Zero-pressure-level drifting dynamic control sealing system for annular cooler or belt cooler

A dynamic control and sealing system technology, applied in the direction of processing discharged materials, furnaces, lighting and heating equipment, etc., can solve the problems of fume hood thermal deformation, high cost, lower flue gas temperature, etc., and achieve complete sealing without pressure difference , reasonable adjustment and distribution, and the effect of improving power generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing.

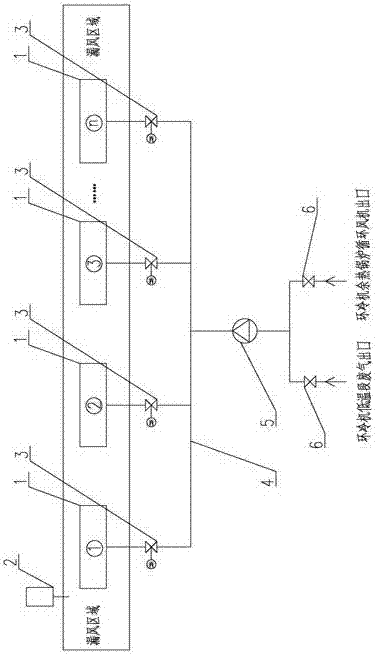

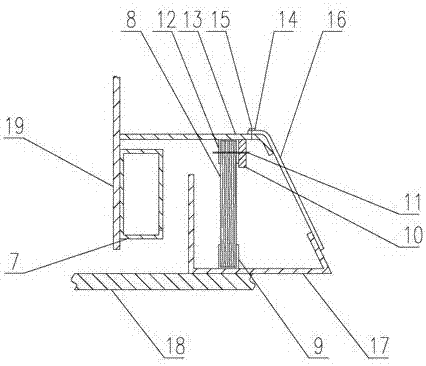

[0015] refer to figure 1 , the system includes zero pressure balance sealing device 1, pressure monitoring control device 2, electric damper 3, hot air pipe 4, high temperature pressure balance fan 5 and hot air inlet valve 6, zero pressure balance sealing device 1 and pressure monitoring control device 2 respectively Set in the air leakage area between the ring cooler or the trolley with cooling machine and the upper fume hood; where n zero pressure balance sealing devices 1 are arranged in the air leakage area, and are fixedly connected to the outside of the upper fume hood, the inlet of the hot air inlet valve 6 The end is connected to the outlet of the circulating fan of the ring cooler or waste heat boiler with cooler, or the inlet end of the hot air inlet valve 6 is connected to the exhaust gas outlet of the ring cooler or the low temperature section of the cooler, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com