Process for preparing humic acid coproduced energy gas and biological carbon by hydrothermal carbonization of organic wastes

A technology of hydrothermal carbonization and organic waste, applied in waste fuel, petroleum industry, special form of dry distillation, etc., can solve the problems of prolonging anaerobic digestion cycle, complex organic waste composition, reducing anaerobic digestion production capacity, etc., to improve the quality of agricultural products , the effect of high yield of renewable resources and low yield of waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

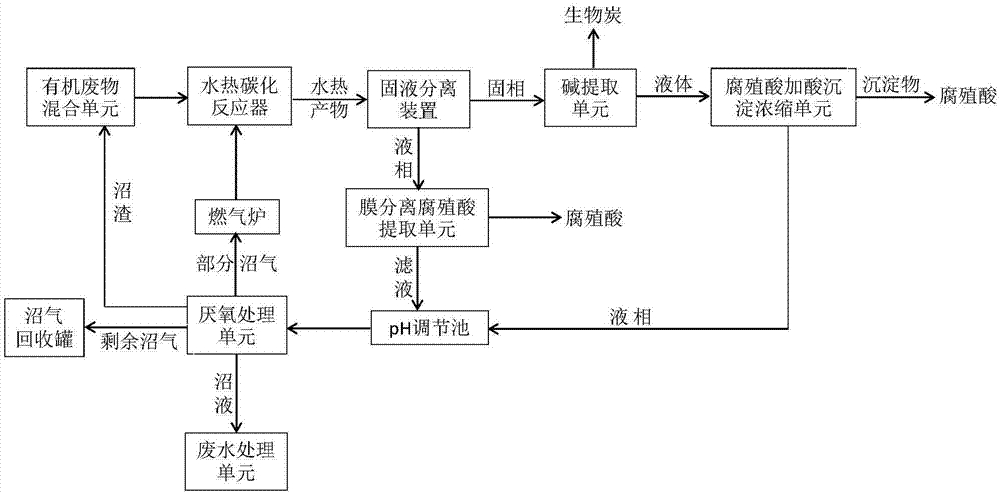

[0020] A process for producing humic acid and co-producing energy gas and biochar by hydrothermal carbonization of organic waste. The devices used in the process include an organic waste mixing unit, a hydrothermal carbonization reactor, a solid-liquid separation device, an alkali extraction unit, and a humic acid extraction unit. Acid plus acid precipitation concentration unit, membrane separation humic acid extraction unit, pH adjustment tank, anaerobic treatment unit, wastewater treatment unit, gas furnace, biogas recovery tank;

[0021] The organic waste mixing unit, hydrothermal carbonization reactor, solid-liquid separation device, alkali extraction unit and humic acid plus acid precipitation concentration unit are connected in sequence; organic waste with a particle size of 30 mesh and water are mixed in the organic waste with a mass ratio of 8:2 Mix evenly in the mixing unit, and then send it to the hydrothermal carbonization reactor for hydrothermal carbonization react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com