Three-dimensional crimped PVA (polyvinyl acetate) fiber as well as preparation method and application thereof

A three-dimensional crimping and fiber technology, applied in the direction of fiber processing, fiber chemical characteristics, chemical instruments and methods, etc., to achieve the effects of improving stability, reducing damage, and improving the ability of temporary plugging and cementing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

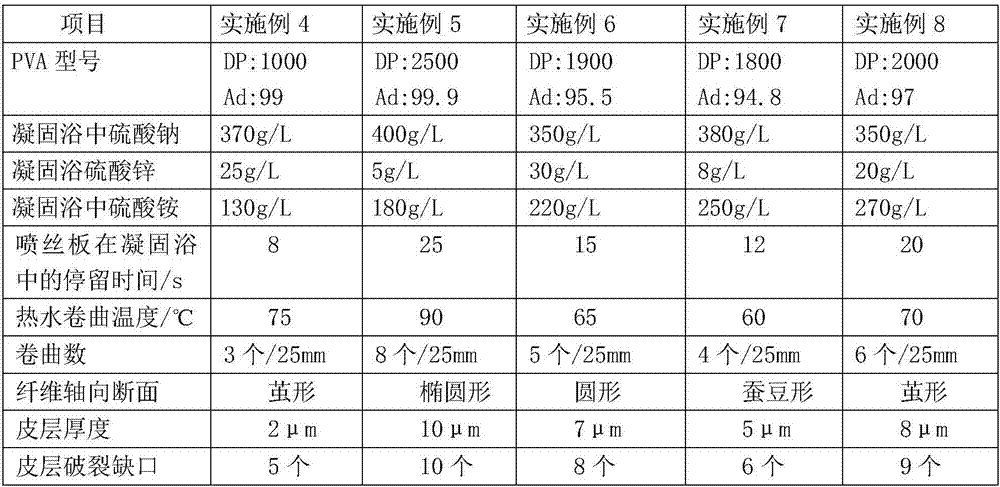

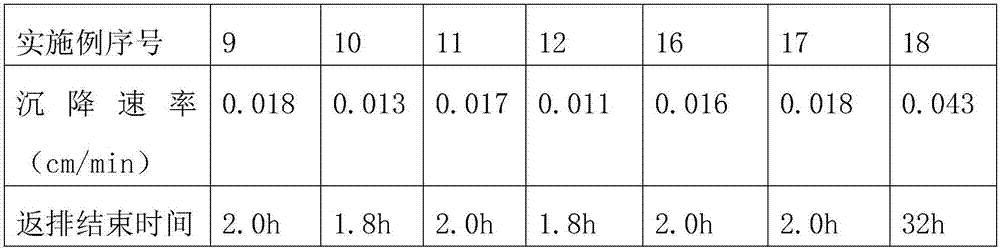

Examples

Embodiment 1

[0040] (1) Preparation of spinning dope: PVA with a degree of polymerization of 2000 and a degree of alcoholysis of 98.5 (mol)% is dissolved in water while stirring to form a spinning dope. The mass concentration of PVA in the dope is 16%. The stock solution is heated to 95°C, maintained at a pressure of 0.08MPa, and dissolved for 8 hours before entering the spinning process.

[0041] (2) Spinning: The PVA stock solution is sent to the spinning assembly by a metering pump, the PVA stock solution is spun through the spinneret, and the filaments enter the coagulation bath to form. The components of the coagulation bath are sodium sulfate, zinc sulfate, ammonium sulfate and sulfuric acid. The concentration of sodium sulfate in the coagulation bath is 370g / l, the concentration of zinc sulfate in the coagulation bath is 30g / l, and the concentration of ammonium sulfate in the coagulation bath It is 150g / l. After sulfuric acid is added, the pH of the coagulation bath is adjusted to 3.5,...

Embodiment 2

[0045] Use the following steps to prepare PVA fiber:

[0046] (1) Preparation of spinning dope: PVA with a degree of polymerization of 1500 and a degree of alcoholysis of 99 (mol)% is dissolved in water while stirring to form a spinning dope. The mass concentration of PVA in the dope is 15%. The stock solution is heated to 95°C, maintained at a pressure of 0.05 MPa, and dissolved for 10 hours before entering the spinning process.

[0047] (2) Spinning: The PVA stock solution is sent to the spinning assembly by a metering pump, the PVA stock solution is spun through the spinneret, and the filaments enter the coagulation bath to form. The components of the coagulation bath are sodium sulfate, zinc sulfate, ammonium sulfate and sulfuric acid. The concentration of sodium sulfate in the coagulation bath is 385g / l, the concentration of zinc sulfate in the coagulation bath is 20g / l, and the concentration of ammonium sulfate in the coagulation bath After sulfuric acid was added, the pH of...

Embodiment 3

[0051] Use the following steps to prepare PVA fiber:

[0052] (1) Preparation of spinning dope: PVA with a degree of polymerization of 3000 and a degree of alcoholysis of 95 (mol)% is dissolved in water while stirring to form a spinning dope. The mass concentration of PVA in the dope is 15%. The stock solution was heated to 95°C, maintained at a pressure of 0.10 MPa, and dissolved for 15 hours before entering the spinning process.

[0053] (2) Spinning: The PVA stock solution is sent to the spinning assembly by a metering pump, the PVA stock solution is spun through the spinneret, and the filaments enter the coagulation bath to form. The components of the coagulation bath are sodium sulfate, zinc sulfate, ammonium sulfate and sulfuric acid. The concentration of sodium sulfate in the coagulation bath is 390g / l, the concentration of zinc sulfate in the coagulation bath is 10g / l, and the concentration of ammonium sulfate in the coagulation bath It is 280g / l. After sulfuric acid is ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com