Multi-stage shaking type bioreactor

A bioreactor and shaking technology, which is applied in the direction of bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, biochemical instrument, etc., can solve the difficulty in providing wave-making ability and turbulence degree of the bottom layer of the culture solution Small size, low gas mass transfer efficiency, etc., to achieve high gas mass transfer efficiency, large turbulence, and improved scalability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

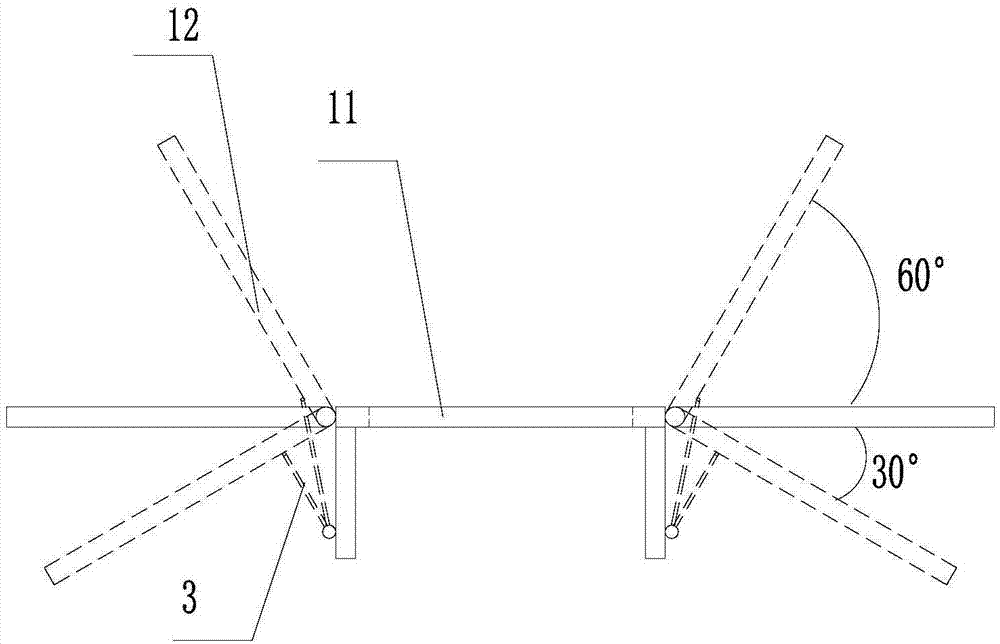

[0029] Embodiment 1 A multi-stage rocking bioreactor according to the present invention includes a multi-stage rocking platform 1 for supporting a disposable bioreactor bag, and a divider for increasing the turbulent degree of the culture solution at the bottom of the fixed plate support area. A stepped annular disturbance 2, a driving device for providing a driving force, and a controller for the driving device, the multi-stage rocking platform 1 is fixedly connected to the stepped annular disturbance 2, and the driving device is set At the multi-stage rocking platform 1, and the control terminal of the driving device is electrically connected to the corresponding pin of the controller;

