Casting wax mold exterior coating and method for manufacturing mold shell through coating

A technology for external coatings and casting wax molds, which is applied in the direction of casting molding equipment, casting molds, and casting mold components. Scientific norms to ensure the effect of precise performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

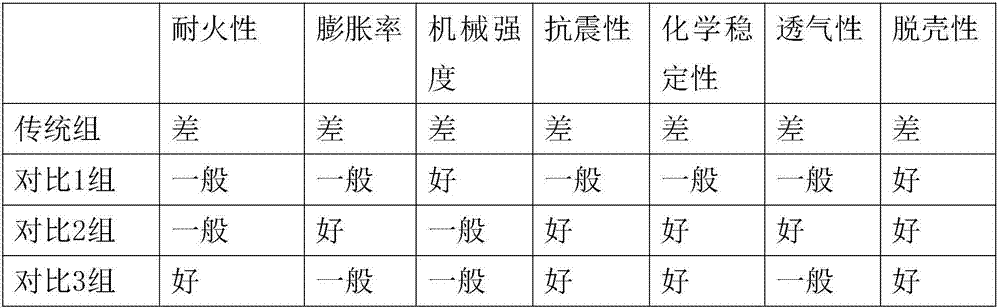

Embodiment 1

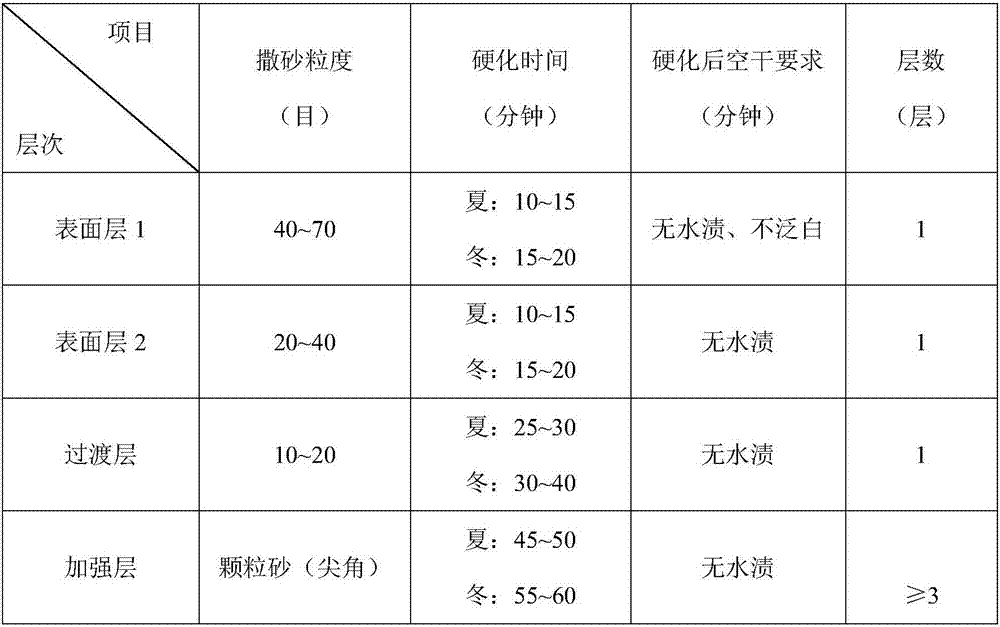

[0024] An external coating for casting wax patterns, characterized in that it consists of a surface layer 1, a surface layer 2, a transition layer and a strengthening layer;

[0025] The first surface layer includes: 32.5% of primary water glass, 1.4% of quartz powder, and the balance is well mud powder;

[0026] The second surface layer comprises: 32.5% of primary water glass, 1.3% of quartz powder, and the balance is well mud powder;

[0027] The transition layer comprises: 37.5% of secondary water glass, 31.75% of quartz powder, and the balance is well mud powder;

[0028] The reinforcing layer comprises: 37.5% of secondary water glass, 24.5% of quartz powder, and the balance is well mud powder;

[0029] The first-grade water glass comprises the following components: 22% silicon dioxide, 7.1% sodium oxide, and the balance is silica sand;

[0030] The secondary water glass comprises the following components: 26% silicon dioxide, 8.5% sodium oxide, and the balance being sil...

Embodiment 2

[0040] An exterior coating for casting wax patterns, comprising a surface layer 1, a surface layer 2, a transition layer and a strengthening layer;

[0041] The first surface layer includes: 32% of primary water glass, 1.3% of quartz powder, and the balance is well mud powder;

[0042] The second surface layer comprises: 32% of primary water glass, 1.2% of quartz powder, and the balance is well mud powder;

[0043] The transition layer comprises: 37% of secondary water glass, 31.5% of quartz powder, and the balance is well mud powder;

[0044] The reinforcing layer comprises: 37% of secondary water glass, 24% of quartz powder, and the balance is well mud powder;

[0045] The first-grade water glass comprises the following components: 21% silicon dioxide, 6.7% sodium oxide, and the balance being silica sand;

[0046] Described secondary water glass comprises the following components: 24% of silicon dioxide, 8% of sodium oxide, and the balance is silica sand;

[0047] A metho...

Embodiment 3

[0056] An exterior coating for casting wax patterns, comprising a surface layer 1, a surface layer 2, a transition layer and a strengthening layer;

[0057] The first surface layer includes: 33% of primary water glass, 1.5% of quartz powder, and the balance is well mud powder;

[0058] The second surface layer comprises: 33% of primary water glass, 1.4% of quartz powder, and the balance is well mud powder;

[0059] The transition layer comprises: 38% of secondary water glass, 32% of quartz powder, and the balance is well mud powder;

[0060] The reinforcing layer comprises: 38% of secondary water glass, 25% of quartz powder, and the balance is well mud powder;

[0061] The first-grade water glass comprises the following components: 23% silicon dioxide, 7.5% sodium oxide, and the balance being silica sand;

[0062] The secondary water glass comprises the following components: 28% silicon dioxide, 9% sodium oxide, and the balance being silica sand;

[0063] A method for manuf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com