Special paint for environmental-friendly water-based shield pump and its preparation and using method

A shielded pump, an environment-friendly technology, applied in the field of coatings, can solve problems such as hardness, poor water resistance, high VOC content, and pollute the environment, and achieve the effects of low VOC content, convenient operation, and good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

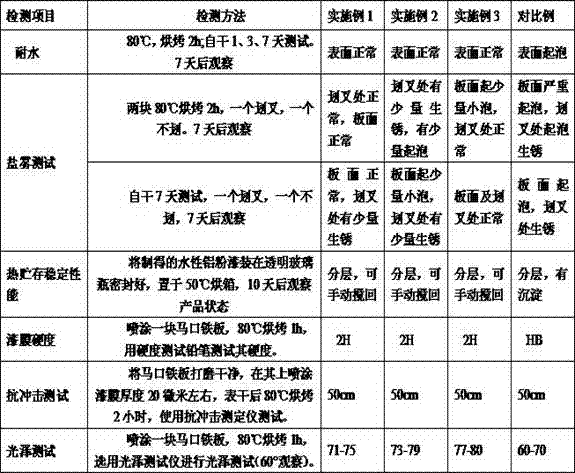

Examples

Embodiment 1

[0052] An environmentally friendly water-based canned pump special paint, the formula includes the following components in mass percentage:

[0053] Aqueous dispersion of solid bisphenol A epoxy resin 60%,

[0054] Defoamer 0.74%,

[0055] Dispersant 1.56%,

[0056] Coalescing agent 1.23%,

[0057] Wetting agent 0.79%,

[0058] Anti-flash rust agent 2.72%,

[0059] Titanium dioxide 7.89%,

[0060] Phthalo Green 5.36%,

[0062] Ultramarine 0.69%,

[0063] Thixotropic anti-settling agent 0.57%,

[0064] Thickener 1.38%,

[0065] Deionized water 15%,

[0066] Prepared by mixing and stirring.

[0067] The aqueous dispersion of the solid bisphenol A epoxy resin is STW703A from Shanghai Xinhua Resin Factory; the water-based epoxy resin curing agent is STW703B from Shanghai Xinhua Resin Factory.

[0068] The defoamer is a mixture of TEGO's defoaming agent Tego-902w and BYK's defoaming agent BYK-024, the ratio is 1:1; the dispersant is TEGO dis...

Embodiment 2

[0080] An environmentally friendly water-based canned pump special paint, the formula includes the following components in mass percentage:

[0081] Aqueous dispersion of solid bisphenol A epoxy resin 70%,

[0082] Defoamer 0.44%,

[0083] Dispersant 1.29%,

[0084] Coalescing agent 0.78%,

[0085] Wetting agent 0.21%,

[0086] Anti-flash rust agent 1.21%,

[0087] Titanium dioxide 5.35%,

[0088] Phthalocyanine 2.23%,

[0090] Ultramarine 0.22%,

[0091] Thixotropic anti-settling agent 0.31%,

[0092] Thickener 0.53%,

[0093] Deionized water 16%,

[0094] Prepared by mixing and stirring.

[0095] The aqueous dispersion of the solid bisphenol A epoxy resin is STW703A from Shanghai Xinhua Resin Factory; the water-based epoxy resin curing agent is STW703B from Shanghai Xinhua Resin Factory.

[0096] The defoamer is a mixture of TEGO's defoaming agent Tego-902w and BYK's defoaming agent BYK-024, the ratio is 1:1; the dispersant is TEGO ...

Embodiment 3

[0108] An environmentally friendly water-based canned pump special paint, the formula includes the following components in mass percentage:

[0109] Aqueous dispersion of solid bisphenol A epoxy resin 63%,

[0110] Defoamer 0.75%,

[0111] Dispersant 1.95%,

[0112] Coalescing agent 1.23%,

[0113] Wetting agent 0.79%,

[0114] Anti-flash rust agent 2.79%,

[0115] Titanium dioxide 7.89%,

[0116] Phthalocyanine 2.36%,

[0117] Barium sulfate 2.06%,

[0118] Ultramarine 0.3%,

[0119] Thixotropic anti-settling agent 0.5%,

[0120] Thickener 1.38%,

[0121] Deionized water 15%,

[0122] Prepared by mixing and stirring.

[0123] The aqueous dispersion of the solid bisphenol A epoxy resin is STW703A from Shanghai Xinhua Resin Factory; the water-based epoxy resin curing agent is STW703B from Shanghai Xinhua Resin Factory.

[0124] The defoamer is a mixture of TEGO's defoaming agent Tego-902w and BYK's defoaming agent BYK-024, the ratio is 1:1; the dispersant is TEGO di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com