Plant greenhouse automatic control system and method

An automatic control system and greenhouse technology, applied in control/regulation systems, botany equipment and methods, non-electric variable control, etc., can solve the problems of unable to design a standard and stable external growth environment for plants, and improve growth efficiency and quality , increase production, moderate humidity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

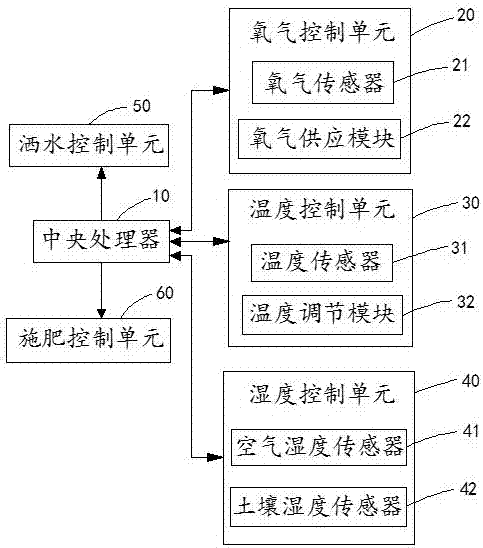

[0031] Such as figure 1 As shown, the plant greenhouse automatic control system of the present embodiment includes a plant greenhouse independent of the outside world, a central processing unit 10, an oxygen control unit 20, a temperature control unit 30, a humidity control unit 40, and a sprinkler control unit 50. , Fertilization control unit 60 .

[0032] The central processing unit 10 is respectively connected to an oxygen control unit 20 , a temperature control unit 30 , a humidity control unit 40 , a watering control unit 50 , and a fertilization control unit 60 .

[0033] The oxygen control unit 20 includes: an oxygen sensor 21 for detecting the oxygen concentration in the greenhouse, and an oxygen supply module 22 for supplying oxygen to the greenhouse.

[0034] The temperature control unit 30 includes: a temperature sensor 31 for detecting the temperature of the air in the greenhouse, and a temperature adjustment module 32 for absorbing or releasing heat.

[0035] Th...

Embodiment 2

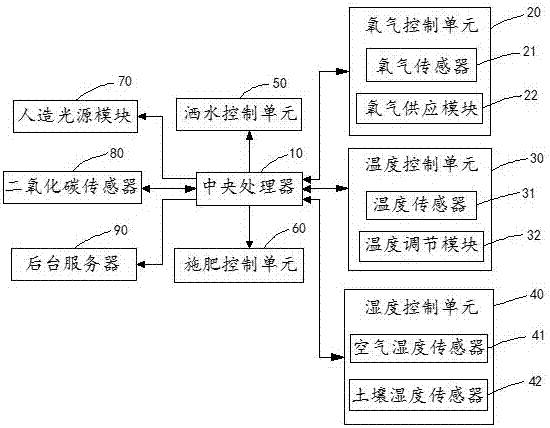

[0040] Such as figure 2 As shown, the plant greenhouse automatic control system of the present embodiment includes a plant greenhouse independent of the outside world, a central processing unit 10, an oxygen control unit 20, a temperature control unit 30, a humidity control unit 40, and a sprinkler control unit 50. , fertilization control unit 60, artificial light source module 70, carbon dioxide sensor 80, background server 90. The greenhouse is selected from one of a greenhouse, a shed, a green house, and a net room.

[0041] The central processing unit 10 is respectively connected to an oxygen control unit 20 , a temperature control unit 30 , a humidity control unit 40 , a sprinkling control unit 50 , a fertilization control unit 60 , an artificial light source module 70 , a carbon dioxide sensor 80 , and a background server 90 .

[0042] The oxygen control unit 20 includes an oxygen sensor 21 for measuring the oxygen concentration in the greenhouse, and an oxygen supply ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com