Preparation method for electronic grade tetramethylammonium hydroxide on industrial scale

A technology of tetramethyl ammonium hydroxide and tetramethyl ammonium bicarbonate, applied in electrolysis process, electrolysis components, electrolysis organic production and other directions, can solve the problems of simplicity and no description of the electrolysis process, and achieves high current efficiency and operation. Conditionally stable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

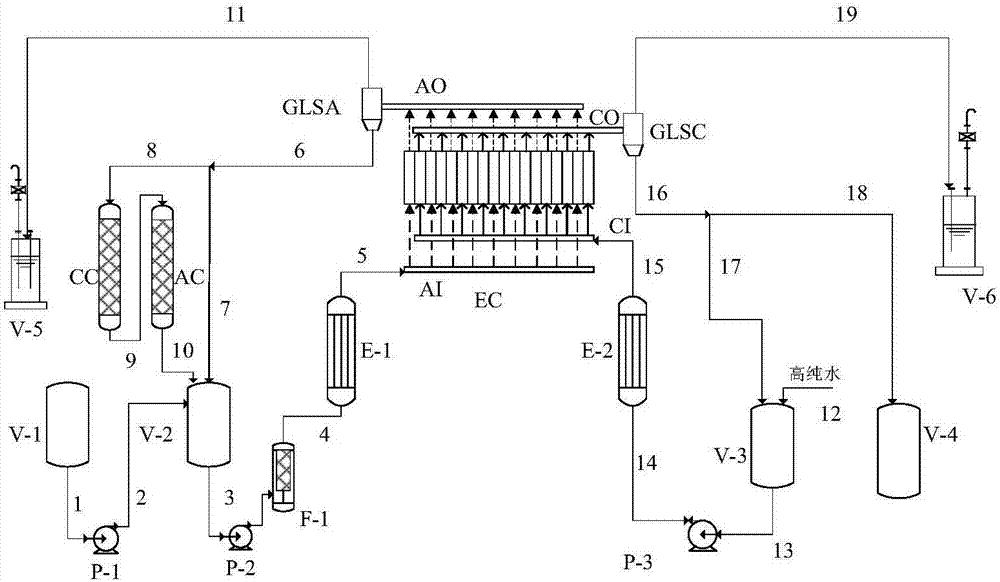

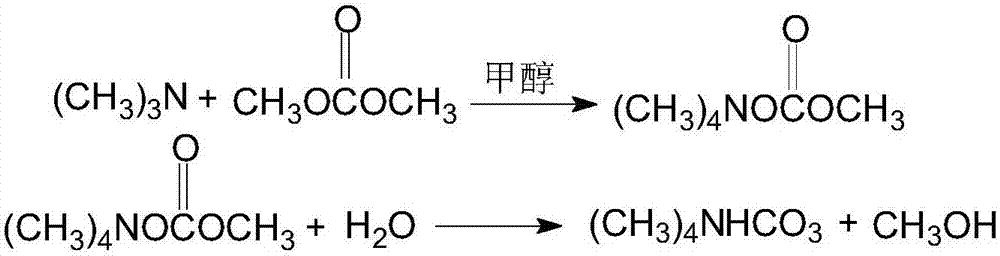

Method used

Image

Examples

Embodiment 1

[0041] Put the tetramethylammonium bicarbonate raw material with a concentration of 65.0% into the anode liquid circulation tank at a flow rate of 287.0kg / h, the concentration of the anode circulation liquid entering the electrolytic cell is 35.0%, and the flow rate of the anode circulation pump is 10.0m 3 / h, the temperature of the ion-exchange membrane electrolyzer is controlled at 50°C, the concentration of the cathodic circulating fluid is 25.8%, and the flow rate of the cathodic circulating pump is 15.0m 3 / h, the flow rate of high-purity water into the cathode circulation tank is 262kg / h, and the current density of the electrolyzer is 1.5kA / m 2 , the outlet concentration of the product TMAH is 25.8%, the flow rate is 487.8kg / h, the product is detected by ICP-MS, the content of each metal ion is less than 1ppb, and the CO in the product 3 2- and NO 3 - The content is less than 50ppb, and the product meets the quality requirements of electronic grade products.

Embodiment 2

[0043] Put the tetramethylammonium bicarbonate raw material with a concentration of 55.0% into the anode liquid circulation tank at a flow rate of 339.5kg / h, the concentration of the anode circulation liquid entering the electrolytic cell is 25.0%, and the flow rate of the anode circulation pump is 7.0m 3 / h, the temperature of the ion-exchange membrane electrolyzer is controlled at 70°C, the concentration of the cathodic circulating fluid is 26.5%, and the flow rate of the cathodic circulating pump is 9.0m 3 / h, the flow rate of high-purity water into the cathode circulation tank is 262kg / h, and the current density of the electrolyzer is 1.0kA / m 2, the outlet concentration of the product TMAH is 26.5%, the flow rate is 475.0kg / h, the product is detected by ICP-MS, the content of each metal ion is less than 1ppb, and the CO in the product 3 2- and NO 3 - The contents are 150 and 350ppb respectively, and the products do not meet the quality requirements of electronic grade p...

Embodiment 3

[0045] Put the tetramethylammonium bicarbonate raw material with a concentration of 59.3% into the anode liquid circulation tank at a flow rate of 315kg / h, the concentration of the anode circulation liquid entering the electrolytic cell is 28%, and the flow rate of the anode circulation pump is 7.0m 3 / h, the temperature of the ion-exchange membrane electrolyzer is controlled at 55°C, the concentration of the cathodic circulating fluid is 25.0%, and the flow rate of the cathodic circulating pump is 8.0m 3 / h, the flow rate of high-purity water into the cathode circulation tank is 262kg / h, and the current density of the electrolyzer is 0.8kA / m 2 , the outlet concentration of the product TMAH is 25.2%, the flow rate is 500kg / h, the product is detected by ICP-MS, and the content of each metal ion is less than 1ppb, and the CO in the product 3 2- and NO 3 - The content is less than 50ppb, and the product meets the quality requirements of electronic grade products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com