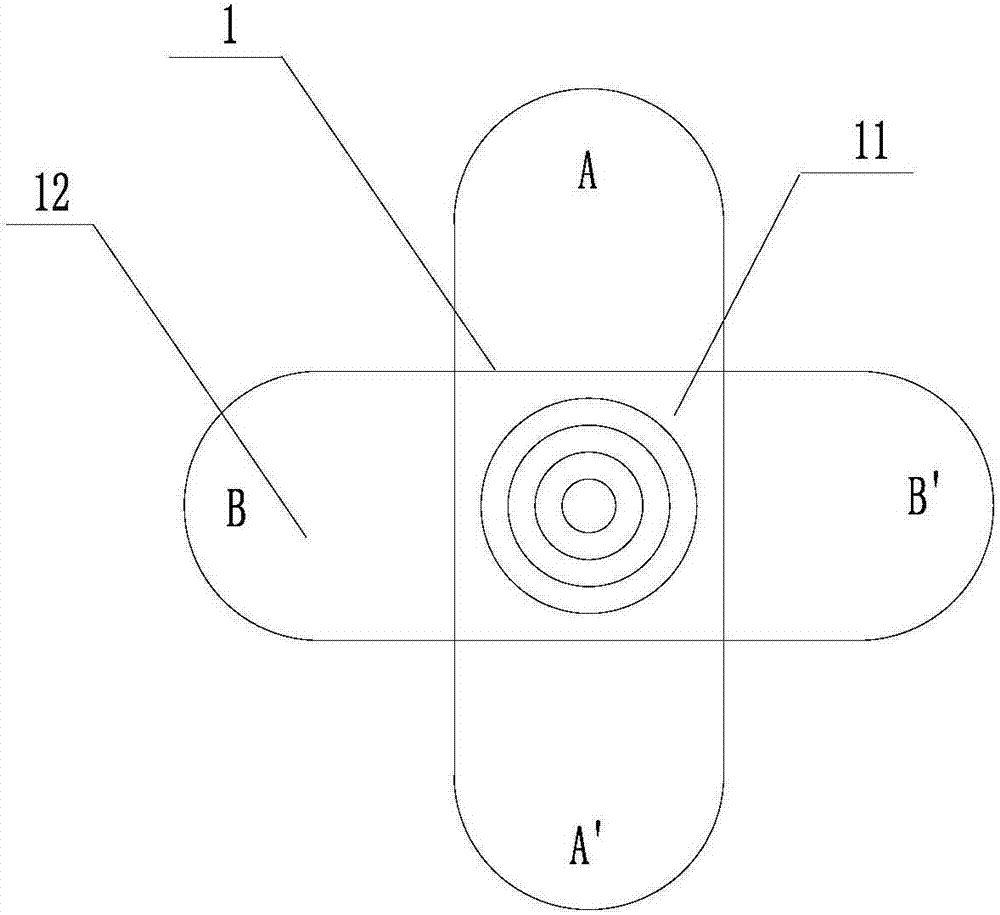

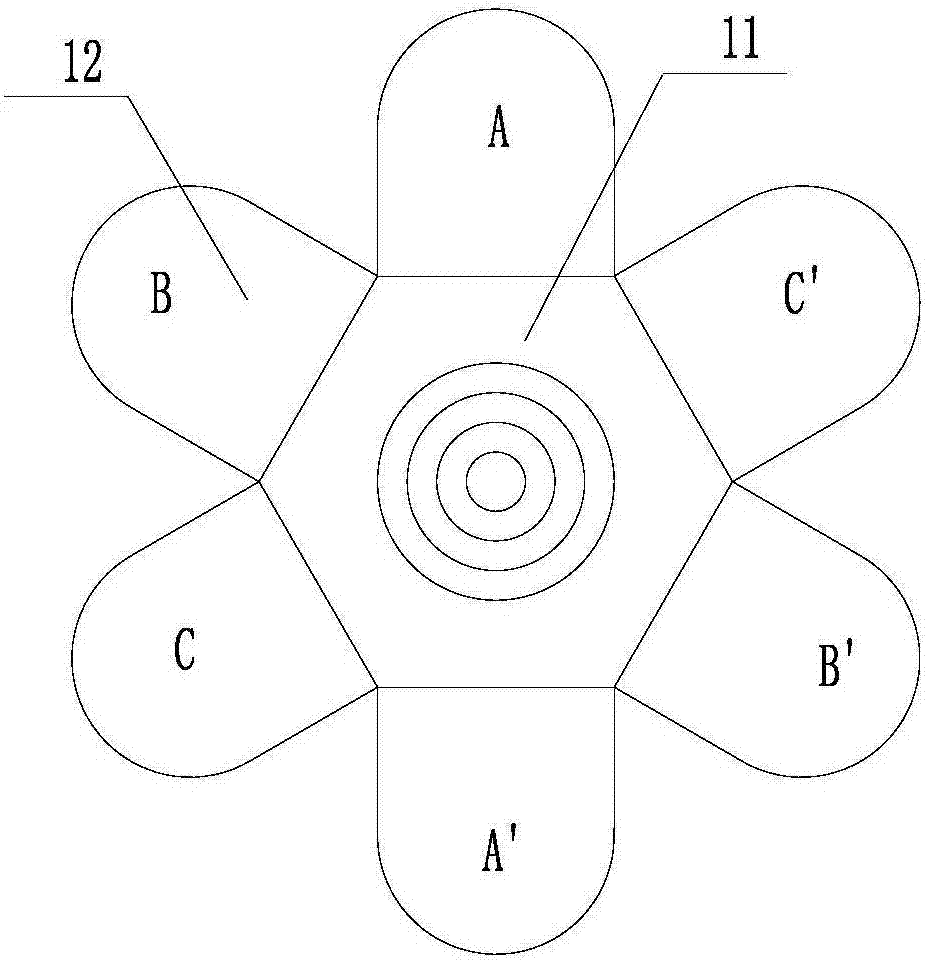

[0030] The multi-stage rocking platform 1 comprises a polygonal flat plate 11 and a shaking flat plate 12, the number of sides of the polygonal flat plate 11 is an even number, and the center of the polygonal flat plate 11 is provided with a through hole for the stepwise annular disturbance t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com