Method and equipment for treating swine wastewater

A waste water and equipment technology, which is applied in the direction of sludge treatment, filtration treatment, water/sewage treatment, etc., can solve the problems affecting the health and normal life of residents, high waste water stock, large floor area, etc., to achieve excellent water quality, The effect of reducing handling pressure and occupying a small area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

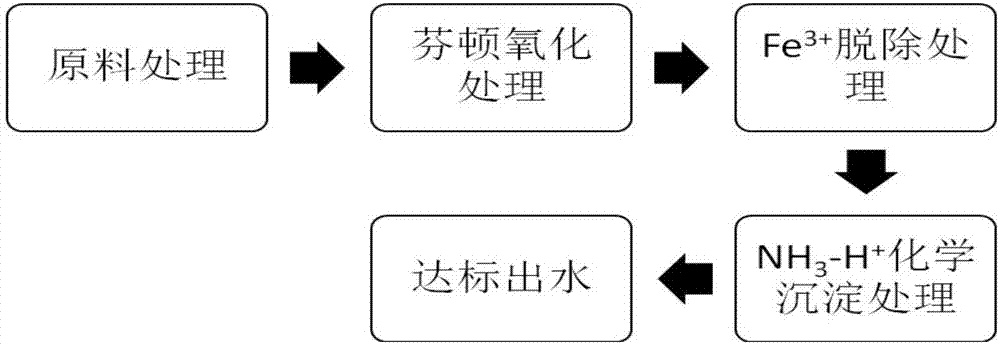

[0043] Such as figure 1 In the shown treatment process, the pig raising wastewater is treated by sand filtration, and the solid particles of the pig raising wastewater are filtered.

[0044] The water quality of pig raising wastewater after filtration is shown in the table:

[0045] Table 1-1 Water Quality Analysis of Pig Raising Wastewater

[0046]

[0047] Regulate described waste water pH value with sulfuric acid to be 5, drop into FeSO2 by the amount of 50mmol / L subsequently 4 , according to 1 / 3.5 of the volume of wastewater to be treated into 30% mass concentration of H 2 o 2 Solution, reaction time 24h. The comparison of wastewater quality after treatment according to the stated conditions and before treatment is shown in the following table:

[0048] Table 1-2 Comparison of water quality of water samples before and after Fenton oxidation treatment under suitable conditions

[0049]

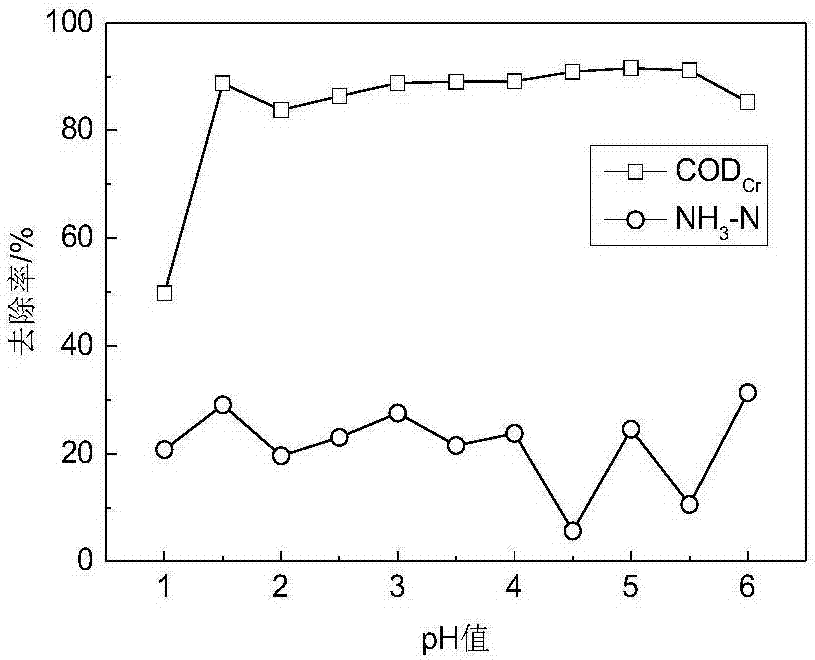

[0050] Fenton oxidation treatment COD under this condition Cr The removal ra...

