Sludge drying and conveying device

A conveying device and sludge drying technology, which is applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc. Low equipment efficiency and other issues, to achieve the effect of simple structure, small equipment footprint, and not easy to dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

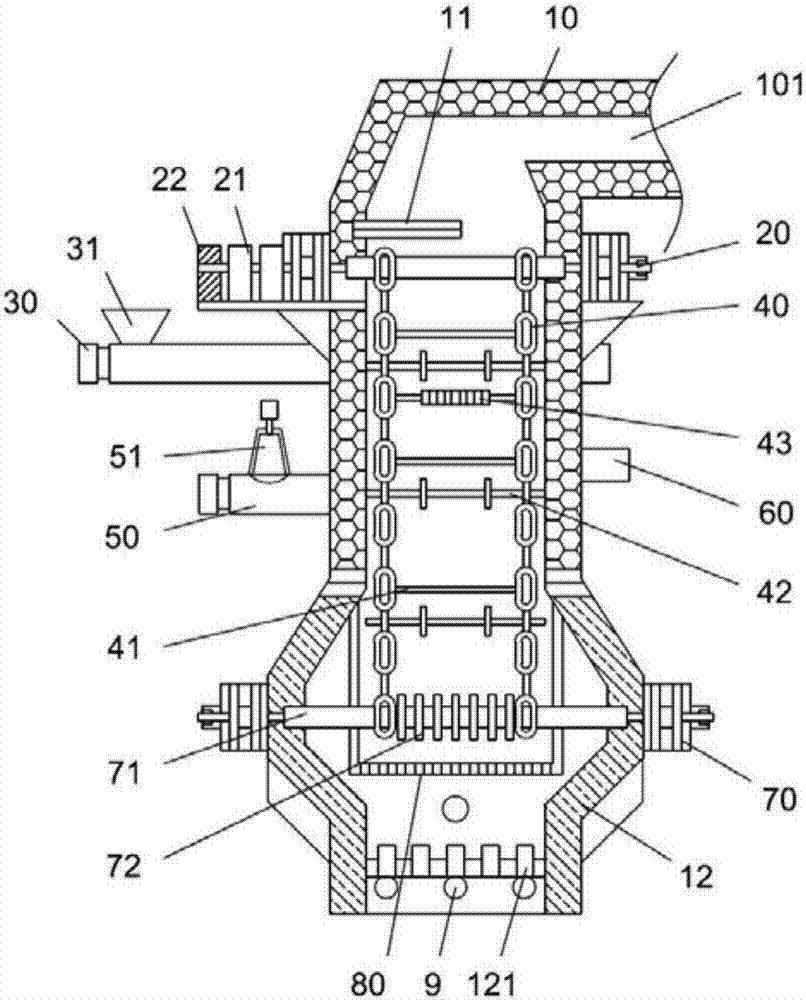

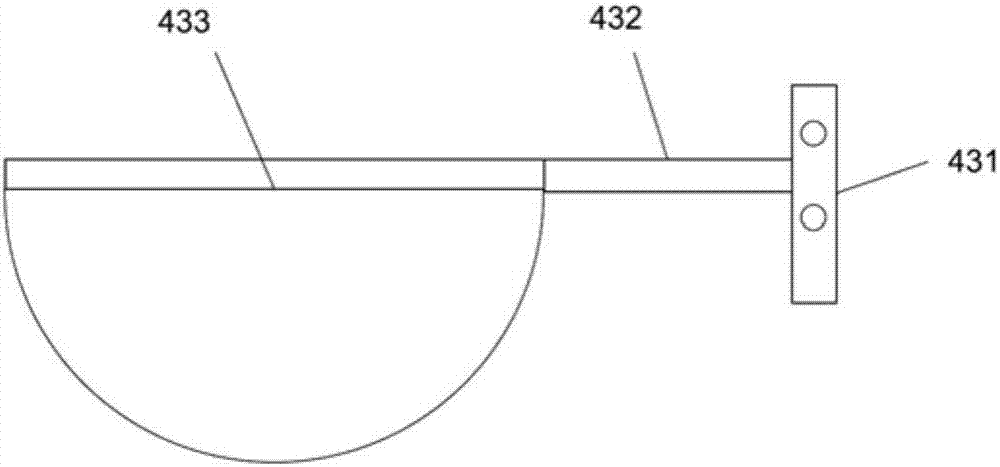

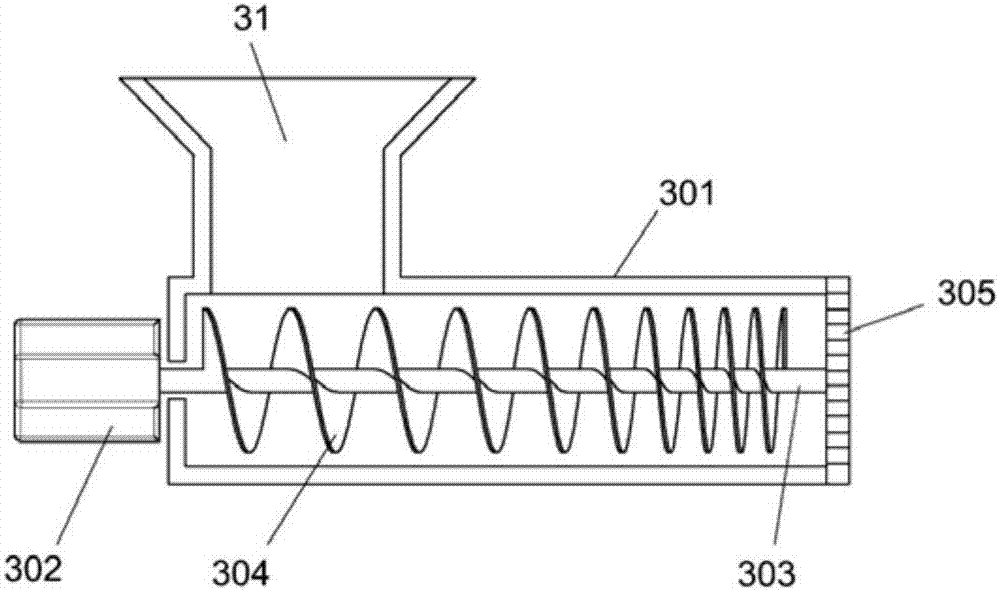

[0016] Such as Figure 1-3 As shown, a sludge drying conveying device includes a conveying channel, a chain hoist is arranged inside the conveying channel, an exhaust gas discharge outlet 101 is arranged at the upper end of the conveying channel, and a heating and drying generator 9 is arranged below the conveying channel; the chain The left side of the upper end of the hoist is provided with a screw feeder 30, and the upper right side of the chain hoist is provided with a discharge machine; the conveying channel is composed of an upper heat preservation section 10, a middle drying section and a lower refractory section 12, and the waste gas discharge outlet 101 is connected to The upper heat preservation section 10 is connected, the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com