Multitube-structure ozone generator and manufacture method thereof

A technology of ozone generator and tube structure, which is applied in the direction of ozone preparation, chemical instruments and methods, and discharge method to prepare ozone, etc., to achieve the effect of improving the cooling effect and increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] Specific implementation 1

[0058] Such as figure 1 As shown, the technical solution adopted by the ozone generator with multi-tube structure of the present invention includes two parts: the tube side of the path from oxygen to ozone and the shell side of the cooling water path; the tube side includes the lower tube box 1 at the bottom and upper tube box 2 at the top, where:

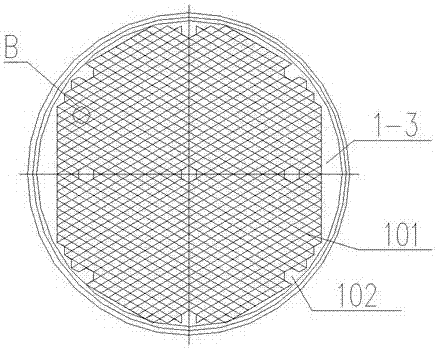

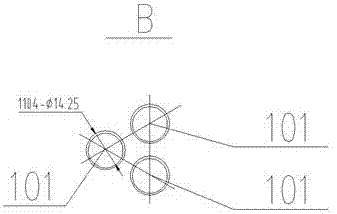

[0059] Such as Figure 1 ~ Figure 4 and Figure 6 As shown, the lower tube box 1 is composed of a bottom plate 1-1, a lower connecting tube 1-2, a lower tube plate 1-3, a lower cylinder body 1-4, a perforated plate 1-5 and a silk screen 1-6. There are 1104 heat exchange tube holes 101 and 9 fixing rod holes 102 drilled on the tube plate 1-3, and 1104 high-voltage discharge tubes for positioning the high-voltage discharge tubes are drilled on the porous plate 1-5. The positioning hole 104, the base plate 1-1 and the lower tube plate 1-3 are welded with the cylinder body 1-4, and the lower conne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com