Three-in-one direct drinking water system

A three-in-one, direct drinking water technology, applied in beverage preparation devices, fixed filter cartridges, applications, etc., can solve the problems of difficult maintenance, installation, pressure increase, etc., to achieve the effect of reasonable layout and satisfying experience effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

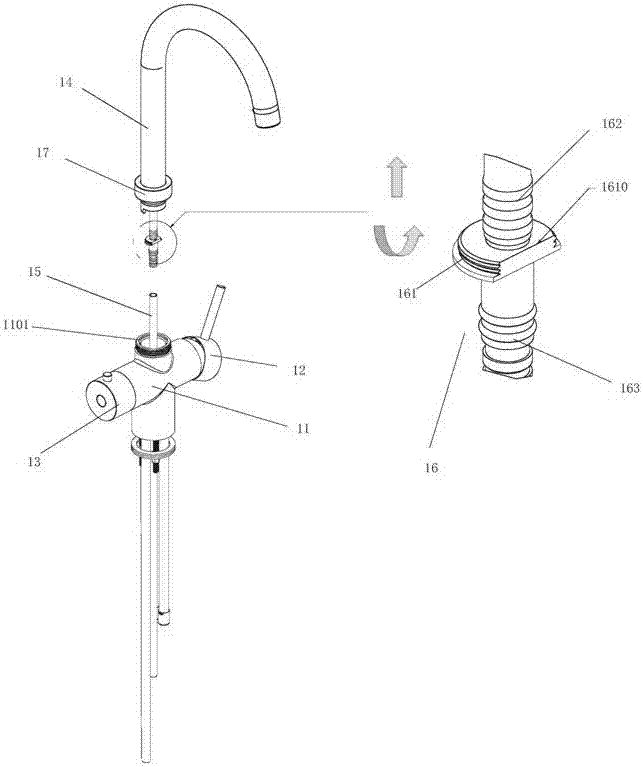

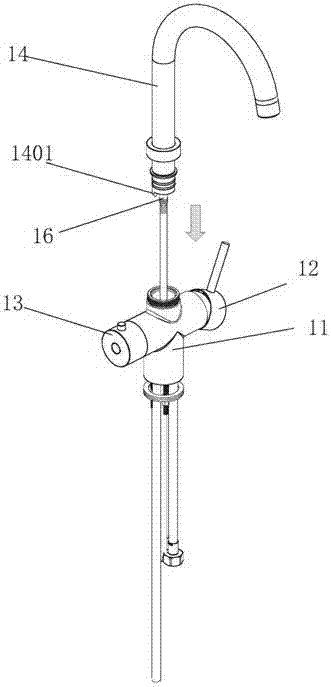

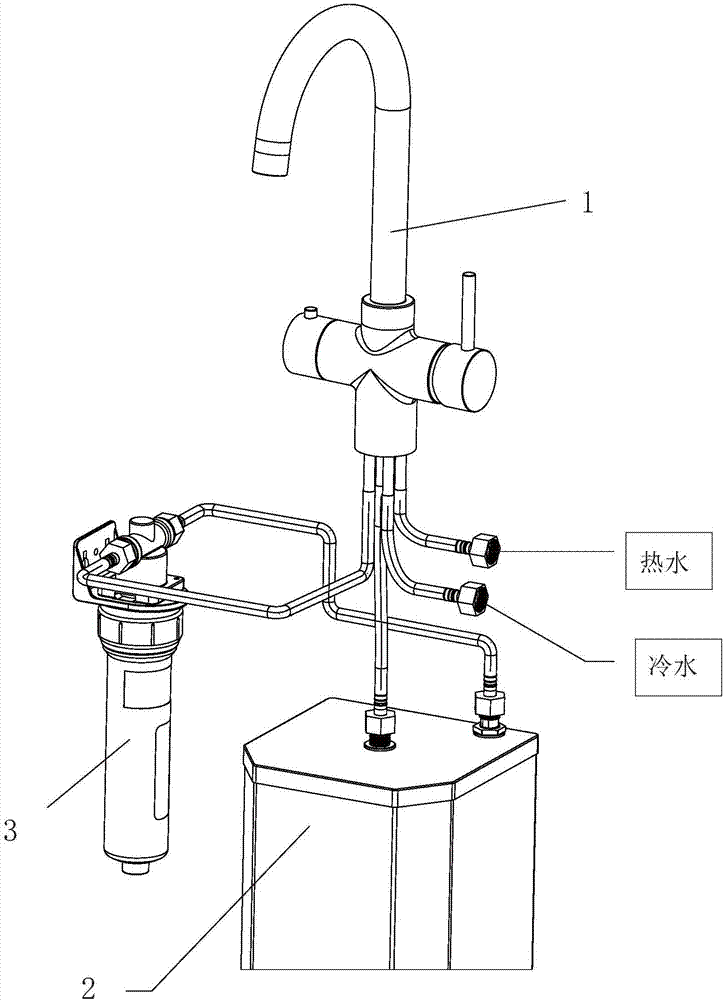

[0039] Example: see Figure 1 to Figure 12 , A three-in-one direct drinking water system, including a three-in-one faucet 1, an instant hot drink machine 2, a water purifier 3. The three-in-one faucet 1 is connected to a water purifier 3 and an instant hot drink machine 2 through a pipeline to form a filter Water and hot drink circuit, in which the three-in-one faucet 1 includes a faucet body 11, a mixing water control valve 12, a direct drinking control valve 13, and a water outlet pipe 14. The mixing water control valve 12 and the direct drinking control valve 13 are installed on both sides of the faucet body 11. The water pipe 14 is set on the top of the faucet body 11. The water inlet end of the faucet body 11 is provided with a cold water inlet and a cold water outlet. Structure; The instant hot drink machine 2 includes a heating inner tank and a connected air storage chamber 201, which can suck the water heated in the inner tank under the Venturi effect so that the inner t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com