Micro-foaming flame-retardant polypropylene (PP) composite material and preparation method thereof

A flame-retardant polypropylene and composite material technology, applied in the field of engineering plastics, can solve the problems of the quality of polypropylene foaming materials cannot meet the requirements, the polypropylene foaming temperature range is narrow, and the foaming process is difficult to control, etc. , The effect of low equipment requirements and uniform distribution of cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

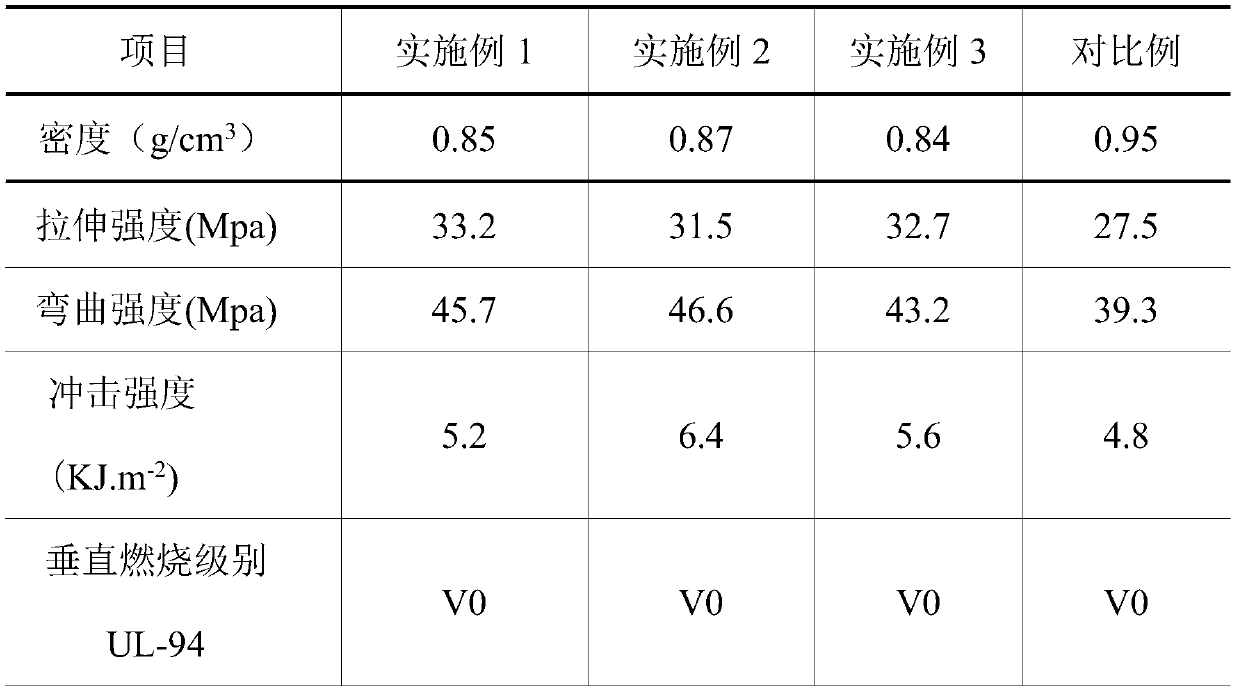

Embodiment 1

[0026] A kind of micro-foaming flame-retardant polypropylene material, its preparation raw material comprises the following components by mass percentage: polypropylene 50%, core-shell silicone rubber particles 20%, hollow glass microspheres 15%, foaming agent masterbatch 10% % and flame retardant 5%. Foaming agent masterbatch is composed of foaming agent expanded graphite, nucleating agent ultra-fine calcium carbonate, elastomer ethylene-vinyl acetate copolymer and PE resin according to the mass ratio of 10:30:20:40 through blending extrusion granulation be made of. Wherein, the extrusion temperature is 120° C., and the rotation speed of the screw of the extruder is 40 r / min. The core-shell silicone rubber particles in the preparation raw materials have a core-shell structure with silicone rubber as the core and polymethyl butyl acrylate as the shell.

[0027] The preparation method of the above-mentioned microfoaming flame-retardant polypropylene material comprises the fol...

Embodiment 2

[0031] A micro-foaming flame-retardant polypropylene material, the raw materials for its preparation include the following components in terms of mass percentage: 70% polypropylene, 10% core-shell silicone rubber particles, 10% hollow glass microspheres, and 7% foaming agent masterbatch % and flame retardant 3%. Foaming agent masterbatch is made of foaming agent expanded graphite, nucleating agent talc powder, elastomer ethylene-vinyl acetate copolymer and PE resin by blending and extrusion granulation according to the mass ratio of 15:35:15:35 . Wherein, the extrusion temperature is 130° C., and the rotation speed of the screw of the extruder is 50 r / min. The core-shell silicone rubber particles in the preparation raw materials have a core-shell structure with silicone rubber as the core and polymethyl butyl acrylate as the shell.

[0032] The preparation method of the above-mentioned microfoaming flame-retardant polypropylene material is the same as that in Example 1.

Embodiment 3

[0034] A micro-foaming flame-retardant polypropylene material, the preparation raw materials include the following components in terms of mass percentage: 65% of polypropylene, 15% of core-shell silicone rubber particles, 13% of hollow glass microspheres, and 5% of foaming agent masterbatch % and flame retardant 2%. Foaming agent masterbatch is made of foaming agent expanded graphite, nucleating agent talc powder, elastomer ethylene-vinyl acetate copolymer and PE resin by blending and extrusion granulation according to the mass ratio of 12:28:22:38 . Wherein, the extrusion temperature is 140° C., and the rotation speed of the screw of the extruder is 60 r / min. The core-shell silicone rubber particles in the preparation raw materials have a core-shell structure with silicone rubber as the core and polymethyl butyl acrylate as the shell.

[0035] The preparation method of the above-mentioned microfoaming flame-retardant polypropylene material is the same as that in Example 1. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com