Automobile-cantilever-beam supporting system and preparing method thereof

A cantilever beam and automobile technology, which is applied in the field of automobile cantilever beam support system and its preparation, can solve problems such as self-weight, and achieve the effects of preventing fracture risk, eliminating quality accidents, and having better mechanical properties and fatigue resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

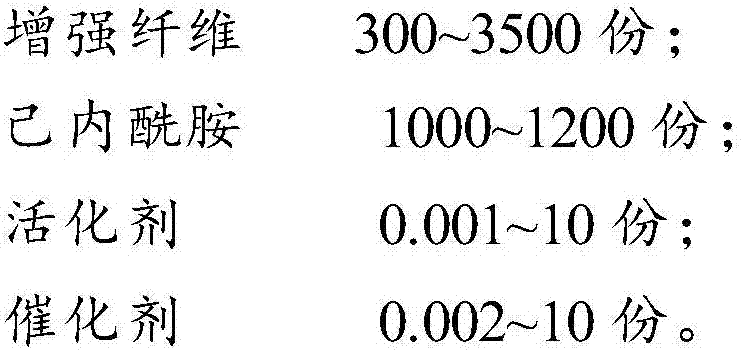

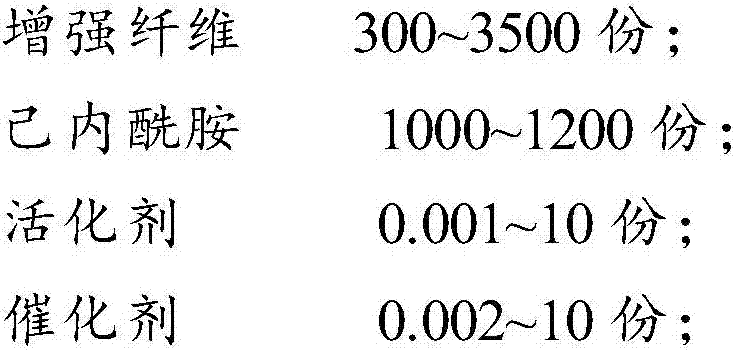

Method used

Image

Examples

Embodiment 1

[0123] 1000g of caprolactam was vacuum dehydrated at 120°C, and the mass ratio of dehydration to caprolactam was controlled to be 200ppm to obtain a dehydrated product; then 5g of HDI and 5g of sodium hydroxide were added to mix, and the temperature was raised to 150°C to obtain a melt with a viscosity of about 0.05pa.s Active material: mix and impregnate 1800g glass fiber fabric with active material at 180°C and 3MPa, then pass the glass fiber impregnated with active material through a mold with a specific cavity at a traction speed of 2m / min, extrude excess material, and mold The material inside is polymerized and solidified to obtain a glass fiber reinforced nylon composite support rod.

[0124] Insert the prepared rod into a specific mold. 1000g of caprolactam was vacuum dehydrated at 120°C, and the mass ratio of dehydration to caprolactam was controlled to be 200ppm to obtain a dehydrated product; then 5g of HDI and 5g of sodium hydroxide were added to mix, and the temper...

Embodiment 2

[0130] 1000g of caprolactam was vacuum dehydrated at 120°C, and the mass ratio of dehydration to caprolactam was controlled to be 200ppm to obtain the dehydrated product; then, 3g of MDI and 3g of sodium hydroxide were added to mix, and the temperature was raised to 150°C to obtain a melt with a viscosity of about 0.05pa.s Active material: mix and impregnate 1800g of carbon fiber fabric and active material at 120°C and 3MPa, then pass the glass fiber impregnated with active material through a mold with a specific cavity at a traction speed of 2m / min, and extrude excess material. The material is polymerized and solidified to obtain a carbon fiber reinforced nylon composite support rod.

[0131] Insert the prepared rod into a specific mold. 1000g of caprolactam was vacuum dehydrated at 120°C, and the mass ratio of dehydration to caprolactam was controlled to be 200ppm to obtain the dehydrated product; then, 3g of MDI and 3g of sodium hydroxide were added to mix, and the temperat...

Embodiment 3

[0137] 1000g of caprolactam was vacuum dehydrated at 120°C, and the mass ratio of dehydration to caprolactam was controlled to be 200ppm to obtain a dehydrated product; then, 5g of butylene diisocyanate and 5g of sodium caprolactam were added and mixed, and the temperature was raised to 150°C to obtain a viscosity of about 0.05 Pa.s molten active material; 1800g basalt fiber fabric and active material are mixed and impregnated at 180°C and 3MPa, and then the glass fiber impregnated with active material is passed through a mold with a specific cavity at a traction speed of 2m / min, extruded Excess material is discharged, and the material in the mold is polymerized and solidified to obtain a support rod of glass fiber reinforced nylon composite material.

[0138] Insert the prepared rod into a specific mold. 1000g of caprolactam was vacuum dehydrated at 120°C, and the mass ratio of dehydration to caprolactam was controlled to be 200ppm to obtain a dehydrated product; then, 5g of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com