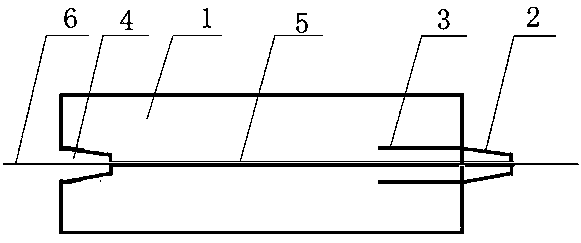

An assembled concrete road

A concrete road and concrete technology, which is applied in the field of assembling concrete roads, can solve the problems of low production efficiency, restricting the industrialization development of concrete roads, and consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] In Example 1, a sample of vanadium pentoxide, mineral admixture, and cement 2:70:500 (unit parts) was prepared. 2 parts of vanadium pentoxide, 70 parts of mineral admixtures, 500 parts of cement, 80 parts of polyethylene glycol emulsion, 1000 parts of tap water, 0.5 parts of sodium lauryl sulfate (K12) air-entraining agent, polycarboxylic acid water reducing agent 2 parts of agent and 10 parts of deionized water.

[0018] Step 1. Prepare a sealed container with a size of 1×2×2m, put 70 parts of mineral admixture (mineral powder, coal ash 1:1) into the sealed container, use a vacuum pump to vacuum to a negative pressure of 0.08MPa, and then Inject polyethylene glycol emulsion into the container, the content of polyethylene glycol emulsion is 40% (mass), and let it stand for 2 hours under stable negative pressure, and the mineral admixture (slag powder, coal ash 1: 1) Curing for 3 days at a relative humidity of 60±5% and a temperature of 25±2°C to obtain an antifreeze pretr...

Embodiment 2

[0029] In Example 2, a sample of vanadium pentoxide, mineral admixture, cement 2:70:500 (unit parts) was prepared. 5 parts of vanadium pentoxide, 80 parts of mineral admixtures, 480 parts of cement, and the amount of other raw materials. The operation steps are the same as in Example 1.

Embodiment 3

[0030] In Example 3, a sample of vanadium pentoxide, mineral admixture, and cement 2:75:500 (unit parts) was prepared. 2 parts of vanadium pentoxide, 75 parts of mineral admixture, 500 parts of cement. The amount of other raw materials is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com