Polypropylene modified material and preparation method thereof

A modified material, polypropylene technology, applied in the field of polypropylene materials, can solve the problems of poor compatibility, low flame retardant performance, material processing performance and mechanical properties and negative effects of mechanical properties, etc., to achieve good mechanical properties, electrical insulation. Good performance and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0042] The experimental methods described in the following examples, unless otherwise specified, are conventional methods; the reagents and materials, unless otherwise specified, can be obtained from commercial sources.

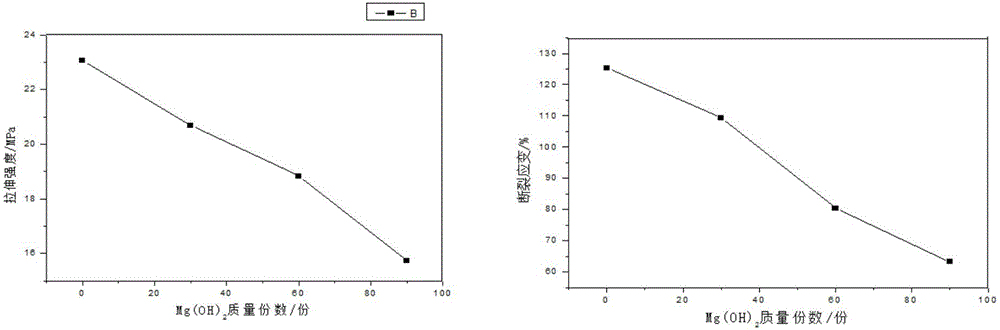

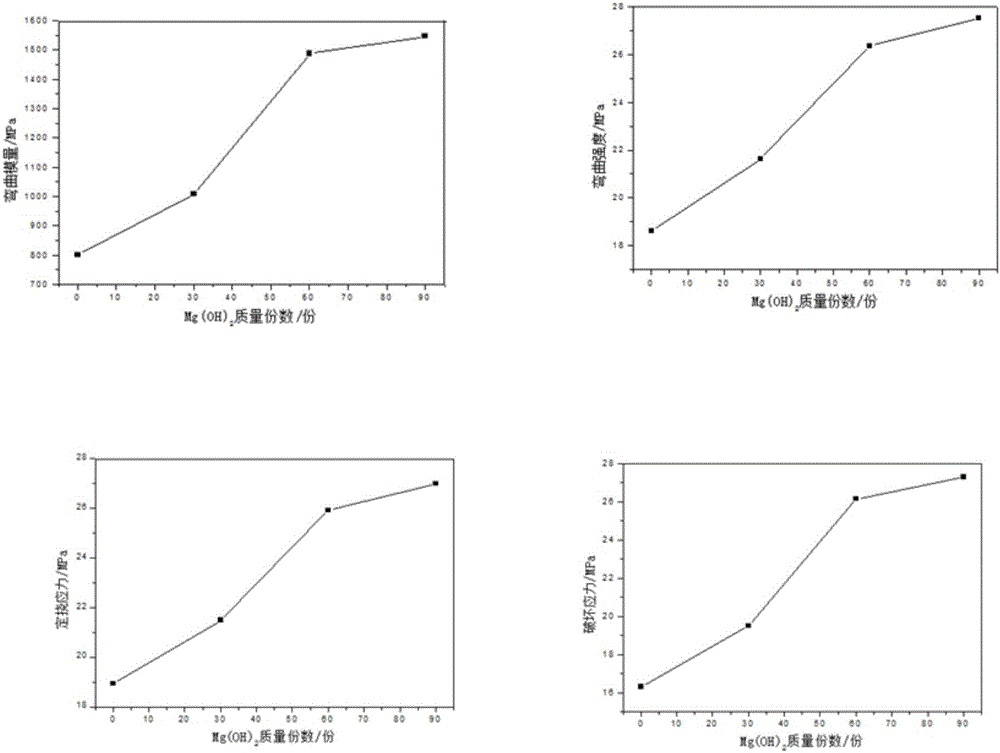

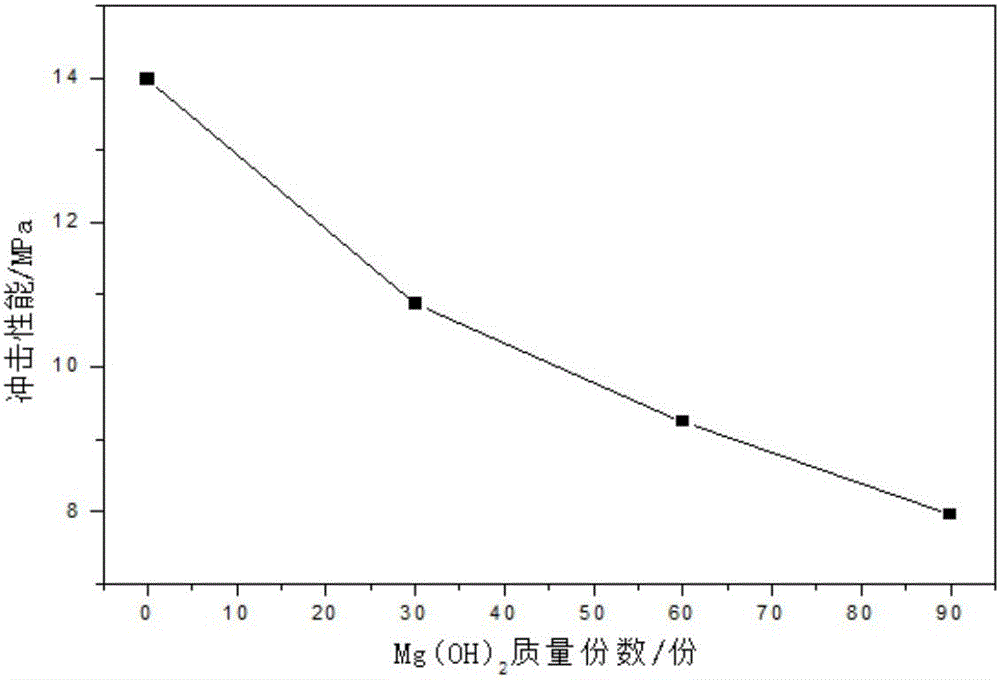

[0043] One, the sample of material described in the present invention and the preparation of comparative sample

[0044]

[0045]

[0046] Table 1

[0047] Recipe 11 Recipe 12 Recipe 13 PP 100 100 100 Mg(OH)2 60 60 60 POE 0 20 30

[0048] Table 2

[0049] The formulations in Table 1 and Table 2 are prepared in proportion, mixed evenly by a high-speed mixer, extruded by a Nanjing Jieya twin-screw extruder, cooled with water, and then granulated by a pelletizer, and the pellets are dried at 80°C After drying for 3 hours, the temperature of each section of the extruder barrel is set to 180°C, 190°C, 195°C, 200°C, 200°C, 190°C, the temperature of the head: 180°C, the melt temperature: 192°C; the frequency of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| fracture strain | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com