Device for generating ultrahigh pressure

A technology of ultra-high pressure and high-pressure components, which is applied in the field of high-pressure devices, can solve the problems of small samples and uneven pressure fields, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

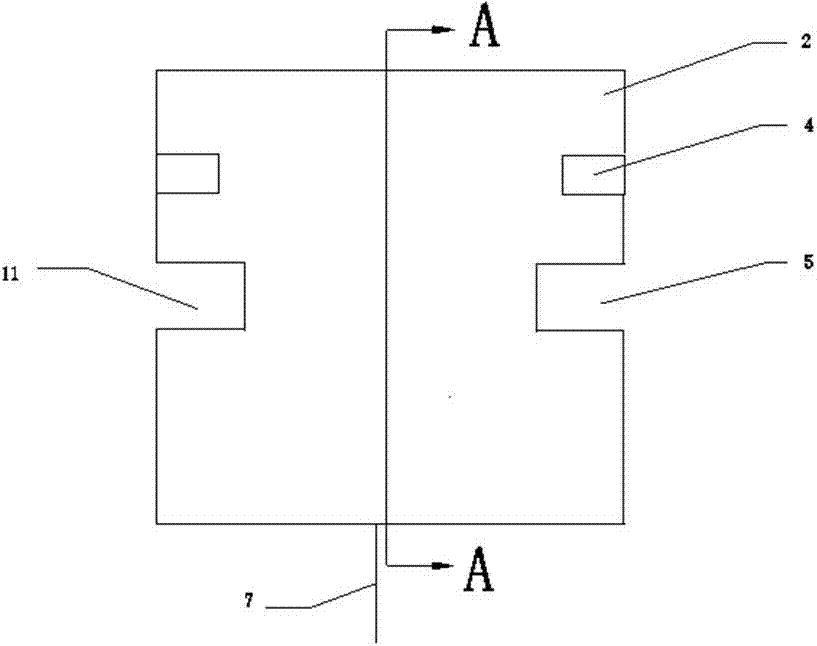

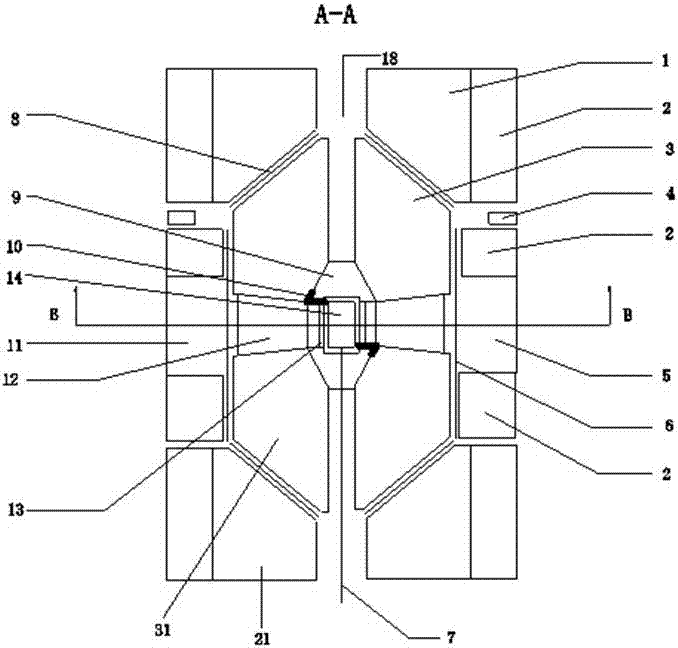

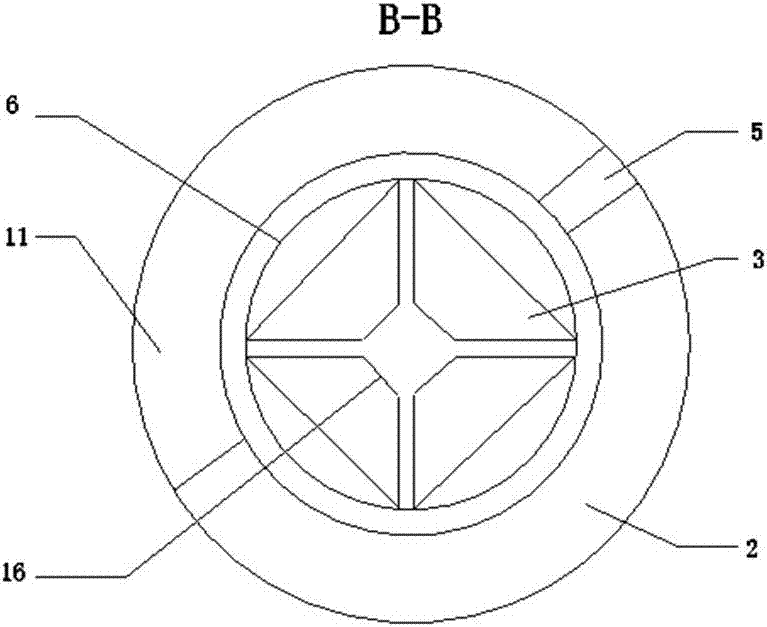

[0028] figure 1 It is the front view of the device for generating ultra-high pressure of the present invention, figure 2 for figure 1 Middle A-A sectional view, image 3 for figure 2 Middle B-B center sectional view, Figure 4 It is a structural schematic diagram of the high-voltage assembly in the present invention, Figure 5 It is a partial schematic diagram of the present invention, that is, a schematic diagram of the structure of the secondary anvil with an arc surface on the outside. exist Figure 1 to Figure 5 Among them, the device for generating ultra-high pressure of the present invention includes a primary anvil I1, a primary anvil II21, eight slider-type secondary anvils, a supporting steel ring 2, a gasket 12, an incident window 5, Exit window 11, thermocouple 7, copper foil 8 and high voltage components. Among them, the secondary anvils include four secondary anvils I3 and four secondary anvils II31 with the same structure, and the end faces 16 of the sec...

Embodiment 2

[0037] The structure of this embodiment is the same as that of Example 1, except that when the sample is subjected to high temperature and high pressure experiments, the material of the secondary anvil is diamond; when it is used for ruby pressure measurement or spectrum measurement, the material of the secondary anvil is Made of transparent aluminum oxide. Bakelite insulation sheets are arranged between the primary anvil I1 and the secondary anvil I3, and between the primary anvil II21 and the secondary anvil II31.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com