Nanocomposite and preparation method thereof

A technology of nanocomposite materials and carbon nanotubes, which is applied in the field of nanocomposite materials and their preparation, can solve the problems of poor dispersion of rubber matrix, lower mechanical properties and low density of rubber products, and achieve improved tensile strength and tear strength, Effects of improved wet skid resistance and increased modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1 A kind of preparation method of nanocomposite material

[0046] Specific steps are as follows:

[0047] (1) Add its weight 5.5% radiation crosslinking agent trimethylolpropane triacrylate in the superfine fully vulcanized carboxylated styrene-butadiene rubber latex, stir for 45min, and obtain superfine fully vulcanized carboxylated styrene-butadiene rubber through 20kGy electron beam irradiation rubber latex;

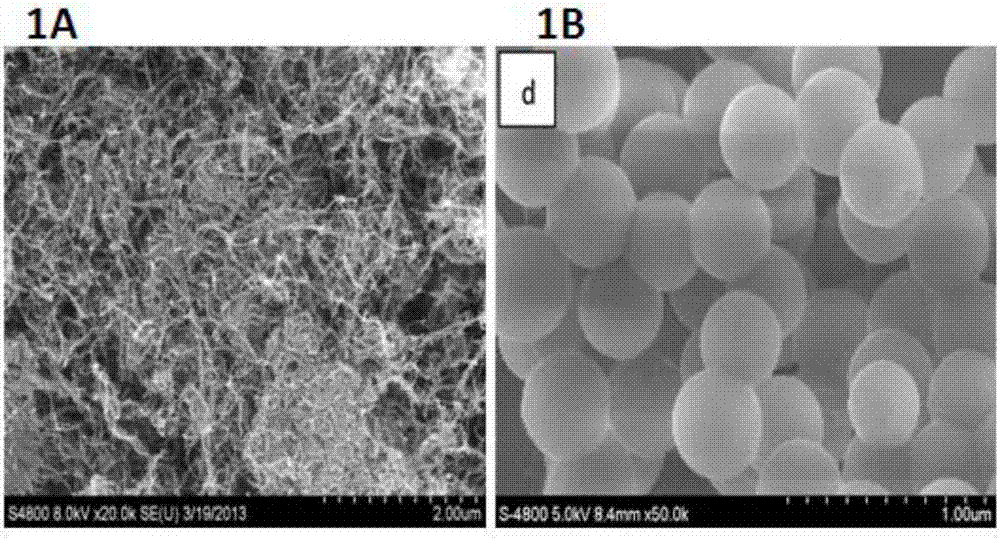

[0048] (2) Pour carbon nanotubes into water, the mass ratio of carbon nanotubes to water is 3.5:96.5, under 2000rpm rotating speed condition, stir 65min, prepare carbon nanotube slurry; Described carbon nanotubes are multi-walled carbon nano Tube;

