Eu-Bi codoped tungsten bronze structure light emitting ferroelectric ceramic material with high light emitting heat stability and preparation method thereof

A technology of ferroelectric ceramics and thermal stability, applied in the field of ceramic materials, can solve the problems of single material performance, deterioration of electrical performance, and limited application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

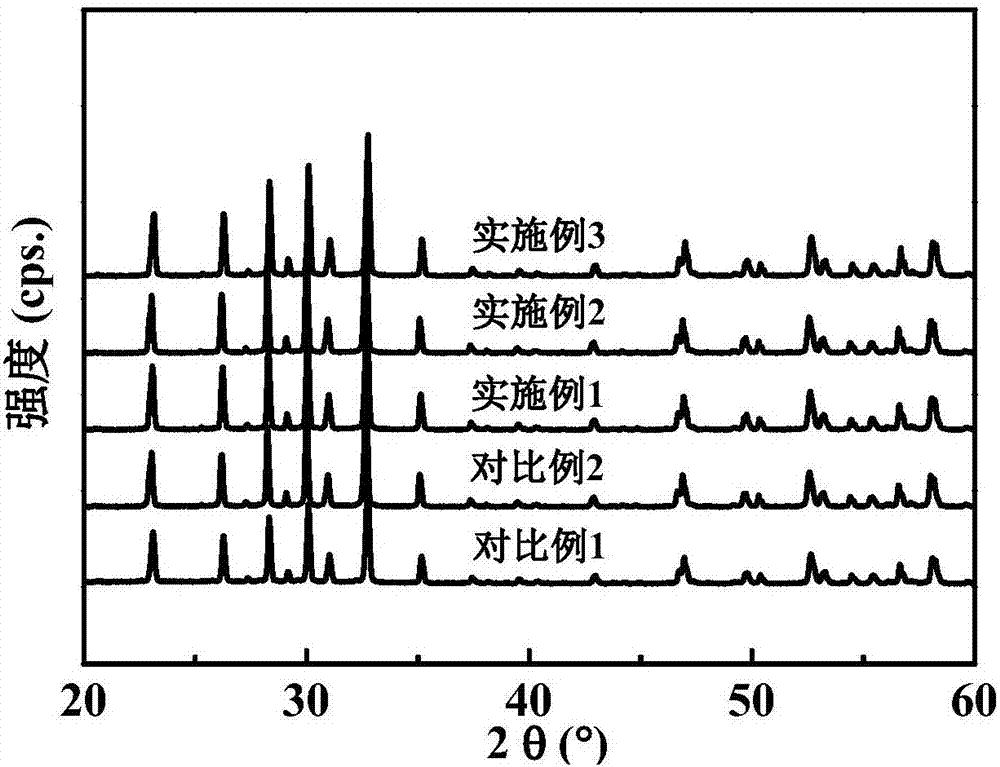

Embodiment 1

[0020] 1. According to Sr 1.90 Ca 0.15 Na 0.801 Eu 0.03 Bi 0.003 Nb 5 o 15 The stoichiometry was weighed separately for Na with a purity of 99.80%. 2 CO 3 0.8409g of SrCO with a purity of 99.00% 3 5.6016g of Nb with a purity of 99.99% 2 o 5 13.1394 g of CaCO with a purity of 99.00% 3 0.2998g of Eu with a purity of 99.99% 2 o 3 0.1044g of Bi with a purity of 99.99% 2 o 3 0.0138g, put it into a nylon jar, use zirconium balls as the balls and absolute ethanol as the ball milling medium, use a ball mill at 401 rpm for 24 hours, place it in a drying oven at 80°C for 15 hours, and grind it with a mortar for 30 Minutes, pass through 80 mesh sieves, obtain raw material mixture.

[0021] 2. Put the raw material mixture in an alumina crucible and compact it with an agate rod to make the compacted density 1.5g / cm 3 , cover it, place it in a resistance furnace, heat it up to 1220°C at a rate of 3°C / min and pre-fire it for 6 hours, cool it down to room temperature natu...

Embodiment 2

[0024] In step 1 of this embodiment, according to Sr 1.90 Ca 0.15 Na 0.795 Eu 0.03 Bi 0.005 Nb 5 o 15 The stoichiometry was weighed separately for Na with a purity of 99.80%. 2 CO 3 0.8345g of SrCO with a purity of 99.00% 3 5.6008g of Nb with a purity of 99.99% 2 o 5 13.1375 g of CaCO with a purity of 99.00% 3 0.2998g of Eu with a purity of 99.99% 2 o 3 0.1044g of Bi with a purity of 99.99% 2 o 3 0.0230g, and the other steps were the same as in Example 1 to obtain a Eu-Bi co-doped tungsten bronze structure luminescent ferroelectric ceramic material.

Embodiment 3

[0026] In step 1 of this embodiment, according to Sr 1.90 Ca 0.15 Na 0.786 Eu 0.03 Bi 0.008 Nb 5 o 15 The stoichiometry was weighed separately for Na with a purity of 99.80%. 2 CO 3 0.8249g of SrCO with a purity of 99.00% 3 5.5996g of Nb with a purity of 99.99% 2 o 5 13.1347 g of CaCO with a purity of 99.00% 3 0.2997g of Eu with a purity of 99.99% 2 o 3 0.1043g of Bi with a purity of 99.99% 2 o 3 0.0368g, and the other steps were the same as in Example 1 to obtain a Eu-Bi co-doped tungsten bronze structure luminescent ferroelectric ceramic material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| remanent polarization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com