Asphalt waterproofing paint for roads and bridges and preparation method thereof

A kind of asphalt waterproof coating, road and bridge technology, applied in the direction of asphalt coating, coating, conjugated diene coating, etc., can solve the problems of poor storage stability, poor low temperature weather resistance, long drying time, etc., and achieve high elongation at break , high tensile strength, and the effect of simplifying the construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

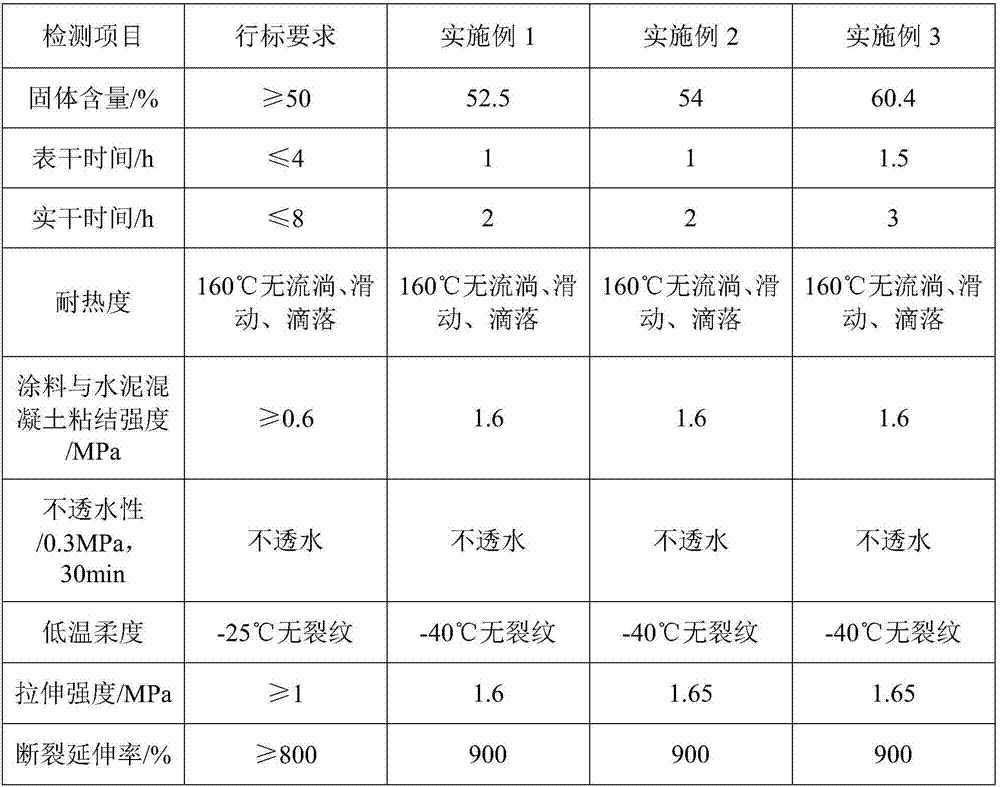

Examples

preparation example Construction

[0031] According to the second aspect of the present invention, the present invention provides a kind of preparation method of above-mentioned asphalt waterproof coating for road and bridge, and this preparation method comprises:

[0032] 1) melting the asphalt to obtain molten asphalt;

[0033] 2) uniformly mixing the cationic emulsifier with part of the water, and then uniformly mixing with the polymer latex to obtain a soap solution;

[0034] 3) processing the soap liquid and the molten asphalt through a colloid mill to obtain a modified emulsion asphalt;

[0035] 4) uniformly mixing the ultrafine wollastonite powder, thickener and remaining water to obtain a mixed slurry;

[0036] 5) uniformly mixing the modified emulsion asphalt with the mixed slurry to obtain the asphalt waterproof coating for road and bridge.

[0037] Preferably, in step 3), the soap liquid and the molten asphalt are passed into the colloid mill for treatment according to the volume ratio of 5:4 to 5:...

specific Embodiment approach

[0038] According to a kind of preferred embodiment, the preparation method of bituminous waterproof coating for road and bridge of the present invention comprises:

[0039] 1) Raise the temperature of asphalt to 130-140°C to obtain molten asphalt;

[0040] 2) Warm up water accounting for 50-86% by weight of the total amount to 55-60°C, add cationic emulsifier, stir for 0.5-2 hours, then add polymer latex, and stir at high speed for 0.5-2 hours to prepare soap liquid;

[0041] 3) The soap liquid and the molten asphalt are processed through a colloid mill according to the volume ratio of 5:4 to 5:7 to obtain a modified emulsified asphalt;

[0042] 4) Mix the ultrafine wollastonite powder, thickener and remaining water, and stir at high speed for 2-3 hours to obtain a mixed slurry;

[0043] 5) Mix the mixed slurry with the modified emulsified asphalt, and stir at a medium speed for 1-2 hours to obtain the asphalt waterproof coating for road and bridge.

[0044] As mentioned abo...

Embodiment 1

[0053] This implementation is used to illustrate the asphalt waterproof coating for road and bridge of the present invention and its preparation method.

[0054] Raw material composition: 30 parts of asphalt, 0.2 parts of cationic emulsifier, 4 parts of polymer latex, 1 part of thickener, 2 parts of superfine wollastonite powder, and 32 parts of water.

[0055] The preparation process is as follows:

[0056] 1) Add asphalt in the reaction vessel 1, and heat up to 135°C;

[0057] 2) Add 20 parts of water into the reaction vessel 2, heat up to 55°C; add cationic emulsifier in the water, stir for 1 hour until dissolved, then add polymer latex, stir at high speed for 1 hour to form soap liquid;

[0058] 3) The soap liquid in the reaction vessel 2 and the molten asphalt in the reaction vessel 1 are sheared and emulsified through a colloid mill according to the volume ratio of 5:4 to obtain a modified emulsified asphalt, cooled to room temperature, and transferred to The reaction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com