Preparation of multi-cavity carbon spheres by a self-assembly method driven by surface energy and its application

A self-assembly and cavity technology, applied in the preparation/purification of carbon, nano-carbon, nanotechnology, etc., can solve the problem that microfluidic technology is difficult to produce large quantities of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Weigh 100mg of surfactant F127, add it into 10ml of deionized water, stir and dissolve at 40°C for 2h. Dissolve 50 mg of stearic acid in 0.5 mL of n-hexane, pour it into an aqueous solution of surfactant, and sonicate for 30 min to obtain a translucent white emulsion. Distill under reduced pressure at 50°C for 0.5h to remove n-hexane in the emulsion to obtain solution A. Weigh 275mg resorcinol, 210mg hexamethylenetetramine, 90ml deionized water, stir well at 40°C, add solution A, stir slowly and mix well to obtain solution B. The reaction solution B was transferred to a hydrothermal kettle, and hydrothermally reacted at 110°C for 4 hours to obtain a monodisperse multi-cavity polymer colloid solution C, which was centrifuged, washed with water and ethanol, and dried to obtain a dry multi-cavity polymer.

Embodiment 2

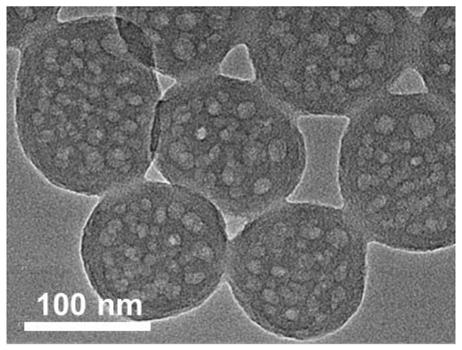

[0033] The multi-cavity polymer prepared in Example 1 was placed in a carbonization furnace for carbonization, protected by argon at 3°C / min to 150°C, kept at a constant temperature for 120min, and then raised to a carbonization temperature of 600°C at a heating rate of 5°C / min. Constant temperature for 120min, carbonization to obtain multi-cavity carbon spheres with shape retention.

[0034] The cavity size of multi-cavity carbon spheres obtained in this embodiment is 12 ± 2nm, the number of cavities is 40 ± 5, and the diameter of carbon spheres is 105 ± 10nm. The transmission electron microscope shows figure 1 shown.

Embodiment 3

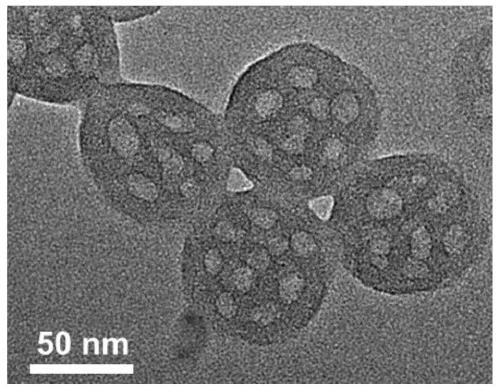

[0036]Take 50ml of solution B in Example 1, add 50ml of deionized water, mix and stir evenly, transfer the obtained solution into a hydrothermal kettle, and perform a hydrothermal reaction at 110°C for 4h to obtain a monodisperse multi-cavity polymer colloid solution. Centrifuge, wash with water and ethanol, and dry to obtain a dry multi-cavity polymer. The multi-cavity polymer prepared in this example was placed in a carbonization furnace for carbonization, and the method was the same as in Example 2 to obtain multi-cavity carbon spheres.

[0037] The cavity size of multi-cavity carbon spheres obtained in this embodiment is 12 ± 2nm, the number of cavities is 10 ± 2, and the diameter of carbon spheres is 70 ± 5nm. The transmission electron microscope shows figure 2 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com