White tea and making method thereof

A production method and technology of white tea, which is applied in the field of tea processing, can solve problems such as difficult shape and difficult control of the processing process, and achieve the effects of preventing local water loss and rapid water loss, improving photoelectric properties, and enhancing retention rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

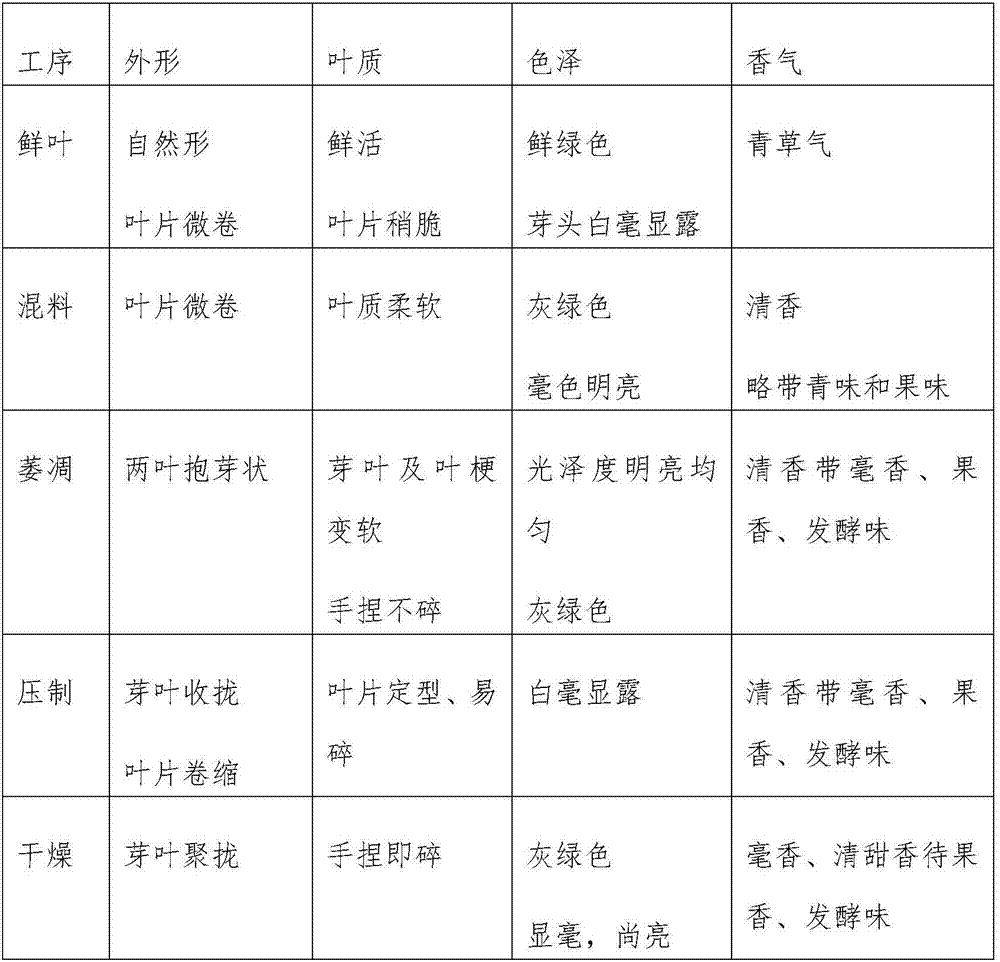

Image

Examples

Embodiment 1

[0033] The white tea of this embodiment includes, by weight, 18 kg of fresh tea leaves, 1 kg of guava juice, 0.1 kg of avocado peel powder, and 0.1 kg of sodium carboxymethyl cellulose as auxiliary materials.

[0034] Its preparation method mainly includes the following steps:

[0035] (1) Primary processing of auxiliary materials: Soak carboxymethyl cellulose sodium in guava juice for 10-15 minutes at a constant temperature of 30°C, then add avocado peel powder and soak for 20-30 minutes;

[0036] (2) Primary processing of raw materials: After removing the fresh tea leaves and washing them, place them in an electromagnetic heater and process until the temperature of the fresh leaves is 30°C;

[0037] (3) Mixing: mix it with auxiliary materials evenly at high speed;

[0038] (4) Withering: wither until the water loss rate of tea leaves is about 28-30%;

[0039] (5) pressed into cake;

[0040] (6) Drying: place it in an electromagnetic heater and dry until the water conten...

Embodiment 2

[0055] The white tea of this embodiment includes, by weight, 20 kg of fresh tea leaves, 3 kg of guava juice, 0.3 kg of avocado peel powder, and 0.5 kg of sodium carboxymethyl cellulose as auxiliary materials.

[0056] Its preparation method mainly includes the following steps:

[0057] (1) Primary processing of auxiliary materials: Soak carmellose sodium in guava juice for 10-15 minutes at a constant temperature of 32°C, then add avocado peel powder and soak for 20-30 minutes;

[0058] (2) Primary processing of raw materials: After removing the fresh tea leaves and washing them, place them in an electromagnetic heater and process until the temperature of the fresh leaves is 30°C;

[0059] (3) Mixing: mix it with auxiliary materials evenly at high speed;

[0060] (4) Withering: wither until the water loss rate of tea leaves is about 28-30%;

[0061] (5) pressed into cake;

[0062] (6) Drying: place it in an electromagnetic heater and dry until the water content of the tea ...

Embodiment 3

[0074] The white tea of the present embodiment includes, by weight, 25 kg of fresh tea leaves, 5 kg of guava juice, 0.5 kg of avocado peel powder, and 0.1 kg of sodium carboxymethyl cellulose as auxiliary materials.

[0075] Its preparation method mainly includes the following steps:

[0076] (1) Primary processing of auxiliary materials: Soak carmellose sodium in guava juice for 10-15 minutes at a constant temperature of 35°C, then add avocado peel powder and soak for 20-30 minutes;

[0077] (2) Primary processing of raw materials: After removing the fresh tea leaves and washing them, place them in an electromagnetic heater and process until the temperature of the fresh leaves is 35°C;

[0078] (3) Mixing: mix it with auxiliary materials evenly at high speed;

[0079] (4) Withering: wither until the water loss rate of tea leaves is about 28-30%;

[0080] (5) pressed into cake;

[0081] (6) Drying: place it in an electromagnetic heater and dry until the water content of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com