Formula and method for commonly treating wet-method smelting slag and coal-series solid waste

A hydrometallurgy and solid waste technology, which is applied in the field of hydrometallurgy slag and coal-based solid waste treatment, can solve the problems of long treatment period and quick solution to the hazards of coal gangue accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] The ordinary wet smelting slag is dried and dehydrated at high temperature, so that the moisture content of the smelting slag is reduced from 78% to less than 10%. The fly ash itself has a moisture content of less than 5%, so it does not need to be dried, and can be directly ground and sieved for use.

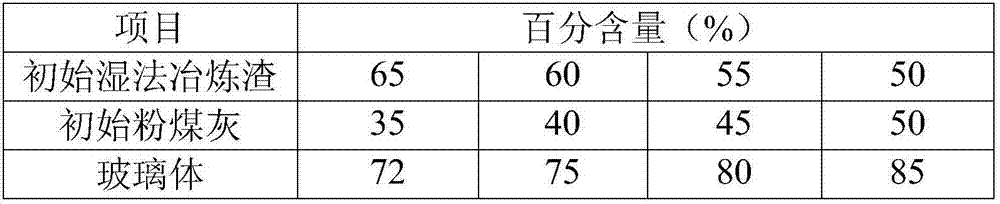

[0063] The ground and sieved wet smelting slag and fly ash are uniformly mixed in mass percentages of 65:35; 60:40; 55:45; 50:50, respectively.

[0064] The mixture was melted at a high temperature at 1400°C and kept for 2 hours.

[0065] The mass percent of vitreous body in the vitrified products of the four mixtures is all greater than 70%, and the fourth formula, that is, the hydrometallurgy slag and coal gangue are mixed at a mass percentage of 50:50, and the vitreous body content obtained by melting the mixture can reach up to 85% (detection method for XRD). The vitreous body content under each proportioning ratio is as follows Table 1. The leaching toxicity of he...

Embodiment 2

[0069] The ordinary wet smelting slag is dried and dehydrated at high temperature, so that the moisture content of the smelting slag is reduced from 78% to less than 10%. The fly ash itself has a moisture content of less than 5%, so it does not need to be dried, and can be directly ground and sieved for use.

[0070] The wet smelting slag and fly ash after grinding and sieving are mixed uniformly at a mass percentage of 50:50, and the mixture is respectively placed under the conditions of 1200°C, 1250°C, 1300°C, 1350°C, 1400°C, 1450°C, and 1500°C Melt at high temperature and keep warm for 2h.

[0071] Under the seven conditions, the vitreous body content in the vitrified product was lower than 70% at 1200°C, and the others were all higher than 70%, and as the melting temperature increased, the vitreous body content in the vitrified product increased, up to more than 85% (the detection method is XRD, the specific results are shown in Table 2). The leaching toxicity of heavy me...

Embodiment 3

[0075] The ordinary wet smelting slag is dried and dehydrated at high temperature, so that the moisture content of the smelting slag is reduced from 78% to less than 10%. The fly ash itself has a moisture content of less than 5%, so it does not need to be dried, and can be directly ground and sieved for use.

[0076] The wet smelting slag and fly ash after grinding and sieving were mixed evenly at a mass percentage of 50:50, and the mixture was melted at 1400°C, and the holding time was 1.0h, 1.5h, 2.0h, 2.5h, and 3h respectively.

[0077] Under the five conditions, the vitreous body content in the vitrified product was lower than 70% at 1.0h, and all others were higher than 70%. With the prolongation of the holding time, the vitreous body content in the vitrified product increased, up to more than 85% (the detection method was XRD , see the following table 3 for specific values). The leaching toxicity of heavy metals was determined by TCLP method, all of which were lower than...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com