Molybdenum disulfide/carbonyl iron composite microwave absorbent with core-shell structure and preparation method of molybdenum disulfide/carbonyl iron composite microwave absorbent

A microwave absorber, molybdenum disulfide technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problem of inability to achieve carbonyl iron uniform wrap absorber uniform mixing, MoS2 single shape, limit the microwave absorption performance of composite absorber and other problems, to achieve the effect of improving anti-corrosion ability, avoiding excessive agglomeration, and improving impedance matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

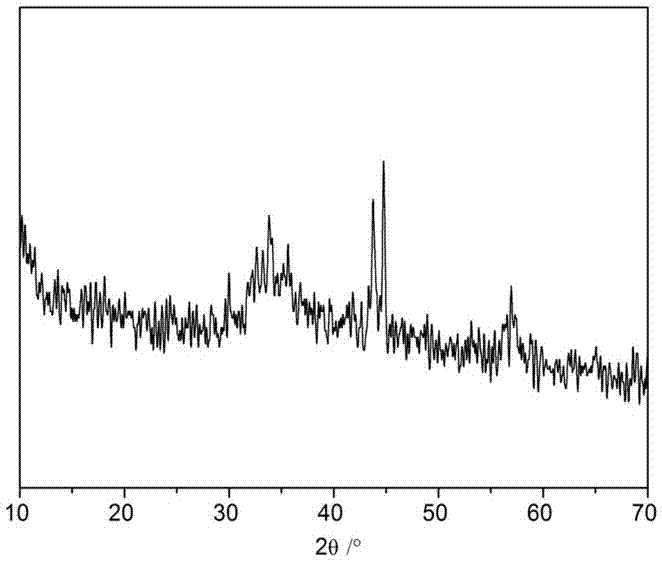

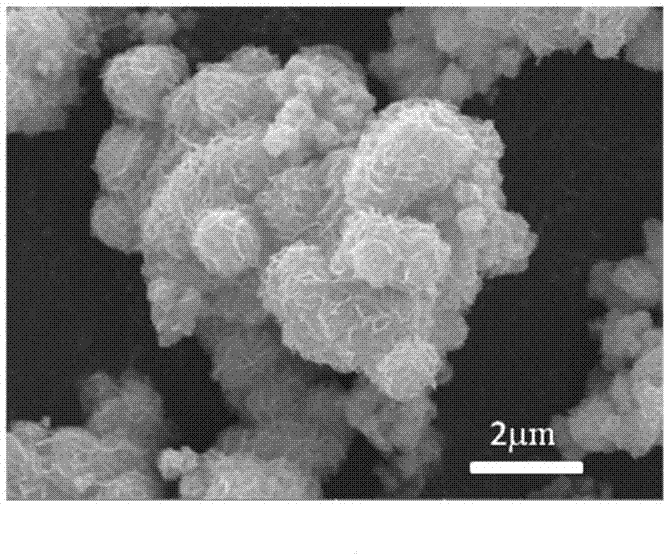

[0032] A molybdenum disulfide / carbonyl iron composite microwave absorber with a core-shell structure of the present invention, the composite microwave absorber is mainly composed of molybdenum disulfide nanopowder and carbonyl iron, the composite microwave absorber uses carbonyl iron as the core, disulfide Molybdenum nanopowder is evenly wrapped around carbonyl iron to form a core-shell structure.

[0033] A method for preparing the core-shell structure molybdenum disulfide / carbonyl iron composite microwave absorber of the above-mentioned present embodiment, comprising the following steps:

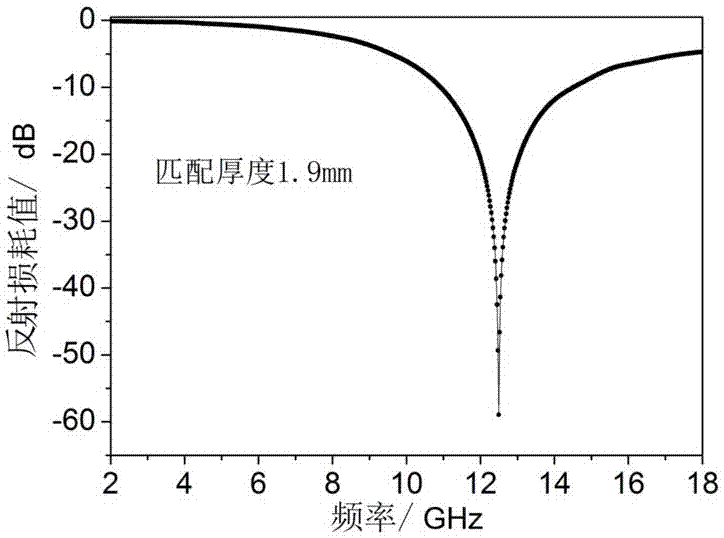

[0034] (1) Weigh 2.42g of sodium molybdate dihydrate Na with an analytical balance 2 MoO 4 2H 2 O (0.010mol), 3.0g thioacetamide CH 3 CSNH 2 (0.040mol), and the theoretically generated MoS 2 1.60 g of carbonyl iron micron powder with a mass ratio of 1:1, the particle size of the carbonyl iron micron powder is ≤10 μm, preferably ≤2 μm. First, pour the carbonyl iron micron powder into ...

Embodiment 2

[0038] A molybdenum disulfide / carbonyl iron composite microwave absorber with a core-shell structure of the present invention, the composite microwave absorber is mainly composed of molybdenum disulfide nanopowder and carbonyl iron, with carbonyl iron as the core, molybdenum disulfide nanopowder Uniformly wrapped around carbonyl iron to form a core-shell structure.

[0039] A method for preparing the core-shell structure molybdenum disulfide / carbonyl iron composite microwave absorber of the above-mentioned embodiment, the preparation steps are basically the same as in Example 1, the only difference is: step (1) theoretically generate MoS 2 The mass ratio of carbonyl iron micron powder is 1:2. Such as Figure 4 As shown, when the matching thickness of the composite microwave absorber is 2.3mm, the maximum reflection loss of the electromagnetic wave in the frequency range of 2-18GHz reaches -55.94dB, and the effective loss bandwidth reaches 2.74GHz.

Embodiment 3

[0041] A molybdenum disulfide / carbonyl iron composite microwave absorber with a core-shell structure of the present invention, the composite microwave absorber is mainly composed of molybdenum disulfide nanopowder and carbonyl iron, with carbonyl iron as the core, molybdenum disulfide nanopowder Uniformly wrapped around carbonyl iron to form a core-shell structure.

[0042] A method for preparing the molybdenum disulfide / carbonyl iron composite microwave absorber with the core-shell structure of the above-mentioned embodiment, the steps are basically the same as in Example 1, the only difference is: step (1) theoretically generate MoS 2 The mass ratio of carbonyl iron micron powder is 1:4. Such as Figure 5 As shown, when the matching thickness of the composite microwave absorber is 3.3mm, the maximum reflection loss of the electromagnetic wave in the frequency range of 2-18GHz reaches -45.86dB, and the effective loss bandwidth reaches 2.89GHz.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com