Filtering medium for selectively filtering out leucocytes and platelets, and preparation method thereof

A filter medium and platelet technology, which is applied in the field of white blood cell filtration, can solve the problems of red blood cell adsorption and reduce electrostatic repulsion, and achieve the effect of improving interception, improving use safety, and not affecting integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

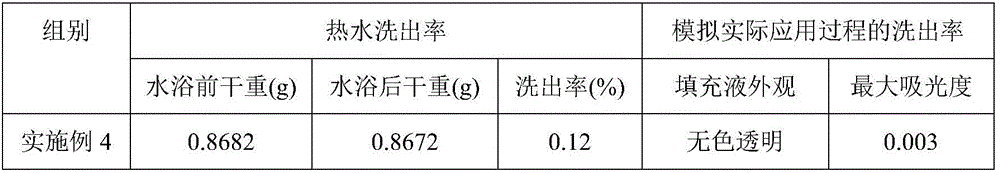

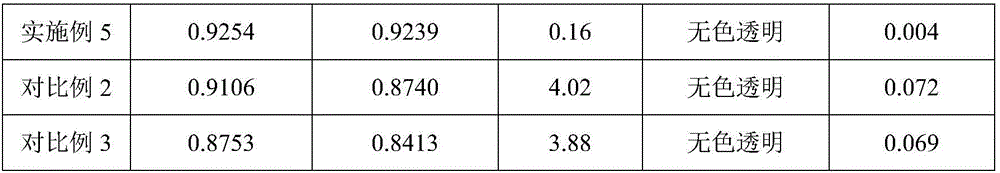

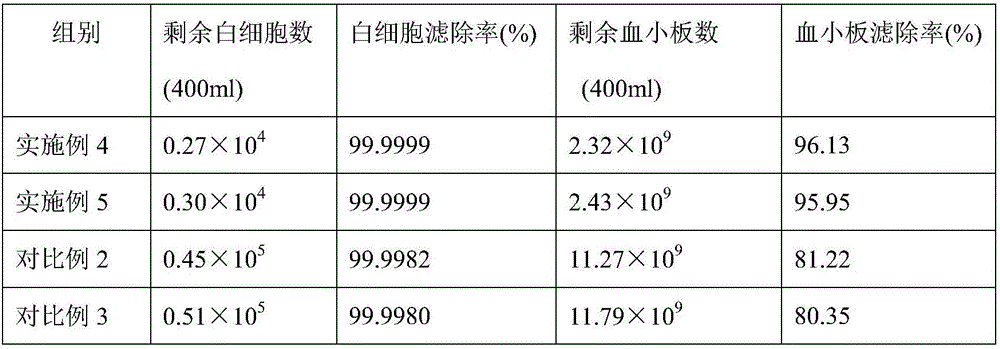

Examples

Embodiment 1

[0035] The preparation of embodiment 1 filter substrate

[0036] (1) Dissolve polysulfone in dichloromethane to make a 2% (w / v) solution, add 2% (v / v) chloromethyl ether to the system, heat and react in a water bath at 35°C for 12 hours, and after the reaction, Place the product in absolute ethanol for precipitation, wash with ethanol for several times, and then wash with deionized water for several times to ensure that the chloride ions have been completely removed, filter, and dry the product in an oven at 60°C for 24 hours. Transfer to a vacuum drying oven and dry at room temperature for 12 hours to obtain chloromethylated polysulfone;

[0037] (2) Add 1.5 times the weight of the reaction solution to the chloromethylated polysulfone, and the reaction solution is mixed with phthalimide and sodium hydride at a mass ratio of 1:0.15 to form a concentration of 4%. (w / v) aqueous solution, heated to reflux for 6 hours, cooled, precipitated the product with methanol, washed it rep...

Embodiment 2

[0039] The preparation of embodiment 2 cellulose acetate particles

[0040] Take cellulose acetate and add deionized water to make a suspension with a mass concentration of 4% (m / v), add polyamide polyamine epichlorohydrin, the cellulose acetate and polyamide polyamine epichlorohydrin The mass ratio is 1:0.3; ultrasonic treatment for 30min, then sealed in a high-pressure steam boiler, treated at 180°C for 6h, cooled to room temperature, centrifuged to collect the precipitate, washed 3 times with deionized water, and vacuum-dried at 80°C for 6h , that is, cellulose acetate particles coated with polyamide polyamine epichlorohydrin on the surface.

Embodiment 3

[0041] The preparation of embodiment 3 cellulose acetate particles

[0042] Take cellulose acetate and add deionized water to make a suspension with a mass concentration of 2% (m / v), add polyamide polyamine epichlorohydrin, the cellulose acetate and polyamide polyamine epichlorohydrin The mass ratio is 1:0.24; ultrasonic treatment for 20min, then sealed in a high-pressure steam boiler, treated at 180°C for 4h, cooled to room temperature, centrifuged to collect the precipitate, washed 3 times with deionized water, and vacuum-dried at 80°C for 6h , that is, cellulose acetate particles coated with polyamide polyamine epichlorohydrin on the surface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com