Passivation emitter solar cell back silver paste

A technology for solar cells and passivated emitters, applied to conductive materials, circuits, electrical components, etc. dispersed in non-conductive inorganic materials, can solve p-n junction damage, poor adhesion between back silver and back passivation film, Problems such as poor contact performance, to achieve the effect of reducing reaction, excellent contact performance, and reducing surface recombination loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

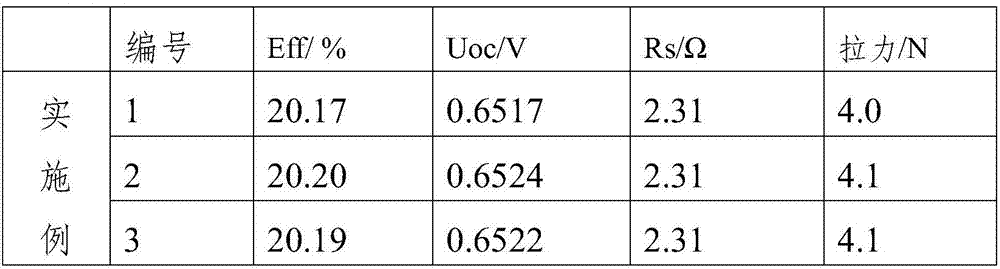

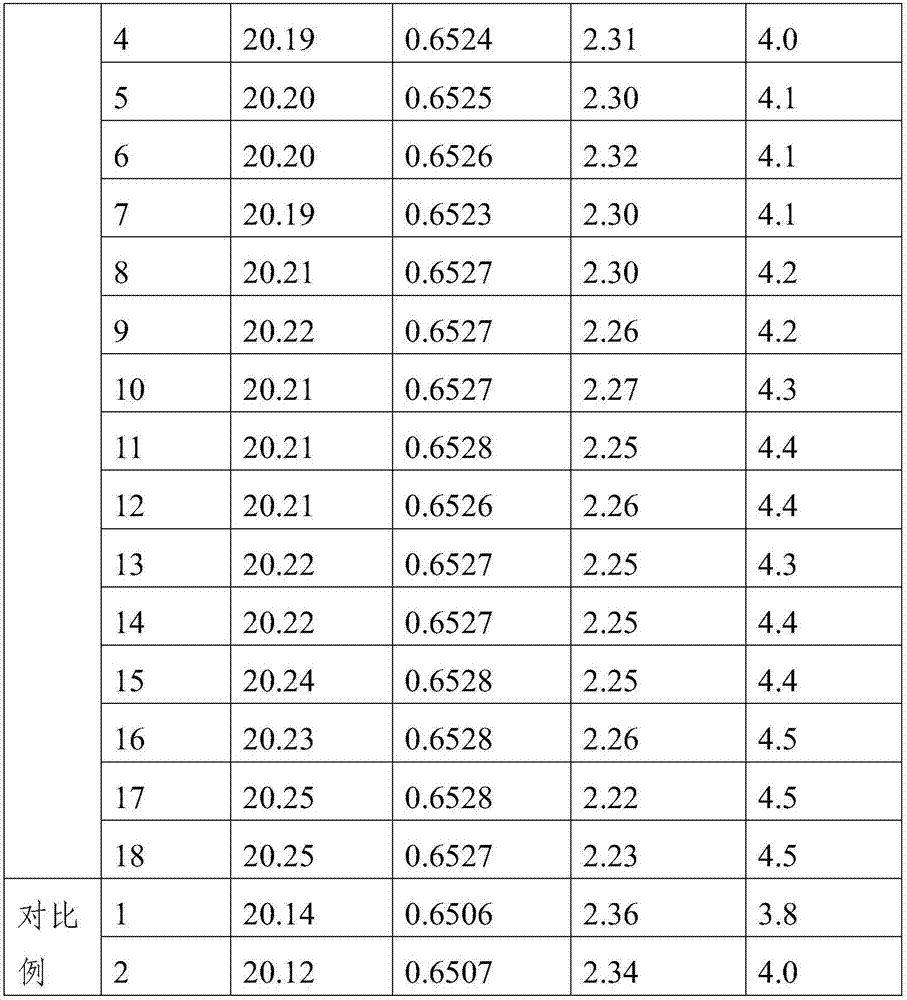

Examples

Embodiment 1

[0027] In embodiment 1, inorganic binder is PbO-ZnO-Bi 2 o 3 -B 2 o 3 -SiO 2 -Sb 2 o 3 System glass powder; wherein the organic solvent in the organic carrier is ethylene glycol butyl ether acetate, and the weight percentage of the organic solvent in the organic carrier is 80%, and the surfactant and rheological agent are not included in Example 1. The composition of glass frit A of embodiment 1 is 35% PbO, 10% Bi 2 o 3 , 5% B 2 o 3 , 40% SiO 2 , 5% Al 2 o 3 , 2% ZnO and 3% CaO; the composition of glass frit B is 30% PbO, 30% TeO 2 , 10% MnO 2 , 5% CuO and 15% ZrO 2 , the weight ratio of glass powder A to glass powder B is 10:1. The specific surface area of silver powder is 1~2m 2 / g; tap density 2.5~3.5g / cm 3 . The silver powder is selected from a conventional particle size of 0.2-1.7 μm; the thickener is alkyd resin.

Embodiment 2

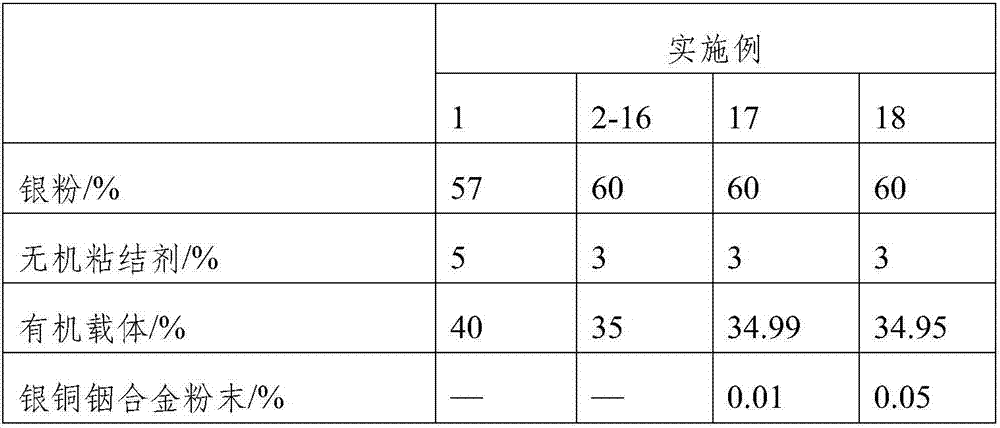

[0028] The difference between Example 2 and Example 1 lies in the weight percentage of the components of the silver paste, as shown in the above table.

[0029] The difference between embodiment 3-9 and embodiment 2 is the composition of glass powder A and glass powder B:

Embodiment 3

[0030] The composition of embodiment 3 glass powder A is: PbO20%, Bi 2 o 3 50%, B 2 o 3 5%, SiO 2 14%, Al 2 o 3 3%, ZnO6%, CaO2%; the composition of glass frit B is: PbO13%, TeO 2 20%, MnO 2 50%, CuO10%, ZrO 2 7%;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com