Self-propelled electric green leafy vegetable harvesting machine

A self-propelled technology for green leafy vegetables, applied in the direction of harvesters, cutters, agricultural machinery and implements, etc., can solve the problem of waste gas emissions affecting human health and crop quality, and cannot automatically adjust the position of the header, and cannot automatically adjust the height of the header And other problems, to achieve the effect of convenient operation speed, low noise, easy to popularize and apply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only part of the embodiments of the present invention, not all of them. In the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

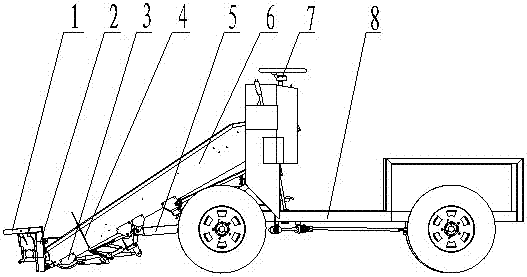

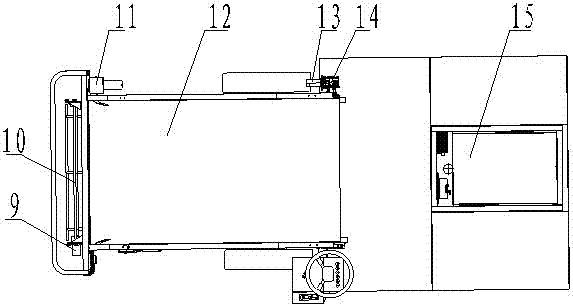

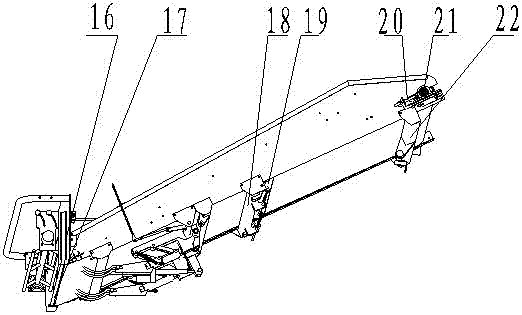

[0037] see figure 1 and figure 2 , The present invention provides a self-propelled electric green leafy vegetable harvester, which is mainly composed of a vehicle frame 8, a driving device, a header mechanism, a walking chassis, a hydraulic lifting device, a ground profiling mechanism and a driving console 7. A safety guard 1 is housed outside the band saw cover 2 . figure 1 and figure 2 The components s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com