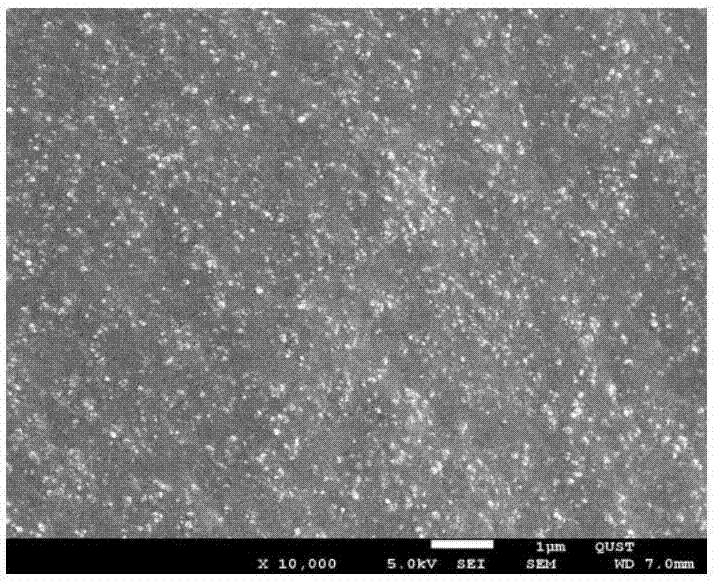

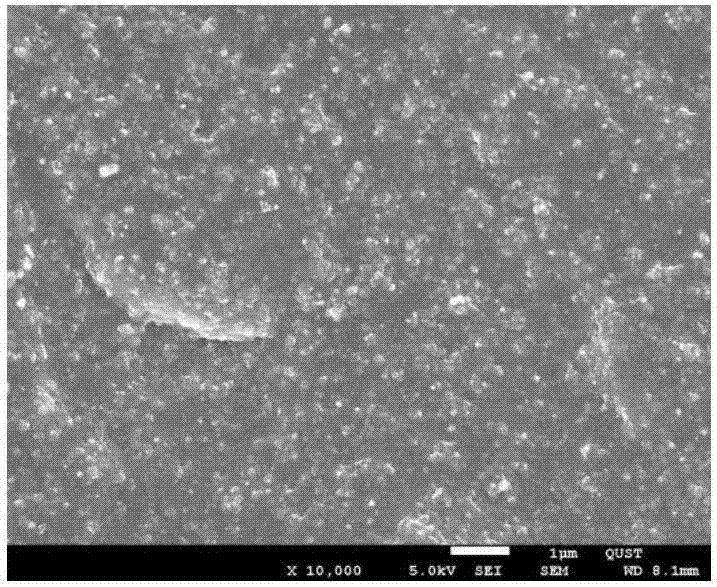

[0049] (3) Mix and stir the ultra-fine fully vulcanized carboxylated styrene-butadiene rubber emulsion and carbon nanotube slurry with a mass ratio of 1:5.5, stir for 40min, and make a composite powder of UFPCSBR and carbon nanotube through pressure spray drying; pressure spray The dry spray pressure i...

Embodiment 2

[0054] Embodiment 2 A kind of preparation method of nanocomposite material

[0055] Specific steps are as follows:

[0056] (1) Add its weight 2% radiation crosslinking agent propane trimethylol triacrylate in the superfine fully vulcanized carboxylated styrene-butadiene rubber latex, stir 35min, through 30kGy electron beam irradiation, obtain superfine fully vulcanized carboxylated styrene-butadiene rubber latex ;

[0057] (2) Pour the single-walled carbon nanotubes into water, the mass ratio of the single-walled carbon nanotubes to water is 1:99, and stir for 50 minutes under the condition of a rotating speed of 1100pm to prepare a carbon nanotube slurry;

[0058] (3) mixing and stirring the superfine fully vulcanized carboxylated styrene-butadiene rubber emulsion and carbon nanotube slurry with a mass ratio of 1:3, stirring for 30 min, and pressure spray drying to obtain a composite powder of UFPCSBR and carbon nanotubes;

[0059] (4) The composite powder obtained in step...

Embodiment 3

[0063] Embodiment 3 A kind of preparation method of nanocomposite material

[0064] Specific steps are as follows:

[0065] (1) add its weight 8% radiation crosslinking agent pentaerythritol tetraacrylate in the superfine fully vulcanized carboxylated styrene butadiene rubber latex, stir 55min, through 25kGy electron beam irradiation, obtain superfine fully vulcanized carboxylated styrene butadiene rubber latex;

[0066] (2) Pour multi-walled carbon nanotubes into water, the mass ratio of carbon nanotubes to water is 0.5-5:99.5-95; under the condition of 2800rpm rotating speed, stir for 100min to prepare carbon nanotube slurry;

[0067] (3) Mixing and stirring the superfine fully vulcanized carboxylated styrene-butadiene rubber emulsion and the carbon nanotube slurry with a mass ratio of 1:8, stirring for 55min, and drying under pressure to obtain a composite powder of UFPCSBR and carbon nanotubes;

[0068] The spray pressure of pressure spray drying is 0.45MPa, the spray inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com