Detachable prefabricated assembly type square steel tube concrete column base joint

A technology for concrete-filled steel tubular columns and concrete columns, which is applied in basic structural engineering, architecture, building construction, etc., can solve the problems of extensive design and construction, large resource and energy consumption, and large labor demand, so as to reduce welding work and formwork. work, ensure construction quality, and improve the effect of assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

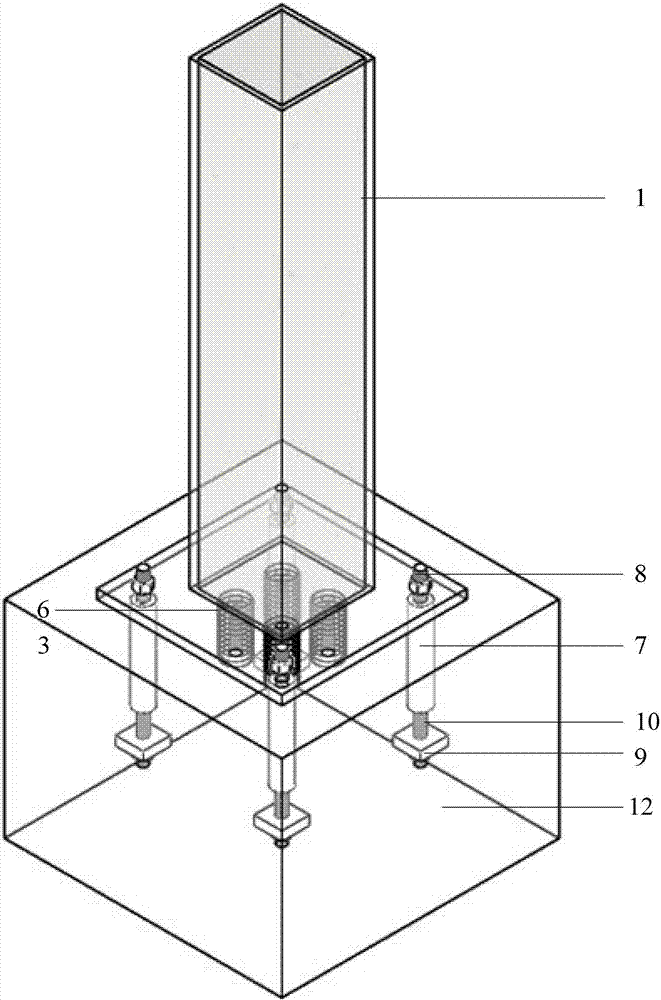

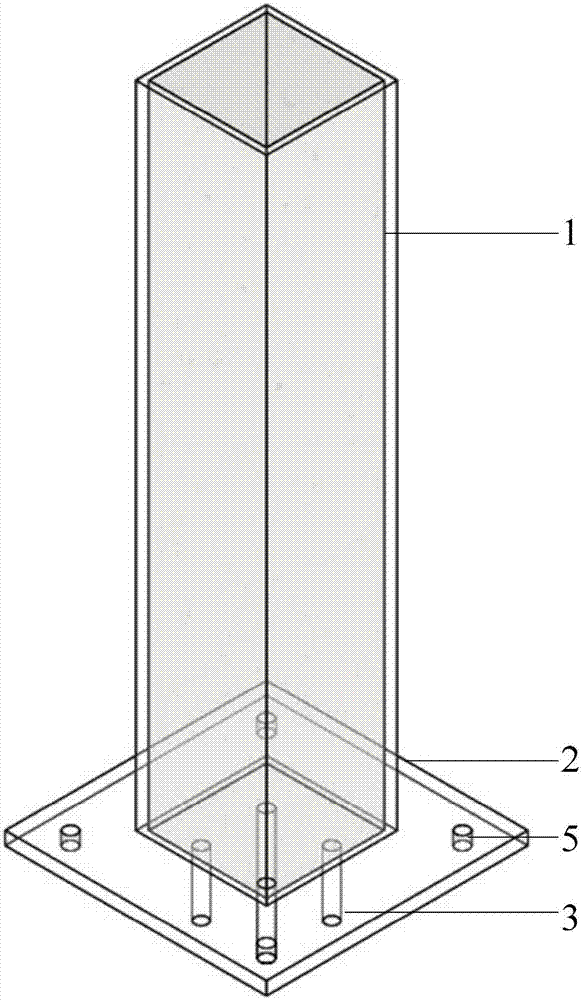

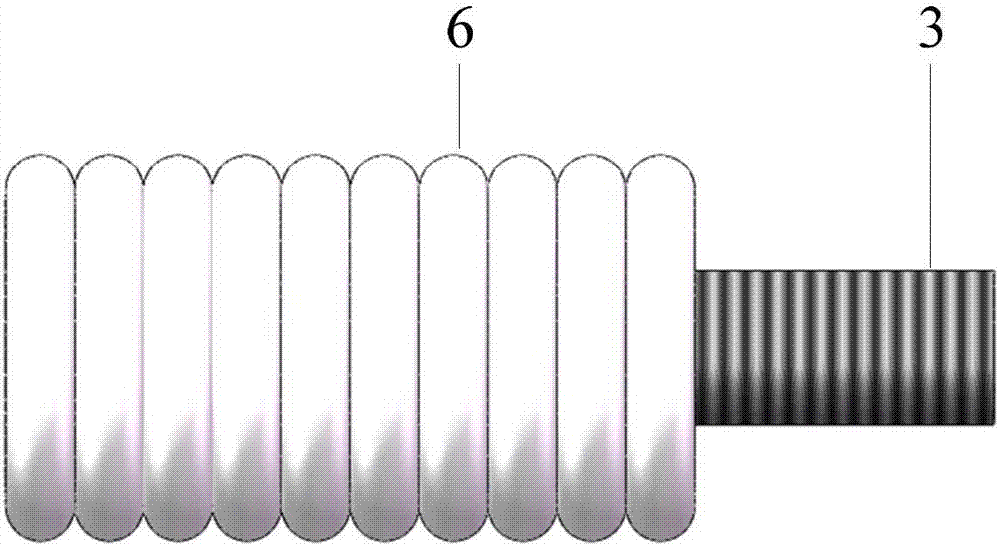

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific installation methods. The main components of the structural system include steel pipe concrete columns 1, high-strength screws 2, column end plates 3, plastic films 4, reserved screw holes 5, pre-embedded corrugated sleeves 6, threaded steel sleeves through the core 7, upper connecting screws 8, Steel anchor plate 9, lower end screw rod 10, nut 11, prefabricated reinforced concrete foundation 12, the construction sequence of structure of the present invention is as follows:

[0028] 1. In addition to the need to pour self-compacting cement base on the pre-embedded corrugated casing of the foundation on site, all components are prefabricated in the factory. For the column section size and steel pipe wall thickness, column end plate, anchor bolt number and spacing, and the configuration of the concrete foundation Steel bars shall meet the structural r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com