Hydraulic system and control method of heavy-duty forging equipment with controllable feed speed

A technology of forging equipment and feed speed, applied in the field of forging, can solve the problems of large gap in international standards, large equipment vibration, poor practicability, etc., and achieve the effects of good sealing, large flow capacity, and sensitive action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

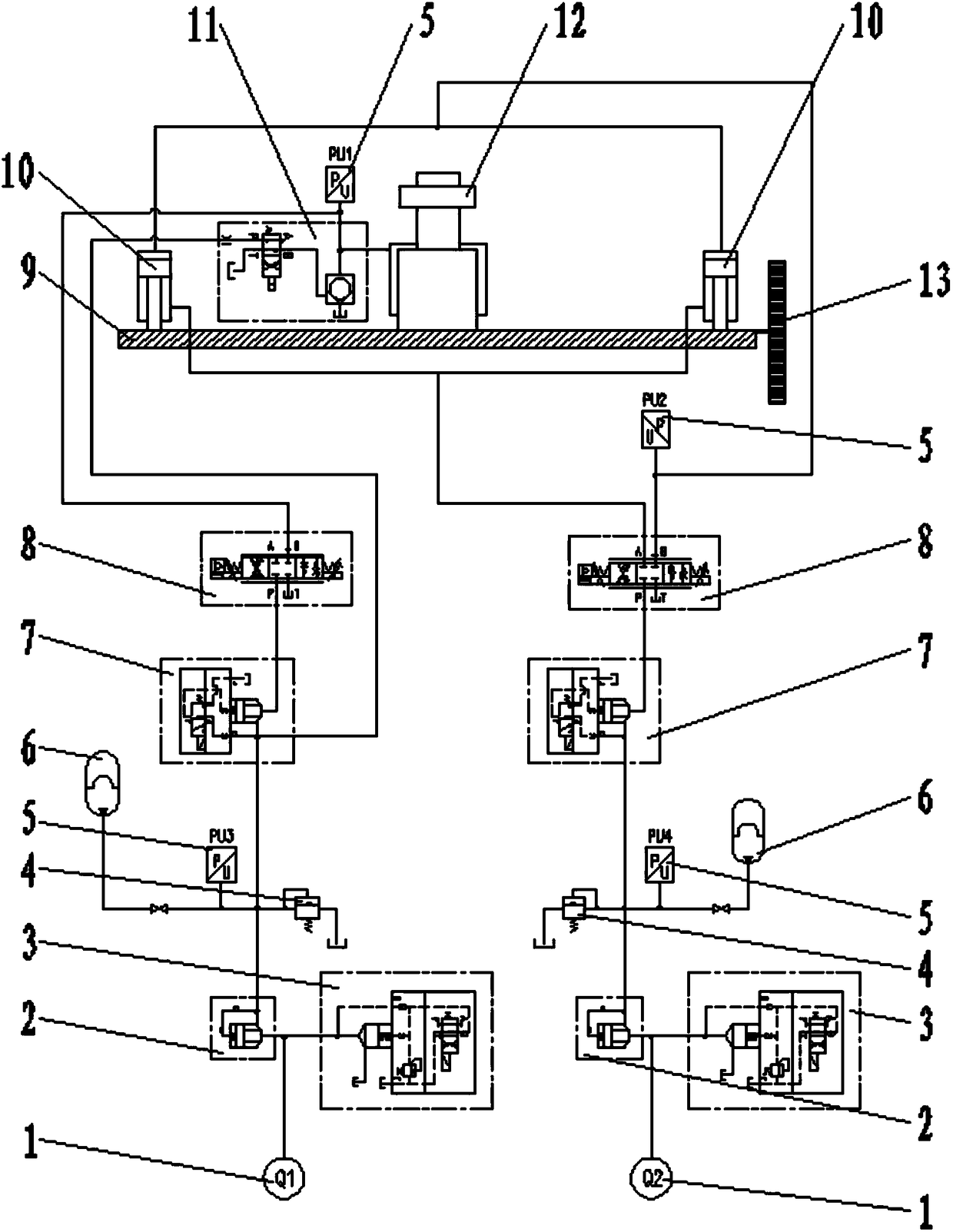

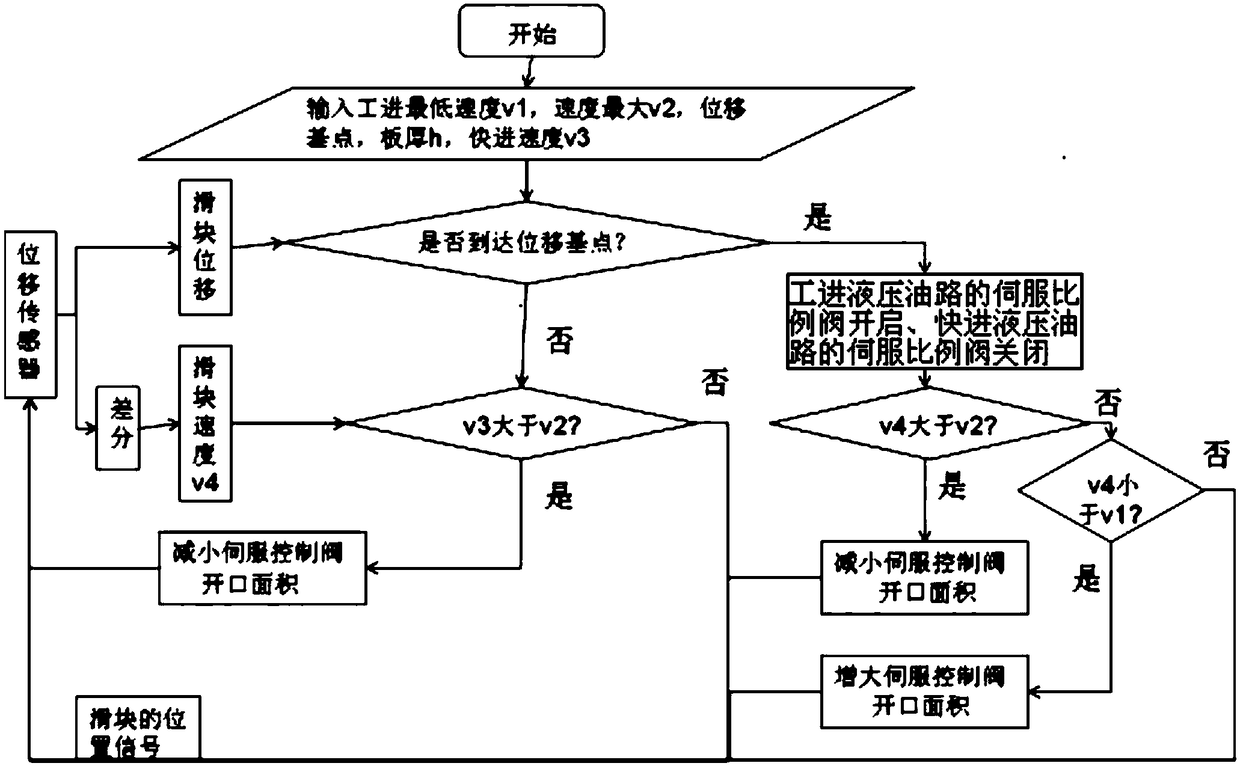

[0021] Such as figure 1 As shown, a hydraulic system for heavy-duty forging equipment with controllable feed speed, including a slider 9, a displacement sensor 13 arranged on the slider 9, and a piston rod connected to the slider 9 and arranged symmetrically on the slider 9 The double-acting fast-forward cylinder 10 (the double-acting fast-forward cylinder 10 has a small bore and a long working stroke, and is symmetrically arranged on the four corners of the slider 9), the fast-forward hydraulic oil circuit, the piston rod and the slider 9 are connected and The single-acting working cylinder 12 located in the middle of the slider 9 (the single-acting working cylinder 12 has a large bore and short effective working stroke), the working hydraulic oil circuit, the human-machine interface and the industrial computer; the fast-forward hydraulic oil circuit a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com