Gold plating process of bottom hair tip of Tibet lamb skin quilt

A technology of bleaching wool tips, gold and sand sheepskin, which is applied in the field of fur processing, can solve the problems of single dyeing method of wool and quilt, and achieve the effect of enhancing sensory perception, expanding the scope of application, and enhancing sensory perception

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

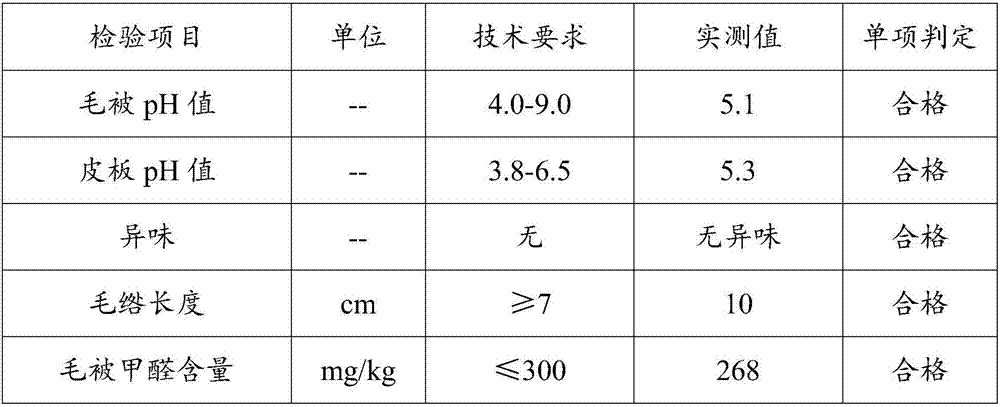

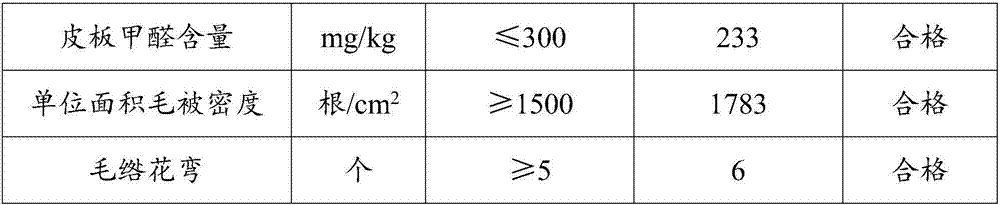

Image

Examples

Embodiment 1

[0018] The process of bleaching the bottom of the Tan sheep fur quilt and the tip of the wool, including the following steps:

[0019] 1) Degreasing: Add 30g / L salt and 2.5ml / L degreasing agent to the Tan sheepskin raw material at a temperature of 38°C to 40°C for 60 minutes, then peel, rinse, and dehydrate;

[0020] 2) Tanning: Add 30g / L salt, 1ml / L degreasing agent, 8ml / L tanning agent and 2-3g / L soda ash to the degreased Tan sheepskin at a temperature of 35°C-38°C , adjust the pH to 8.0-8.5, stay overnight, paddle intermittently for 2 hours the next day, and peel the skin;

[0021] 3) Mordant dyeing: Add 0.5ml / L degreasing agent, 15g / L ferrous sulfate, 30g / L salt, and 1ml / L acetic acid to the tanned sheepskin at a temperature of 32°C to 35°C for mordant dyeing , adjust the pH to 4.0, after 15 to 24 hours, peel the skin;

[0022] 4) Bleaching: Add 40g / L salt, 15g / L Weijia bleaching agent, 8g / L hair conditioner, 0.5ml / L Bleaching with formic acid for 15 minutes, then addin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com