Two-sided adhesive membrane for lithium ion battery and lithium ion battery

A lithium-ion battery, double-sided adhesive technology, applied to secondary batteries, battery pack components, separators/films/diaphragms/spacer components, etc., can solve battery safety hazards, poor bonding effect, and easy to fall off dust and other problems, to achieve the effect of improving high-rate discharge performance, increasing customer satisfaction, and reducing dust adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

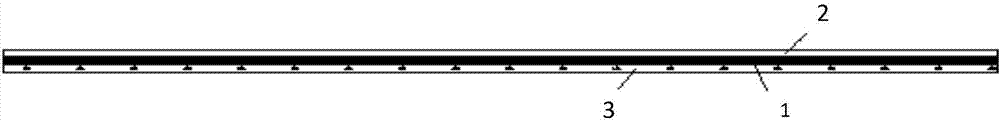

[0032] like figure 1 As shown, a double-sided adhesive separator for a lithium ion battery includes a base film 1, one side of the base film 1 is coated with a water-based PVDF adhesive layer 2 to form the A side of the separator, and the other side of the base film 1 is Coated with a polyacrylate adhesive layer 3, forming the B side of the diaphragm. The thickness of the water-based PVDF adhesive layer 2 is 0.5-2 μm, and the thickness of the polyacrylate adhesive layer 3 is 0.5-2 μm.

[0033] Wherein, the active components contained in the adhesive used in the water-based PVDF adhesive layer are PVDF, Al 2 o 3 , the PVDF and Al 2 o 3 The mass ratio is 80:20, and the solvent is water. The adhesive used in the polyacrylate adhesive layer contains an active component of 100% polyacrylate, and a solvent of water. The base film is made of PE.

Embodiment 2

[0035] On the basis of Example 1, the other side of the base film was coated with a polyacrylate adhesive layer to form the B side of the diaphragm. The thickness of the water-based PVDF adhesive layer is 1.0-3.0 μm, and the thickness of the polyacrylate adhesive layer is 1.0-3.0 μm.

[0036] Wherein, the active components contained in the adhesive used in the water-based PVDF adhesive layer are PVDF, Al 2 o 3 , the PVDF and Al 2 o 3 The mass ratio is 40:60, and the solvent is water. The adhesive used in the polyacrylate adhesive layer contains an active component of 100% polyacrylate, and a solvent of water. The base film is made of PE.

Embodiment 3

[0038] On the basis of Example 1, the other side of the base film was coated with a polyacrylate adhesive layer to form the B side of the diaphragm. The thickness of the water-based PVDF adhesive layer is 1.0-3.0 μm, and the thickness of the polyacrylate adhesive layer is 1.0-3.0 μm.

[0039] Wherein, the active components contained in the adhesive used in the water-based PVDF adhesive layer are PVDF, Al 2 o 3 , the PVDF and Al 2 o 3 The mass ratio is 50:50, and the solvent is water. The adhesive used in the polyacrylate adhesive layer contains an active component of 100% polyacrylate, and a solvent of water. The acrylate is ethyl acrylate. The base film is made of PE.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com