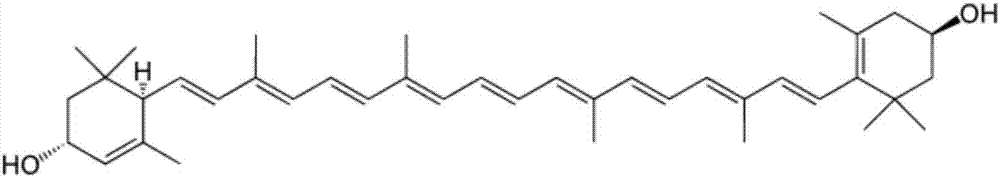

Microcapsules comprising lutein or lutein ester

A technology of lutein esters and microcapsules, which is applied in the field of products containing such microcapsules, and can solve the problems of expensive preparation methods and time-consuming preparations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

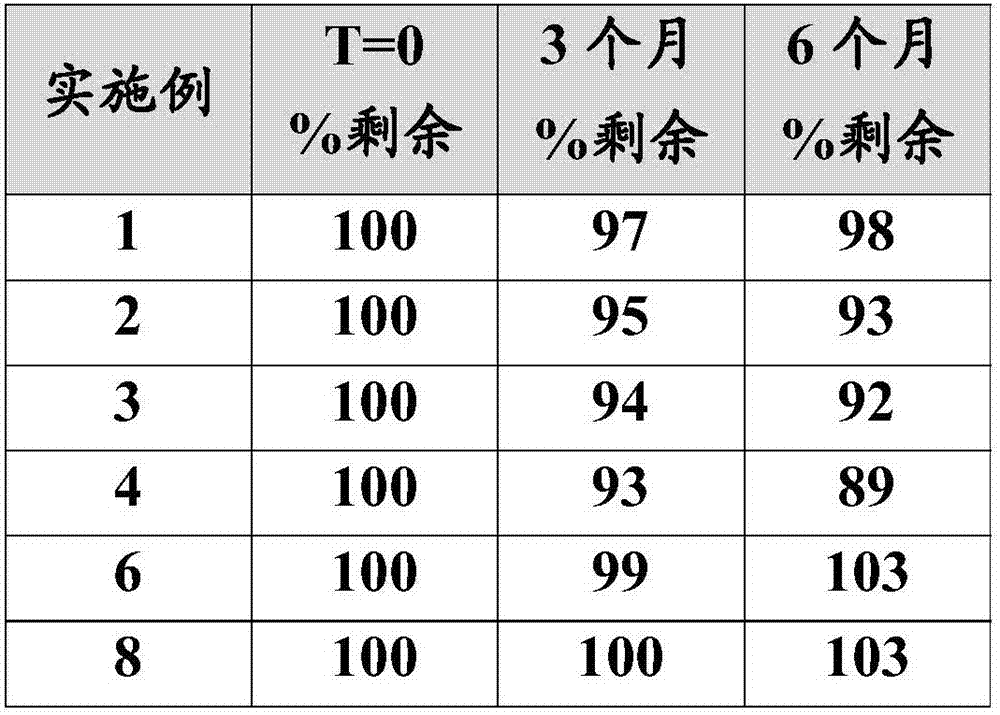

Embodiment 1

[0062] During stirring, 514 g of natural gum arabic, 171 g of sucrose and 18 g of sodium ascorbate were dissolved in 600 g of water at 65°C. During stirring, 180 g of lutein ester concentrate and 17.2 g of mixed tocopherols (70% concentrate) were added, and then homogenized until the lutein ester droplets had an average particle size D of less than 1.0 μm [4;3 ]. Water was used to adjust the viscosity and the dispersion was sprayed into native cornstarch containing silica as flow agent. The formed granules are dried in air at 40-150°C until the moisture content in the powder is below 5%.

[0063] The dry powder obtained had a lutein ester content of 11.3%, which corresponds to 6.08% free lutein as determined by UV / Vis spectroscopy.

Embodiment 2

[0065] In vessel A, 1541 g of natural gum arabic, 382 g of sucrose and 54 g of sodium ascorbate were dissolved in 1800 g of water at 65° C. during stirring. In vessel B, 540 g of lutein ester concentrate were melted together with 137 g of MCT oil and 48.2 g of mixed tocopherols (70% concentrate) at 60-90°C. During stirring, the oil phase from vessel B was added to the water phase in vessel A and then homogenized until the lutein ester droplets had an average particle size D [4; 3] of less than 1.0 μm. Water was used to adjust the viscosity and the dispersion was sprayed into native cornstarch containing silica as flow agent. The formed granules are dried in air at 40-150°C until the moisture content in the powder is below 5%.

[0066] The dry powder obtained had a lutein ester content of 10.9%, which corresponds to 5.87% free lutein as determined by UV / Vis spectroscopy.

Embodiment 3

[0068] In vessel A, 1541 g of natural gum arabic, 382 g of sucrose and 54 g of sodium ascorbate were dissolved in 1800 g of water at 65° C. during stirring. In vessel B, 540 g of lutein esters concentrate were melted together with 137 g of hydrogenated palm oil and 48.2 g of mixed tocopherols (70% concentrate) at 60-90°C. During stirring, the oil phase from vessel B was added to the water phase in vessel A and then homogenized until the lutein ester droplets had an average particle size D [4; 3] of less than 1.0 μm. Water was used to adjust the viscosity and the dispersion was sprayed into native cornstarch containing silica as flow agent. The formed granules are dried in air at 40-150°C until the moisture content in the powder is below 5%.

[0069] The dry powder obtained had a lutein ester content of 12.2%, which corresponds to 6.57% free lutein as determined by UV / Vis spectroscopy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com