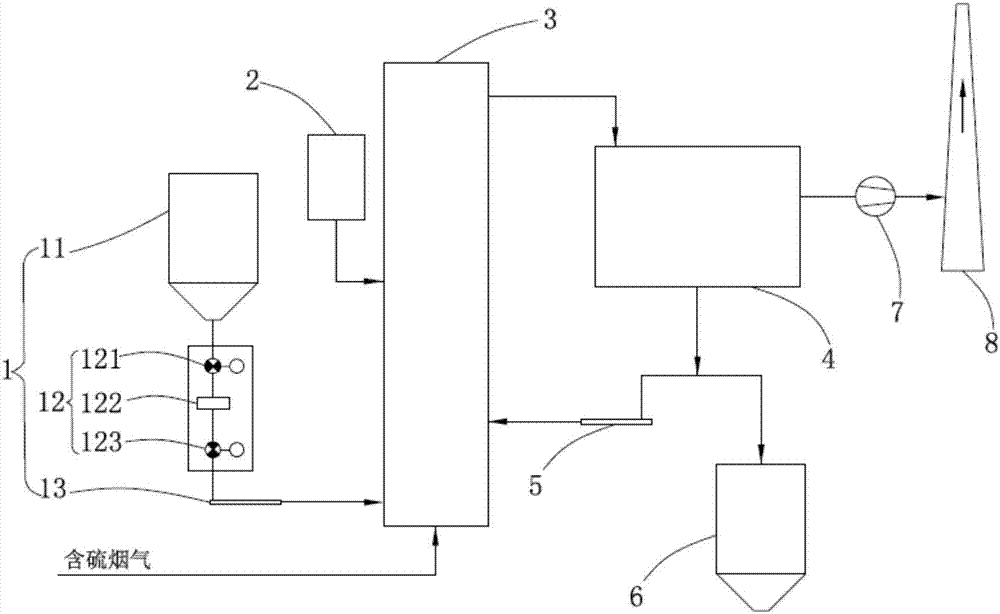

Semi-dry desulfurization system and semi-dry desulfurization process by aid of fly ash

A semi-dry desulfurization and fly ash technology, which is applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of high production cost and low utilization rate of fly ash, and achieve large transportation volume and reduce digestion Device or pulping device, the effect of preventing bag paste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention provides many applicable inventive concepts that can be embodied in numerous specific contexts. The specific examples described in the following embodiments of the present invention are only used as illustrations of specific embodiments of the present invention, and are not intended to limit the scope of the present invention.

[0043] The principle of the semi-dry desulfurization process utilizing fly ash provided by the invention is:

[0044] Pulverized coal burns in a fluidized state in the furnace of the boiler, and most of the combustibles are burned in the furnace, and at the same time produce SO 2 In the high-temperature flue gas such as sulfur-containing gases, some non-combustibles are cooled by the boiler tail to form fly ash. Fly ash is the main solid waste discharged from coal-fired boilers and also exists in the high-temperature flue gas after combustion.

[0045] The main composition of fly ash is SiO 2 、Al 2 o 3 , Fe2 o 3 , CaO ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com