Silicon-based organic light emitting device of higher performance and manufacturing method thereof

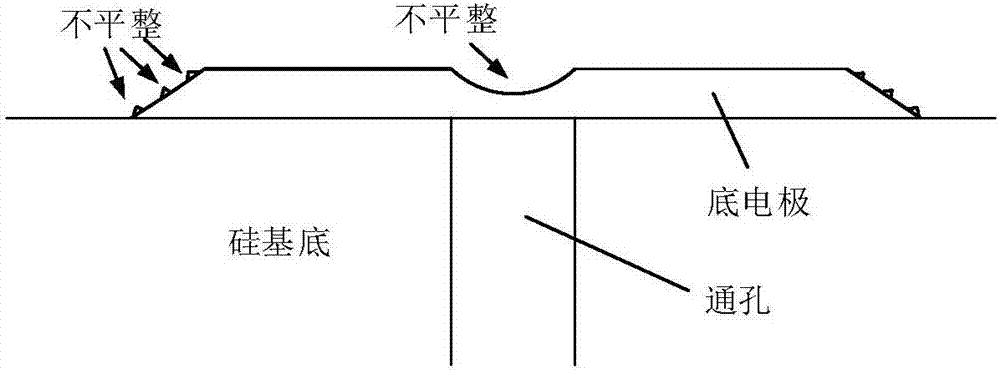

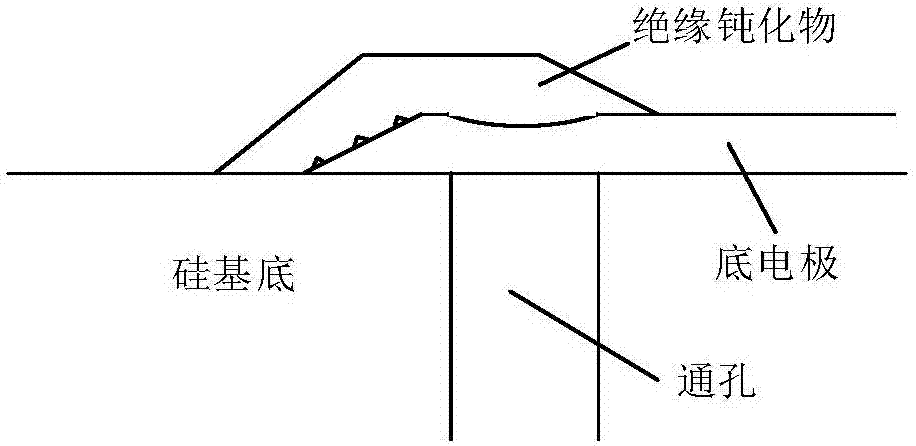

A technology of organic light-emitting devices and organic light-emitting layers, which is applied in the manufacture of semiconductor/solid-state devices, electric solid-state devices, semiconductor devices, etc., can solve problems such as affecting luminous efficiency, unevenness, unevenness and wrinkles on the surface or side of the bottom electrode, and achieves Improve luminous efficiency and improve the effect of flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

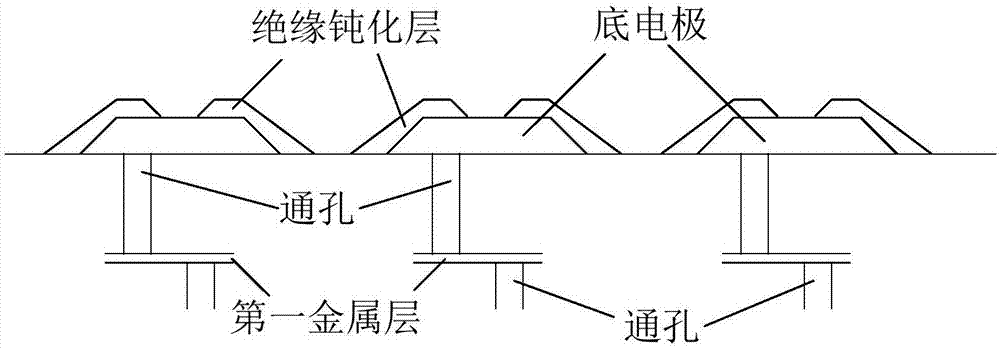

[0040] Such as image 3 As shown, the silicon-based organic light-emitting device described in the present invention includes a silicon substrate 10, a metal-oxide semiconductor field-effect transistor 11, a first metal layer 12, a through hole 13, a bottom electrode 14, an organic light-emitting layer 15, and a top electrode 16 , a thin film encapsulation layer 17 and a common electrode 18, the metal-oxide semiconductor field effect transistor 11 is located in the silicon substrate 10, the bottom electrode 14 protrudes from the silicon substrate surface 10, and the edge of the bottom electrode 14 is formed by The insulating passivation 20 covers and the uncoated area of the bottom electrode 14 is a light emitting area, the common electrode 18 selectively covers the insulating passivation 20, and the through hole 13 connects the first metal layer 12 and The bottom electrode 14 .

[0041] Further, as Figure 4 As shown, the organic light-emitting layer 15 covers the bottom ...

no. 2 example

[0047] In this embodiment, the silicon-based organic light-emitting device is basically the same as the first embodiment, in particular, the top view of the bottom electrode 14 is shown in Figure 7(a)-(c), the through hole 13 is arranged at the edge or four corners of the bottom electrode and protrudes from the light-emitting area 40 , the protruding part is 91 , and the bottom electrode is covered with insulating passivation 20 . Further, the bottom electrode portion on the through hole 13 is covered by the insulating passivation 20 . Figure 7(a) is a top view of the through hole 13 arranged at the edge of the bottom electrode, Figure 7(b) is a top view of the through hole 13 arranged at the corner of the bottom electrode, and Figure 7(c) is another through hole 13 is the top view of the corner position of the bottom electrode.

[0048] further, Figure 8 A pixel array composed of several bottom electrodes 14 is illustrated, and in this array, the positions where the throug...

no. 3 example

[0054] In this embodiment, the silicon-based organic light-emitting device is basically the same as the first embodiment, in particular, a second metal layer is provided between the bottom electrode and the first metal layer, and the through hole and the first metal layer are arranged staggered at the same level, such as Figure 11 shown.

[0055] Further, the second metal layer is configured as a ground or a power supply, and the material of the second metal layer includes Al, Ag, Ti, W, Cu, Ta simple substance or one of oxides, nitrides, and silicides. One or a mixture of the above materials in any proportion.

[0056] Further, the thickness of the second metal layer is 50nm-700nm.

[0057] The present invention also provides a method for manufacturing the silicon-based organic light-emitting device, comprising the following steps: making a bottom electrode on a silicon-based substrate; using a mask to directly make an insulating passivation or first making an insulating p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com