Graphite paper composite heating plate and preparation method thereof

A composite heating and graphite paper technology, applied in ohmic resistance heating, heating element materials, electric heating devices, etc., can solve the problems of uneven square resistance, damage and high production cost of graphene, and achieve accurate and stable adjustment of heating temperature and production process. Simple and reduce the effect of the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

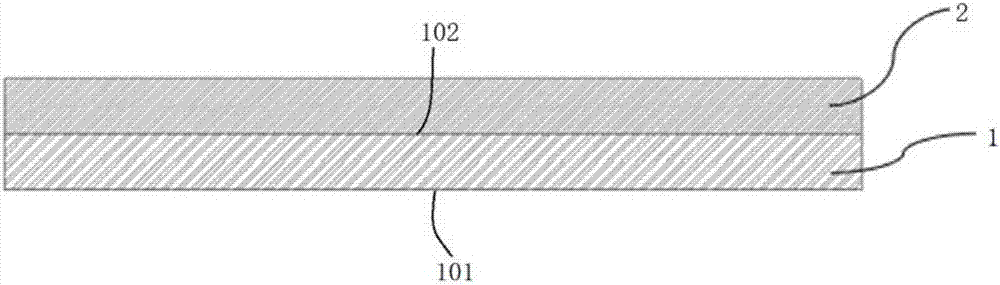

[0096] A graphite paper composite heating plate, such as figure 1 shown, including:

[0097] The heating film 1 includes a first surface 101 and a second surface 102;

[0098] The heat dissipation plate 2 is arranged on the second surface 102 of the heating film 1;

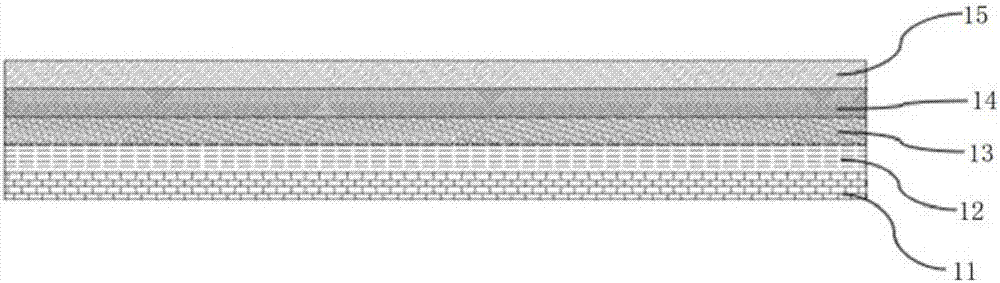

[0099] Such as figure 2 , the heating film 1 includes:

[0100] the second insulating film 11,

[0101] The second resin colloid layer 12 arranged on the surface of the second insulating film,

[0102] The graphite paper heating layer 13 arranged on the surface of the second resin colloid,

[0103] The first insulating film 14 arranged on the surface of the graphite paper heating layer,

[0104] The first resin colloid layer 15 disposed on the surface of the first insulating film,

[0105] Terminal 3, the terminal 3 is connected to the graphite paper heating layer 13, and is used to connect the positive and negative poles of the power supply;

[0106] The heat dissipation plate 2 is attached to the heatin...

Embodiment 2

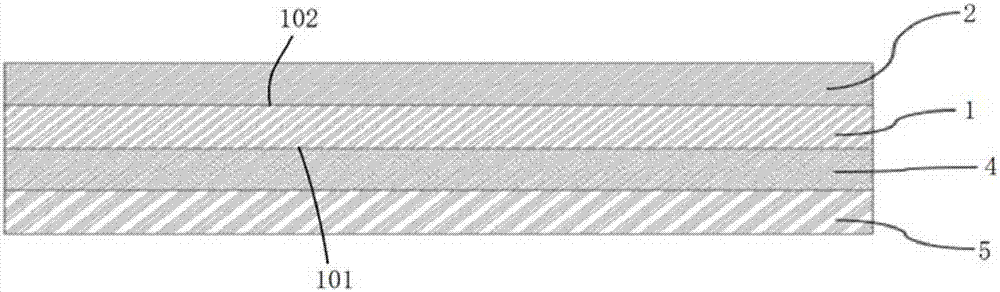

[0111] In this embodiment, as a further preferred embodiment, the graphite paper composite heating plate further includes a reflective layer 4, which is arranged on the first surface 101 of the heating film 1, and is used to receive infrared rays emitted by the heating layer and reflect them back. The surface of the reflective layer 4 is provided with an insulating layer 5, which is used for heat insulation of the graphite paper composite heating plate and the back object.

Embodiment 3

[0113] In this embodiment, as a further preferred embodiment, the pattern of the graphite paper heating layer 13 is described in detail. Such as Figure 4 , 5 , 6, the graphite paper heating layer 13 is a strip-shaped graphite heat-conducting film distributed on the insulating film in an end-to-end U-shaped pattern, and the terminals 3 are respectively located at the two ends of the strip-shaped graphite heat-conducting film. The end-to-end U-shaped graphite thermal conductive film includes a plurality of parallel vertical strips 131 and a plurality of bent sections 132 , and gaps 133 are formed between adjacent vertical strips.

[0114] Preferably, the widths of the vertical strips 131 are equal, and the widths of the slits 133 are equal; further preferably, the width of the vertical strips 131 and the width of the slits 133 are (2.5-4):1, for example: 2.5: 1, 2.6:1, 2.7:1, 2.8:1, 2.9:1, 3:1, 3.1:1, 3.2:1, 3.3:1, 3.4:1, 3.5:1, 3.5:1, 3.7:1, 3.8:1, 3.9:1, 4:1, etc.; the best ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com