Refueling method and system

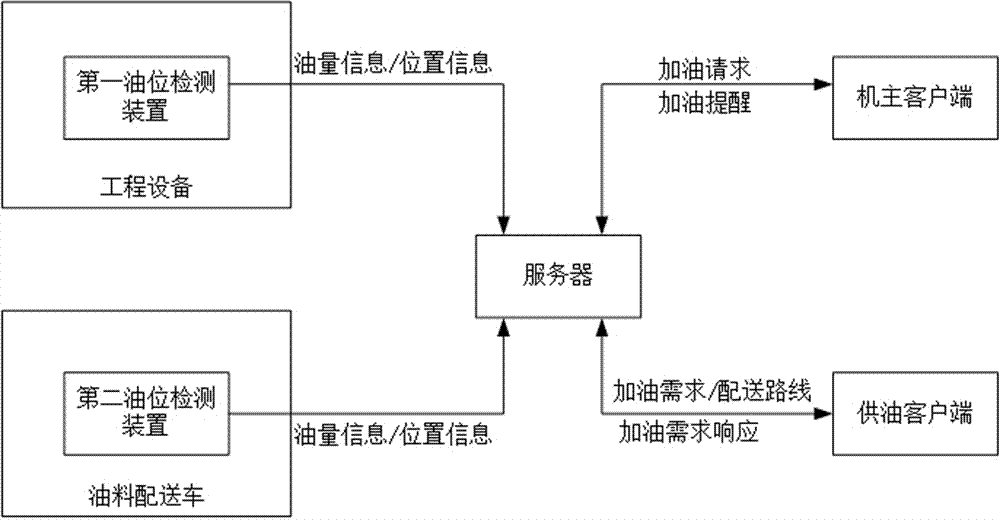

A fueling system and fuel technology, applied in transmission systems, forecasting, resources, etc., can solve the problems of construction machinery and equipment affecting the progress of the project, the timeliness and convenience of the fueler and the fuel supplier, and the existence of safety risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The first oil level detection device is installed on the engineering equipment, and the first oil level detection device is directly connected to the liquid level sensor of the engineering equipment. At the same time, the first oil level detection device is also integrated with a GPS positioning module and a 3G / 4G communication module; if the project If the liquid level sensor on the equipment is unavailable or cannot be connected, the first oil level detection device also includes a separate sensor for measuring the oil quantity in the oil tank of the engineering equipment, which can be measured indirectly by ultrasonic measurement or other methods remaining fuel in the tank. The first oil level detection device detects the oil volume of the oil tank of the engineering equipment with the first detection frequency (for example, once every 10 minutes) through the liquid level sensor of the engineering equipment or a separate sensor, and at the same time detects the curren...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com