Metal oxide /MXene two-dimensional nanometer compound, preparation method and application thereof

A two-dimensional nanotechnology, oxide technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of metal oxides not well combined, poor water solubility, etc., to improve the electrochemical Good performance, good conductivity, and the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

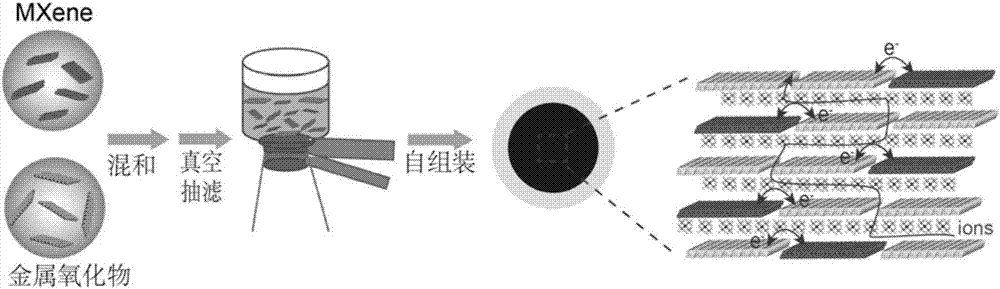

[0034] As one of the preferred embodiments, the preparation method specifically includes:

[0035] The metal oxide nanosheet solution and the MXene two-dimensional nanosheet solution are ultrasonically mixed to obtain a mixed solution, and the mixed solution is vacuum filtered to obtain a metal oxide / MXene two-dimensional nanocomposite.

[0036] Preferably, the mass ratio of the metal oxide nanosheets to the MXene two-dimensional nanosheets is 1:1˜9:1.

[0037] Further, the pressure of the vacuum filtration is about 5-20Mpa.

[0038] Further, the solvent includes alcohol solvents such as ultrapure water and ethanol, but is not limited thereto.

[0039] As one of the preferred embodiments, the lateral size of the metal oxide nanosheets is 1-2 μm.

[0040] Preferably, the metal oxide nanosheets include MnO 2 , ZnO, V 2 o 5 , Fe 3 o 4 etc., but not limited to this.

[0041] As one of the preferred embodiments, the lateral size of the MXene two-dimensional nanosheets is 1-...

Embodiment 1

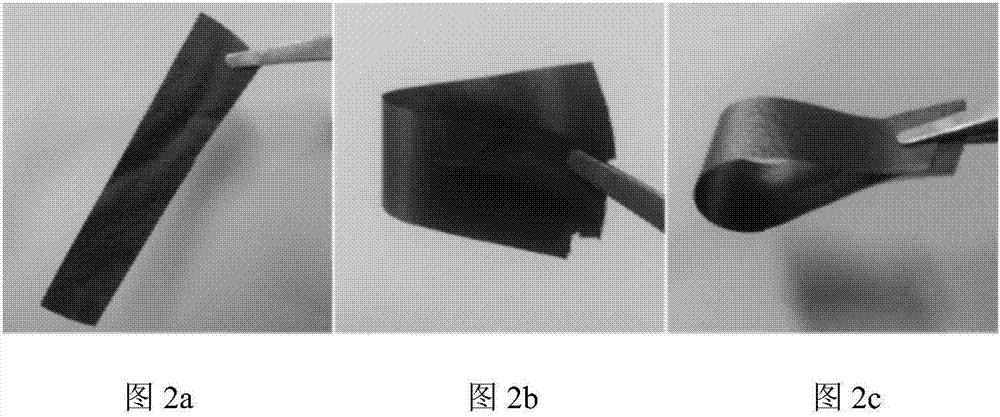

[0053] The metal oxide and MXene nanosheet solution were ultrasonically mixed according to the mass ratio of 9:1, then vacuum filtered, and then the obtained composite electrode was transferred to the stainless steel mesh substrate by pressing the sheet for electrochemical analysis. test. The prepared flexible composite electrodes were tested in a three-electrode manner.

Embodiment 2

[0055] The metal oxide and MXene nanosheet solution were ultrasonically mixed according to the mass ratio of 4:1, then vacuum filtered, and then the obtained composite electrode was transferred to the stainless steel mesh substrate by pressing the sheet for electrochemical analysis. test. The prepared flexible composite electrode is tested in a three-electrode manner, and the CV and GCD curves of the three-electrode test can be found in Figure 4a with Figure 4b . This flexible composite electrode is further assembled into a flexible capacitor, see Figure 8a shown. Carry out flexible characterization to the flexible capacitor of this embodiment, its performance parameter sees Figure 8b shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com