Apparatus for recycling iodine from dilute phosphoric acid

A technology for recovering iodine and dilute phosphoric acid, which is applied in the direction of iodine, phosphorus compounds, iodine/hydrogen iodide, etc., and can solve problems such as clogging production pipelines and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

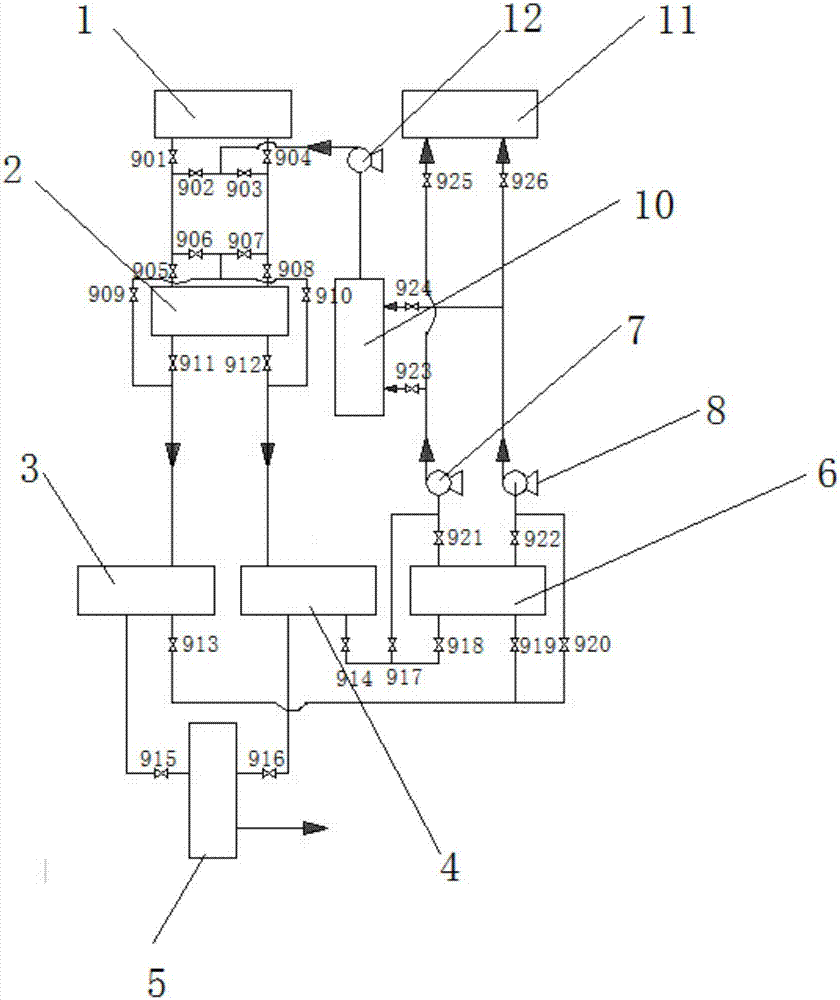

[0026] As mentioned above, when the device is in operation, the iodine-containing acid liquid discharged from the acid tank 1 enters the reactor 2 in a double-pipeline manner, and the two outlet pipes of the reactor 2 enter the separation tower A3 and the separation tower B4 respectively, and the acid is discharged from the separation tower The outlet pipe enters the phosphoric acid tank 6, and the outlet of the phosphoric acid tank 6 also uses double pipelines to drive the acid into the concentrator 11. Both the reactor 2 and the phosphoric acid tank 6 need to be equipped with corresponding bypass pipelines, connect the inlet pipe to the outlet pipe, and configure corresponding After the recovery of the valve is completed, it enters the cleaning work. The cleaning pump 12 sends the cleaning liquid from the cleaning tank 10 through the acid that is not in production state, bypasses the reactor 2 through the fourth bypass line, and enters the separation tower to be cleaned. Afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com