Fine spinning fabric and processing method thereof

A worsted fabric and processing method technology, applied in the field of fabric processing, can solve the problems of not reaching the metric count of the finished yarn, unfavorable production and processing, short fiber length, etc., achieve strong luster, convenient operation, and mild operating conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

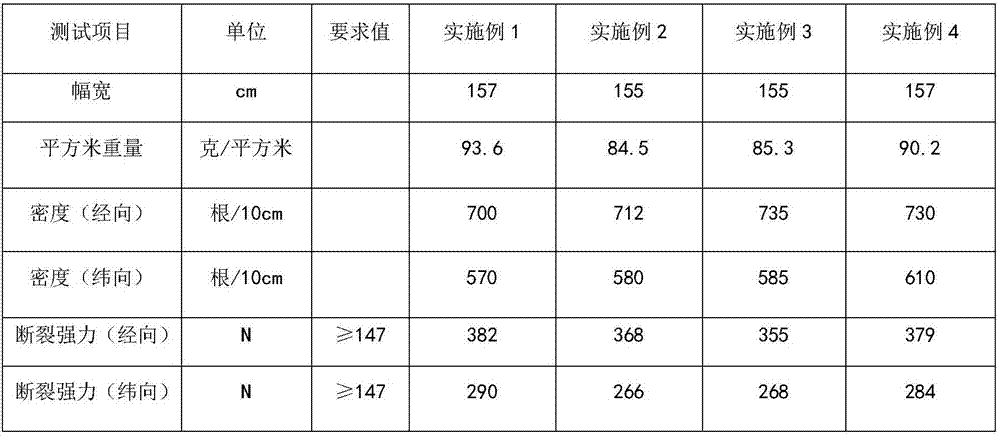

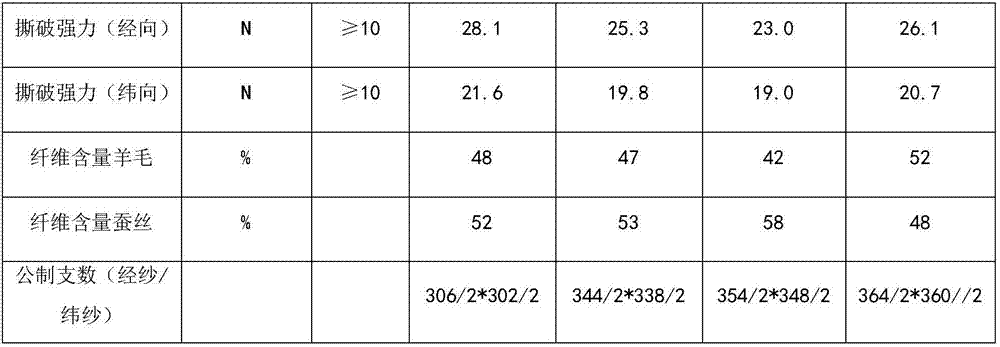

Examples

Embodiment 1

[0033] The processing process of worsted fabrics includes:

[0034] The first warp or weft selects the twist direction to be S twist, the mulberry silk fiber content is 20wt%, the water-soluble fiber content is 33wt%, and the 13μm wool content is 47wt% blended to make a 150s / 1 yarn;

[0035] Then it is spun with 20D mulberry silk filament through Sirofil spinning to make 200s / 2 wool / mulberry silk filament yarn;

[0036] The warp density of the wool worsted fabric is 700 pieces / 10cm, and the weft thread density is 570 pieces / 10cm;

[0037] The first warp and the first weft are interwoven perpendicularly to each other to form a small jacquard weave, and the weave structure makes the cloth surface have a mechanism-like appearance effect;

[0038] The fabric is soaked in water at 70°C, taken out and left to stand for 4 hours to fully swell the water-soluble fiber, and then soaked in water at 80°C for 40 minutes for de-dimensionalization to obtain a worsted fabric product.

[0039] In the wor...

Embodiment 2

[0041] The processing process of worsted fabrics includes:

[0042] The first warp or weft selects the twist direction to be S twist, the mulberry silk fiber content is 20wt%, the water-soluble fiber content is 40wt%, and the 13μm wool content is 40wt% blended to make a 150s / 1 yarn;

[0043] Then it is spun with 40D mulberry silk filament through Sirofil spinning to make 210s / 2 wool / mulberry silk filament yarn;

[0044] The warp direction density of the wool worsted fabric is 730 pieces / 10cm, and the weft direction density is 610 pieces / 10cm;

[0045] The first warp and the first weft are interwoven perpendicularly to each other to form a small jacquard weave, and the weave structure makes the cloth surface have a mechanism-like appearance effect;

[0046] The fabric is soaked in 80°C water for 20 minutes, taken out and left standing at room temperature for 5 hours to fully swell the water-soluble fiber, and then soaked in 90°C water for 60 minutes to de-dimensionalize, to obtain a wors...

Embodiment 3

[0049] The processing process of worsted fabrics includes:

[0050] The first warp or weft selects the twist direction to be S twist, the mulberry silk fiber content is 25wt%, the water-soluble fiber content is 40wt%, and the 13.5μm wool content is 35wt% blended to make a 150s / 1 yarn;

[0051] Then it is spun with 25D mulberry silk filament through Sirofil spinning to make 210s / 2 wool / mulberry silk filament yarn;

[0052] The warp density of the wool worsted fabric is 712 pieces / 10cm, and the weft thread density is 580 pieces / 10cm;

[0053] The first warp and the first weft are interwoven perpendicularly to each other to form a small jacquard weave, and the weave structure makes the cloth surface have a mechanism-like appearance effect;

[0054] The fabric is soaked in water at 75°C for 30 minutes, taken out and allowed to stand at 30°C for 5 hours to fully swell the water-soluble fiber, and then soaked in water at 85°C for 50 minutes for dedimensionalization to obtain a worsted fabric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com