Embodiment 2

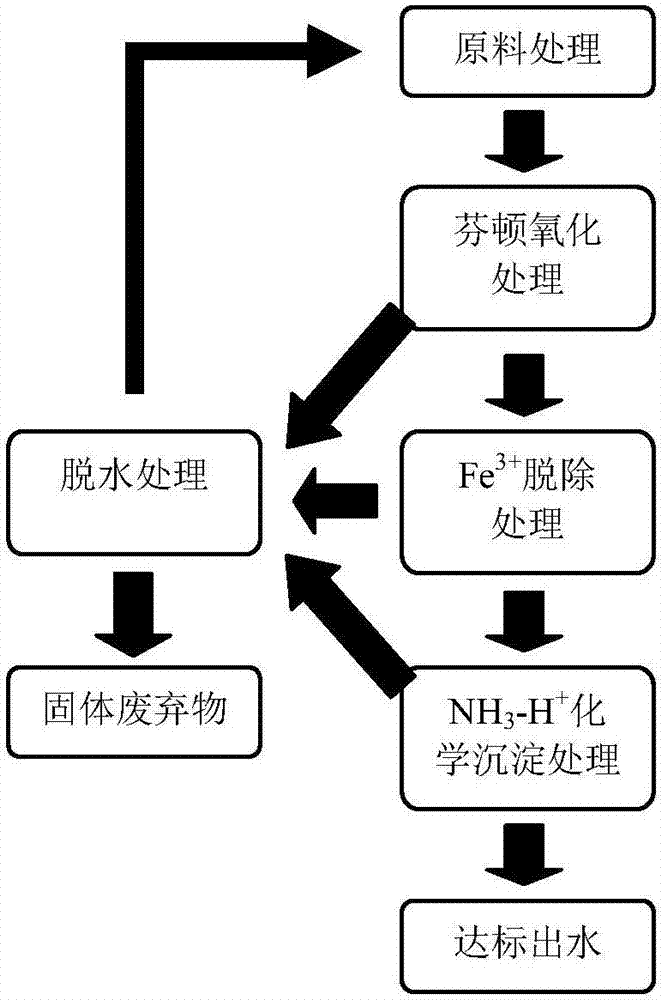

[0058] Such as figure 2 In the shown treatment process, the raw material treatment of the pig raising wastewater is carried out by means of filter bed filtration, and the solid particles of the pig raising wastewater are filtered.

[0059] The water quality of pig raising wastewater after filtration is shown in the table:

[0060] Table 2-1 Water Quality Analysis of Pig Raising Wastewater

[0061]

[0062] Inject sulfuric acid to adjust the pH value of wastewater to 5, and then add FeSO in an amount of 50mmol / L 4 , according to 1 / 10 of the volume of wastewater into 30% mass concentration of H 2 o 2 Solution, reaction time 10h. The comparison of wastewater quality after treatment according to the stated conditions and before treatment is shown in the following table:

[0063] Table 2-2 Comparison of water quality of water samples before and after Fenton oxidation treatment under suitable conditions

[0064]

[0065] Fenton oxidation treatment by this condition, COD...

Embodiment 3

[0073] Such as figure 2 In the shown treatment process, the raw material treatment of the pig raising wastewater is carried out by means of sand filtration, and the solid particles of the pig raising wastewater are filtered.

[0074] The water quality of pig raising wastewater after filtration is shown in the table:

[0075] Table 3-1 Water Quality Analysis of Pig Raising Wastewater

[0076]

[0077]

[0078] Inject sulfuric acid to adjust the pH value of wastewater to 2, and then add FeSO in an amount of 50mmol / L 4 , according to 1 / 3.5 of the volume of wastewater into 30% mass concentration of H 2 o 2 Solution, reaction time 24h. The comparison of wastewater quality after treatment according to the stated conditions and before treatment is shown in the following table:

[0079] Table 3-2 Comparison of water quality of water samples before and after Fenton oxidation treatment under suitable conditions

[0080]

[0081] Fenton oxidation treatment COD under this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com