Liner paper production method

A production method and technology of liner paper, which is applied in the field of papermaking technology, can solve the problems of high-grade liner paper, high cost, and large steam consumption that have not been realized in the production of waste paper, so as to increase dryness, save energy, and reduce steam. The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

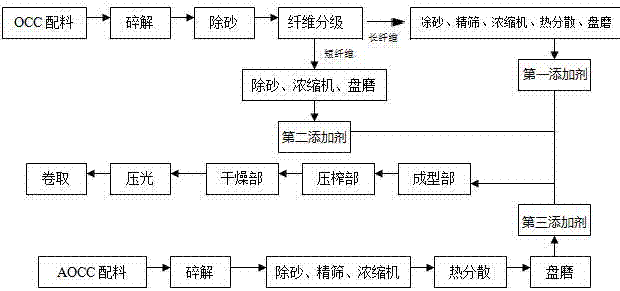

Method used

Image

Examples

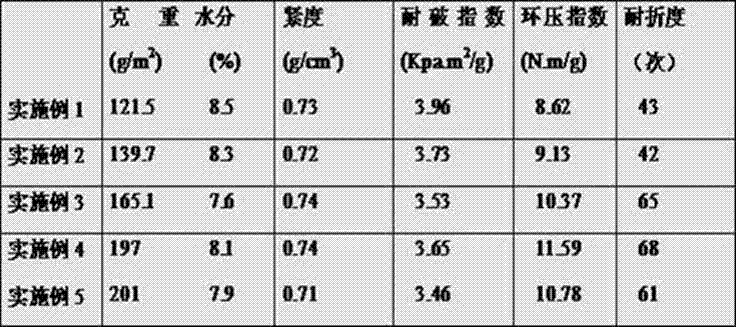

Embodiment 1

[0035] With reference to the production method of a kind of liner paper that often adopts described in the present invention, liner paper is produced, specifically:

[0036] 1) Prepare the surface layer, core layer and bottom layer slurry according to the ratio in Table 1.

[0037] 2) The three-layer pulp is dehydrated on the forming wire part through its respective headbox to form a wet paper sheet, and then compounded on the bottom wire, and is sucked by high vacuum to make a raw cardboard with a dryness of about 22%, which is sent to the press part for further processing. press;

[0038] 3) In the previous step, the original paperboard is mechanically dehydrated through one ordinary press and two shoe presses. After the dryness reaches more than 45%, it is dried in the drying section; the press line pressure is: first press 160KN / M, second press 940KN / M ;

[0039] 3) After the paper web passes through the calender, it forms a parent roll in the roll paper section, and the...

Embodiment 2

[0042] With reference to the production method of a kind of liner paper that often adopts described in the present invention, liner paper is produced, specifically:

[0043] 1) Prepare the surface layer, core layer and bottom layer slurry according to the ratio in Table 2.

[0044] 2) The three-layer pulp is dehydrated on the forming wire part through its respective headbox to form a wet paper sheet, and then compounded on the three-ply wire, and is sucked by high vacuum to make a raw cardboard with a dryness of about 22%, and sent to the press part squeeze;

[0045]3) In the previous step, the raw cardboard is mechanically dehydrated through one ordinary press and two shoe presses. After the dryness reaches more than 45%, it is dried in the drying section; the press line pressure is: first press 180KN / M, second press 1000KN / M ;

[0046] 4) After the paper web passes through the calender, it forms a parent roll in the roll paper section, and then rewinds and cuts it into pro...

Embodiment 3

[0049] With reference to the production method of a kind of liner paper that often adopts described in the present invention, liner paper is produced, specifically:

[0050] 1) Prepare the surface layer, core layer and bottom layer slurry according to the ratio in Table 3.

[0051] 2) The three-layer pulp is dehydrated on the forming wire part through its respective headbox to form a wet paper sheet, and then compounded on the bottom wire, and is sucked by high vacuum to make a raw cardboard with a dryness of about 22%, which is sent to the press part for further processing. press;

[0052] 3) In the previous step, the raw cardboard is mechanically dehydrated through one ordinary press and two shoe presses. After the dryness reaches more than 45%, it is dried in the drying section; the press line pressure is: the first press is 170KN / M, and the second press is 960KN / M. ;

[0053] 3) After the paper web passes through the calender, it forms a parent roll in the roll paper sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com