Anti-static crease-resistance polyester fabric and preparation method thereof

An antistatic and anti-wrinkle technology, which is applied in the field of textile fabrics, can solve the problems of inability to meet the needs of repeated use and the decline of antistatic performance, and achieve the effects of saving care time, reducing preparation costs, and excellent anti-wrinkle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The preparation method of the antistatic wrinkle-resistant polyester fabric provided by the invention is energy-saving, environment-friendly, simple and easy to operate, thereby reducing the preparation cost of the antistatic wrinkle-resistant polyester fabric.

[0044] In a preferred embodiment of the present invention, the plasma treatment includes the following steps: placing the blank under a plasma treatment gas with a pressure of 42-48 Pa, and treating it for 5-10 minutes. The plasma gas is selected from helium, nitrogen or argon.

[0045] Through plasma treatment, the surface of the woven gray fabric has better wetting performance, so as to facilitate dyeing treatment and drying and setting.

[0046] In a preferred embodiment of the present invention, the temperature for high-temperature dyeing is 125-135° C., and the time for high-temperature dyeing is 180-240 minutes.

[0047] When dyeing at high temperature, add the gray cloth into the prepared dyeing solutio...

Embodiment 1

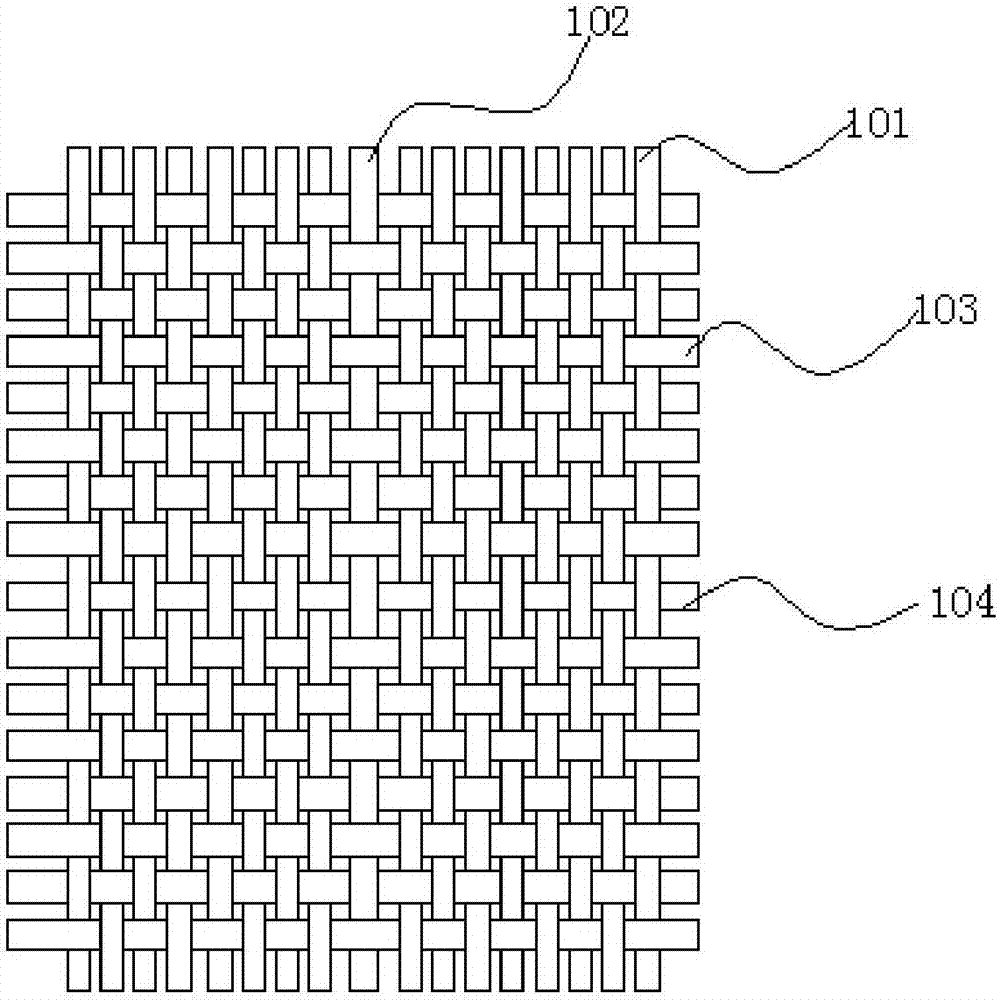

[0055] This embodiment provides an antistatic anti-wrinkle polyester fabric, which is formed by interweaving warp yarns and weft yarns, and the density in the warp direction is 55 threads / cm, and the density in the weft direction is 28 threads / cm. The warp threads include the first warp thread and the second thread. The warp yarns, the first warp yarns and the second warp yarns are arranged at intervals, and the interval ratio is 35:1; the weft yarns include the first weft yarns and the second weft yarns, the first weft yarns and the second weft yarns are arranged at intervals, and the interval ratio is 24:1; The first warp yarn is 45D / 70F polyester low elastic yarn, the second warp yarn is made of 70D / 70F second polyester low elastic yarn and 18D / 4F stainless steel fiber; the first weft yarn is 145D / 286F polyester low elastic yarn, The second weft yarn is made of 70D / 70F polyester low elastic yarn and 18D / 4F stainless steel fiber.

[0056] The preparation method of the antist...

Embodiment 2

[0066] This embodiment provides an antistatic anti-wrinkle polyester fabric. The difference between this embodiment and Embodiment 1 is that the density in the warp direction is 65 threads / cm, and the density in the weft direction is 33 threads / cm. The second warp yarn spacing setting ratio is 40:1; the first weft yarn and the second weft yarn spacing setting ratio are 28:1; the first warp yarn is 55D / 74F polyester low elastic yarn, and the second warp yarn is made of 80D / 74F polyester low elastic yarn Silk and 22D / 8F copper fiber are paralleled; the first weft yarn is 155D / 290F polyester low-elasticity yarn, and the second weft is made of 80D / 74F polyester low-elasticity yarn and 22D / 8F copper fiber.

[0067] The difference between the preparation method of the antistatic anti-wrinkle polyester fabric provided by the embodiment of the present invention and the embodiment 1 is that,

[0068] In step 1, the greige fabric is woven according to the spacing ratio of the first warp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com