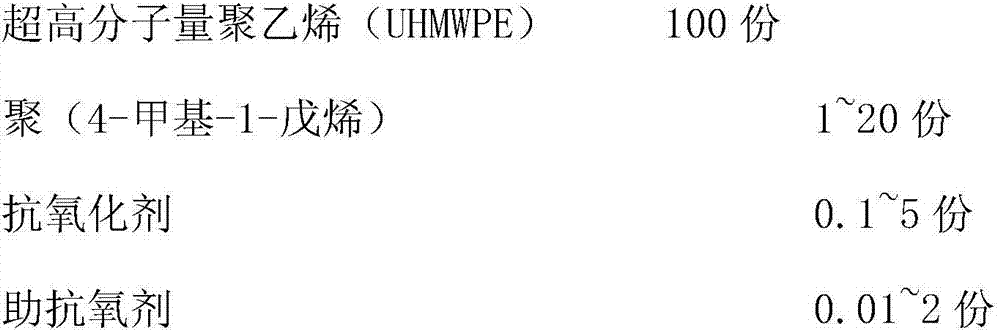

Method used

Image

Examples

Embodiment 1

[0021] According to 5 parts of TPX (commercially available, MX002) and 1 part of antioxidant (β-(3,5-di-tert-butyl-4-hydroxyphenyl) isooctyl propionate), 0.05 part of auxiliary antioxidant ( Pentaerythritol distearyl diphosphite) blend. Put the above mixed TPX and UHMWPE powder into the extruder at a ratio of 5:100, plasticize with paraffin oil, and blend evenly.

[0022] The melt formed by the twin-screw extruder passes through the die head and the quenching roll to form an oil film, and the oil film is subjected to biaxial stretching, extraction, and heat setting to obtain ultra-high molecular weight polyethylene / poly(4-methyl-1-pentene) The microporous membrane of the present invention can be obtained by blending the microporous membrane. The performance test results are shown in Table 1.

Embodiment 2

[0026] According to 5 parts of TPX (commercially available, MX002) and 1 part of antioxidant (β-(3,5-di-tert-butyl-4-hydroxyphenyl) isooctyl propionate), 0.05 part of auxiliary antioxidant ( Pentaerythritol distearyl diphosphite) blend. Add the above mixed TPX and UHMWPE powder into the extruder at a ratio of 10:100, plasticize with paraffin oil, and blend evenly.

[0027] The melt formed by the twin-screw extruder passes through the die head and the quenching roll to form an oil film, and the oil film is subjected to biaxial stretching, extraction, and heat setting to obtain ultra-high molecular weight polyethylene / poly(4-methyl-1-pentene) The microporous membrane of the present invention can be obtained by blending the microporous membrane. The performance test results are shown in Table 1.

Embodiment 3

[0029] According to 5 parts of TPX (commercially available, MX002) and 1 part of antioxidant (β-(3,5-di-tert-butyl-4-hydroxyphenyl) isooctyl propionate), 0.05 part of auxiliary antioxidant ( Pentaerythritol distearyl diphosphite) blend. Put the above mixed TPX and UHMWPE powder into the extruder at a ratio of 15:100, plasticize with paraffin oil, and blend evenly.

[0030] The melt formed by the twin-screw extruder passes through the die head and the quenching roll to form an oil film, and the oil film is subjected to biaxial stretching, extraction, and heat setting to obtain ultra-high molecular weight polyethylene / poly(4-methyl-1-pentene) The microporous membrane of the present invention can be obtained by blending the microporous membrane. The performance test results are shown in Table 1.

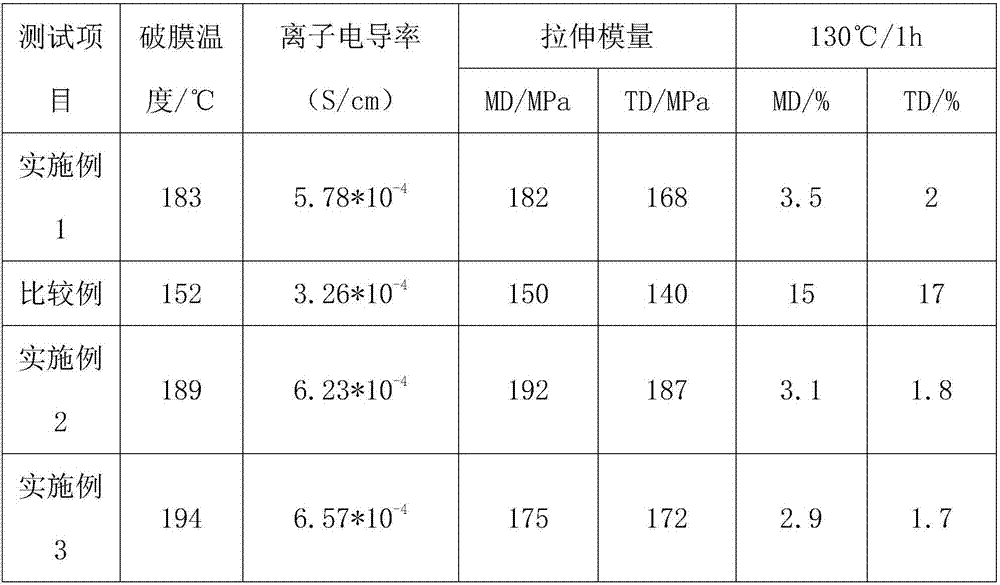

[0031] Table 1

[0032]

[0033] It can be seen from Table 1 that the ultra-high molecular weight polyethylene / poly(4-methyl-1-pentene) blended microporous membrane added with pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com