High-strength aluminum-base material and preparation method thereof

An aluminum-based material and high-strength technology, applied in the field of metal materials, can solve the problems of reducing strength, impairing performance, and reducing the hardness of aluminum-based materials, etc., to achieve the effects of enhancing strength, enhancing mechanical properties, and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

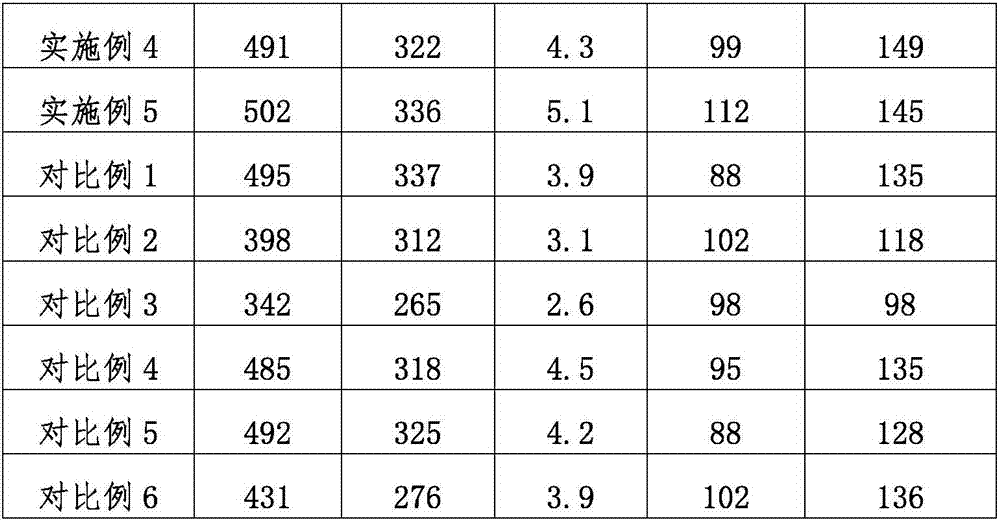

Examples

Embodiment 1

[0021] A high-strength aluminum-based material, which contains the following raw materials in parts by weight: 75kg of pure aluminum, 35kg of aluminum borate, 5kg of nano-carbon fiber, 4kg of composite metal powder, and 10kg of reinforcing particles;

[0022] The reinforcing particles are composed of a reinforcing agent and a coating agent, wherein the mass ratio of the coating agent to the reinforcing agent is 1.5:1.

[0023] The reinforcing agent is prepared by mixing TiB2 and Al2O3 at a mass ratio of 1:0.35.

[0024] The coating agent is preferably zinc.

[0025] The composite metal powder includes copper powder, vanadium powder, and chromium powder. Based on the total weight of the aluminum-based material, the amount of copper powder added is 0.8% of the total weight of the aluminum-based material, and the amount of added vanadium powder is 0.8% of the aluminum-based material. 0.3% of the total weight, and the addition of chromium powder is 1% of the total weight of the a...

Embodiment 2

[0031] A high-strength aluminum-based material, the aluminum-based material contains the following raw materials by weight: 105kg of pure aluminum, 55kg of aluminum borate, 25kg of nano-carbon fiber, 15kg of composite metal powder, and 30kg of reinforcing particles;

[0032] The reinforcing particles are composed of a reinforcing agent and a coating agent, wherein the mass ratio of the coating agent to the reinforcing agent is 1.8:1.

[0033] The reinforcing agent is prepared by mixing TiB2 and Al2O3 at a mass ratio of 1:0.45.

[0034] The coating agent is preferably nickel.

[0035] The composite metal powder includes copper powder, vanadium powder, and chromium powder. Based on the total weight of the aluminum-based material, the amount of copper powder added is 1.2% of the total weight of the aluminum-based material, and the amount of added vanadium powder is 1.2% of the total weight of the aluminum-based material. 0.5% of the total weight, and the addition of chromium pow...

Embodiment 3

[0041] A high-strength aluminum-based material, which contains the following raw materials in parts by weight: 86kg of pure aluminum, 45kg of aluminum borate, 18kg of nano-carbon fiber, 9kg of composite metal powder, and 20kg of reinforcing particles;

[0042] The reinforcing particles are composed of a reinforcing agent and a coating agent, wherein the mass ratio of the coating agent to the reinforcing agent is 1.7:1.

[0043] The reinforcing agent is prepared by mixing TiB2 and Al2O3 at a mass ratio of 1:0.4.

[0044] The coating agent is preferably nickel.

[0045] The composite metal powder includes copper powder, vanadium powder, and chromium powder. Based on the total weight of the aluminum-based material, the amount of copper powder added is 1% of the total weight of the aluminum-based material, and the amount of added vanadium powder is 1% of the total weight of the aluminum-based material. 0.4% of the total weight, and the addition of chromium powder is 1.5% of the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com