Special compound microorganism bacterium agent for degrading kitchen waste

A composite microbial inoculum and a technology for microbial inoculants, which are applied in the field of special composite microbial inoculants for kitchen waste degradation, can solve the problems of harsh working environment, large odor, low processing efficiency, etc., to reduce the use cost, improve the degradation efficiency, The effect of excellent deodorizing function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

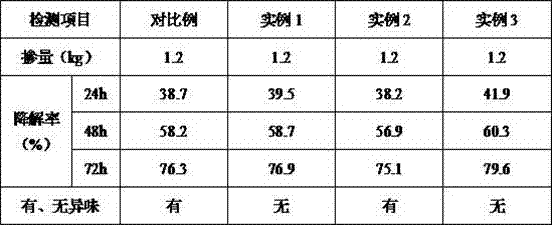

Examples

example 1

[0026] Take 600g of pig manure, 300g of chicken manure, 1kg of kaolin, and 600mL of water in turn, stir and mix for 15 minutes, and spread them evenly in a plastic water tank. 2 Add earthworms to the plastic water tank, and move the plastic water tank after adding earthworms into the greenhouse, and carry out earthworm culture at a temperature of 22°C for 15 days. During the breeding period, spray water into the water tank every 4 hours to maintain the humidity of the materials in the water tank After the vermiculture is over, collect 30g of vermicompost, and evenly spread the obtained vermicompost on the surface of the self-made solid medium, then move the self-made solid medium into the constant temperature incubator, and cultivate it at a constant temperature at 26°C After 4 days, after the cultivation was completed, the surface of the self-made solid medium was rinsed with 400 mL of deionized water, and the eluate was collected to obtain a bacterial suspension. Described s...

example 2

[0028] Weigh 900g of pine needles, wash them repeatedly 4 times with deionized water, place the cleaned pine needles in an oven, and dry them to constant weight at a temperature of 108°C, then transfer the dried pine needles to a pulverizer, and pulverize After passing through a 50-mesh sieve, the pine needle powder was obtained, and the gained pine needle powder was moved into a tubular resistance furnace, and argon gas was introduced into the furnace at a rate of 18 mL / min, and the temperature was programmed at a rate of 13 °C / min to 425°C, keep warm for 3 hours, cool to room temperature with the furnace, and discharge the material to obtain carbonized pine needle powder. Weigh 13g of ferrous sulfate, 15g of ferric sulfate, and 110g of carbonized pine needle powder in turn, and pour them into a three-necked flask filled with 450mL deionized water. , and the three-necked flask was moved into a digital display speed measuring constant temperature magnetic stirrer, at a temperat...

example 3

[0030] Weigh 900g of pine needles, wash them repeatedly 4 times with deionized water, place the cleaned pine needles in an oven, and dry them to constant weight at a temperature of 108°C, then transfer the dried pine needles to a pulverizer, and pulverize After passing through a 50-mesh sieve, the pine needle powder was obtained, and the gained pine needle powder was moved into a tubular resistance furnace, and argon gas was introduced into the furnace at a rate of 18 mL / min, and the temperature was programmed at a rate of 13 °C / min to 425°C, keep warm for 3 hours, cool to room temperature with the furnace, and discharge the material to obtain carbonized pine needle powder. Weigh 13g of ferrous sulfate, 15g of ferric sulfate, and 110g of carbonized pine needle powder in turn, and pour them into a three-necked flask filled with 450mL deionized water. , and the three-necked flask was moved into a digital display speed measuring constant temperature magnetic stirrer, at a temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com