Flow sensor for pulmonary function test, pulmonary function tester and application

A flow sensor and lung function technology, applied in the field of flow sensors, can solve the problems of increasing the production process, the complexity of after-sales maintenance, increasing the complexity of instruments, reducing reliability, etc. Correction, the effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

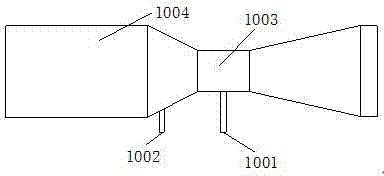

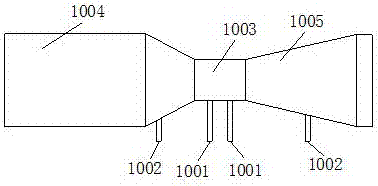

[0060] The experimental group is the flow sensor according to the present invention, the diameter of the exhalation air intake part is 27mm, the cone angle of the first cone is 40 degrees, the throat diameter is 12mm, and the cone angle of the second cone is 25.4 degrees, The suction inlet diameter is 27mm. The distance between the first high pressure tap and the low pressure tap is 20mm, and the distance between the second high pressure tap and the low pressure tap is 25mm.

[0061] The control group is a dual-hole flow sensor of the prior art, the diameter of the expiratory inlet part is 27 mm, the cone angle of the first cone is 40 degrees, the diameter of the throat part is 12 mm, and the cone angle of the second cone is 25.4 degrees , The diameter of the suction inlet is 27mm. The distance between the first high pressure tap and the low pressure tap is 20mm.

[0062] The flow sensor of the experimental group and the flow sensor of the control group were compared with th...

Embodiment 2

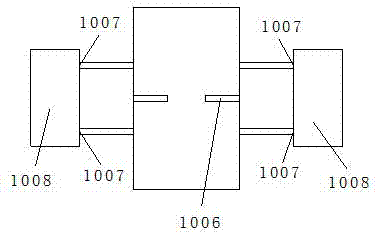

[0069] Measure the maximum pressure difference of the flow sensor of the embodiment 1 experimental group, the expiratory flow maximum range is 900L / min, and the corresponding pressure difference is 10kPa when the maximum flow; the inspiratory flow maximum range is 600L / min, and the corresponding pressure difference is 10kPa when the maximum flow. Therefore, the first differential pressure sensor and the second differential pressure sensor can use differential pressure sensors with the same range. The two sensors were calibrated by experimentally testing flow and differential pressure data (see Table 3). For specific calibration, connect two differential pressure sensors in parallel and apply the same differential pressure, and take two differential pressure points of 1kPa and 5kPa for linear calibration.

[0070] table 3

[0071] Expiratory flow value (L / min)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com