Steel tube derusting machine

A technology for removing rust and steel pipes, applied in the field of polishing machine tools, can solve the problems of low efficiency of rust or residual oxide layer, inability to adjust the contact friction speed between the steel wire wheel and the surface of the steel pipe, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

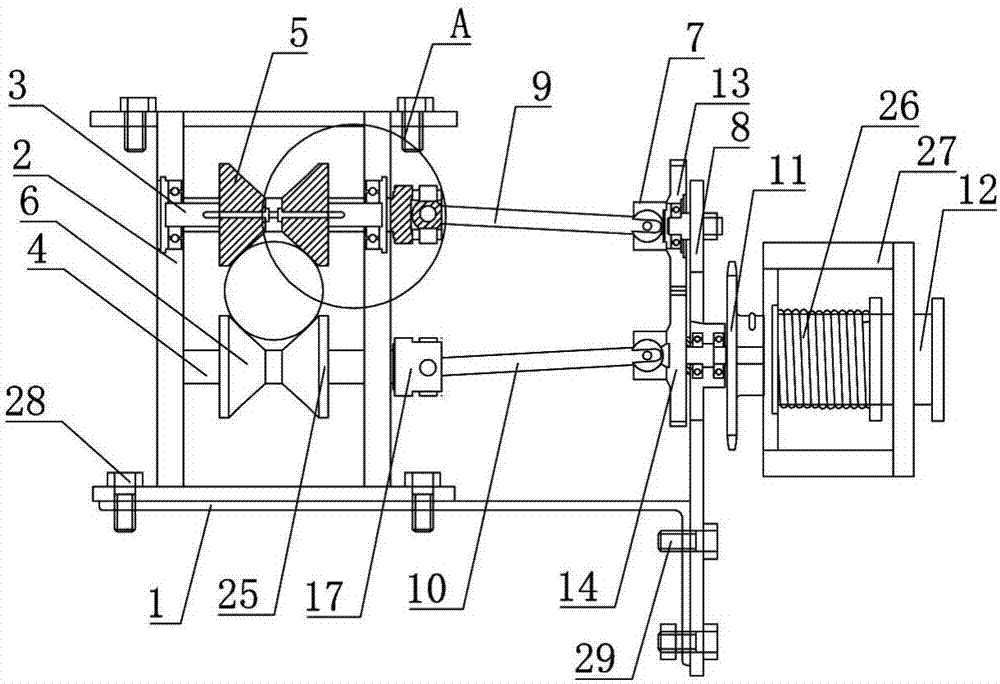

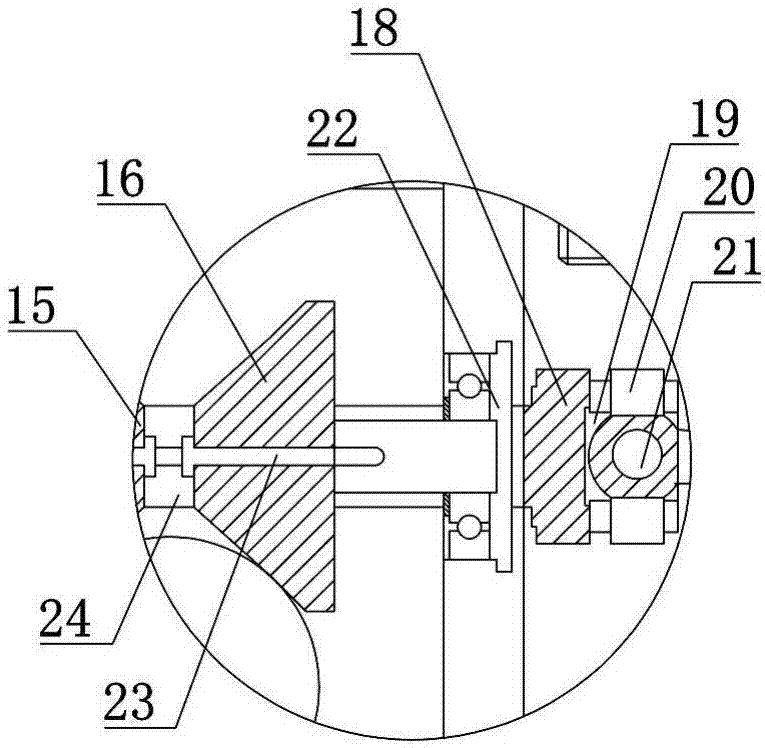

[0026] like figure 1 , figure 2 As shown, the steel pipe derusting machine includes a base 1, a door-shaped bracket 2 is fixed on the base 1, a first rotating shaft 3 and a second rotating shaft 4 are arranged on the door-shaped bracket 2, and the first rotating shaft 3 is located above the second rotating shaft 4. The first steel wire wheel 5 is overcoated on the central axis of the first rotating shaft 3, and the second steel wire wheel 6 is overcoated on the central axis of the second rotating shaft 4. The right side of the door-shaped support 2 is provided with a tensioning mechanism 7, and the tensioning mechanism 7 includes a tensioning bracket 8 , the first rocker 9 for controlling the action of the first rotating shaft 3, the second rocker 10 for controlling the action of the second rotating shaft 4, the main driving disc 11, the main driving shaft 12, the first auxiliary driving disc 13, the second Auxiliary drive disc 14, first rocker 9 is arranged on the upper lef...

Embodiment 2

[0029] like figure 1 , figure 2 As shown, the steel pipe derusting machine includes a base 1, a door-shaped bracket 2 is fixed on the base 1, a first rotating shaft 3 and a second rotating shaft 4 are arranged on the door-shaped bracket 2, and the first rotating shaft 3 is located above the second rotating shaft 4. The first steel wire wheel 5 is overcoated on the central axis of the first rotating shaft 3, and the second steel wire wheel 6 is overcoated on the central axis of the second rotating shaft 4. The right side of the door-shaped support 2 is provided with a tensioning mechanism 7, and the tensioning mechanism 7 includes a tensioning bracket 8 , the first rocker 9 for controlling the action of the first rotating shaft 3, the second rocker 10 for controlling the action of the second rotating shaft 4, the main driving disc 11, the main driving shaft 12, the first auxiliary driving disc 13, the second Auxiliary drive disc 14, first rocker 9 is arranged on the upper lef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com