Device and method for measuring local counter electromotive force of industrial aluminum electrolytic cell

A technology of back electromotive force and measuring device, which is applied in the field of aluminum electrolysis, can solve the problems of large measurement error, difficulty in measurement, and successful measurement of signal generators, and achieve the effect of convenient operation, low cost, and solution to the setting of back electromotive force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

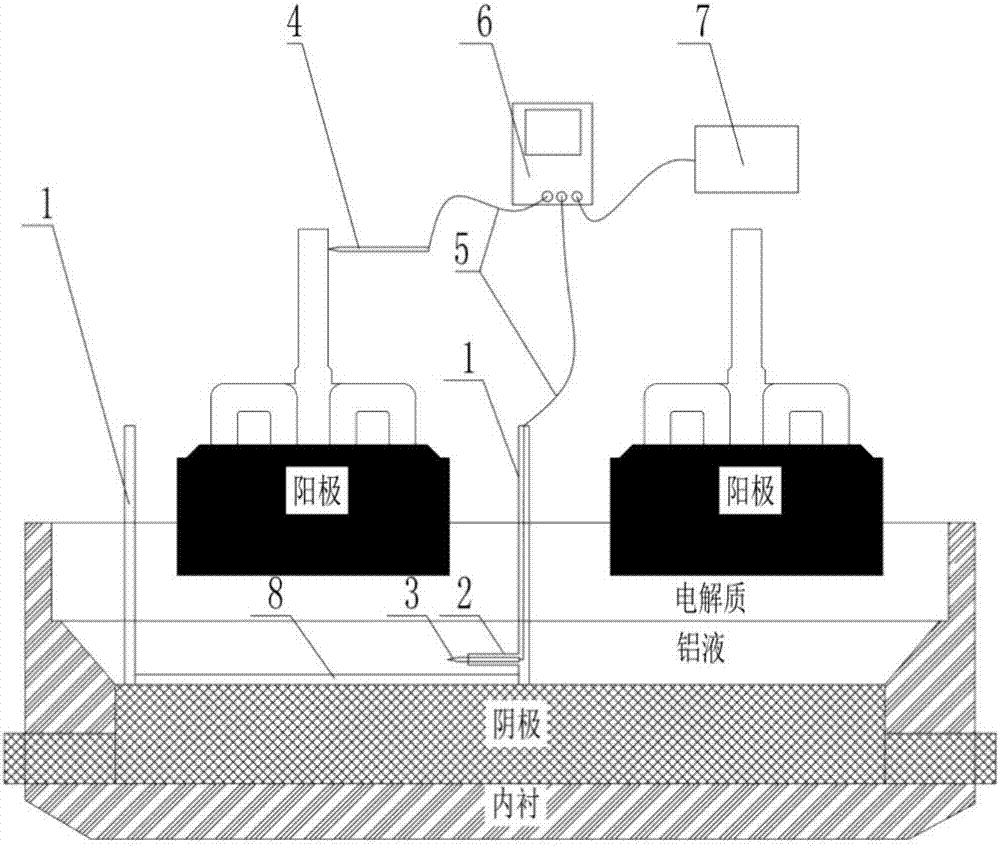

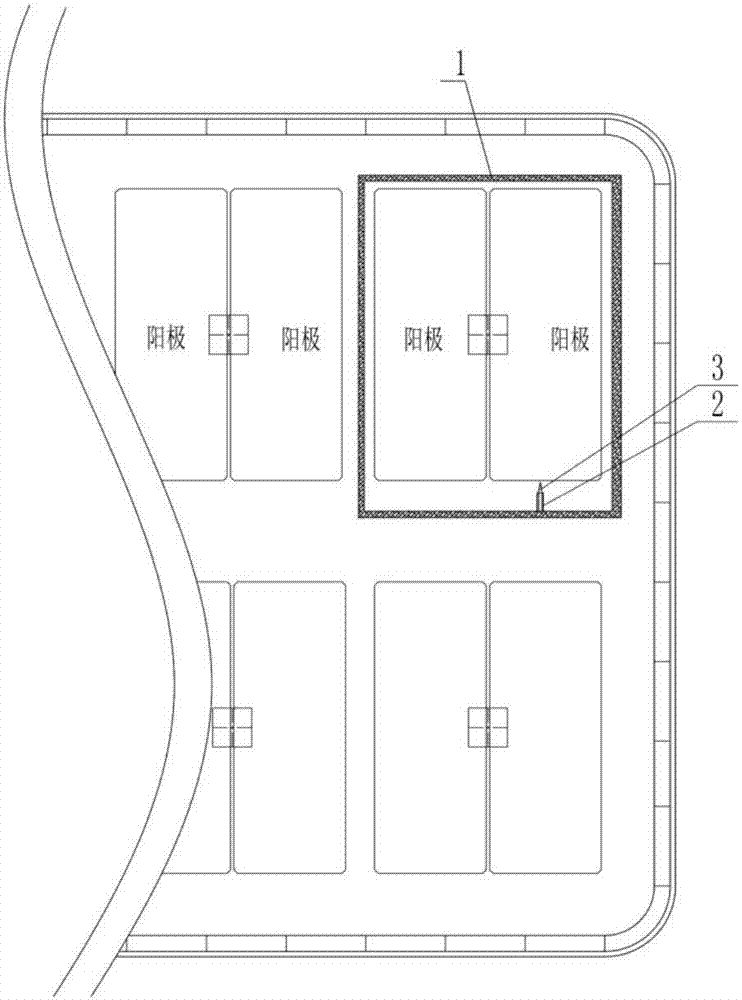

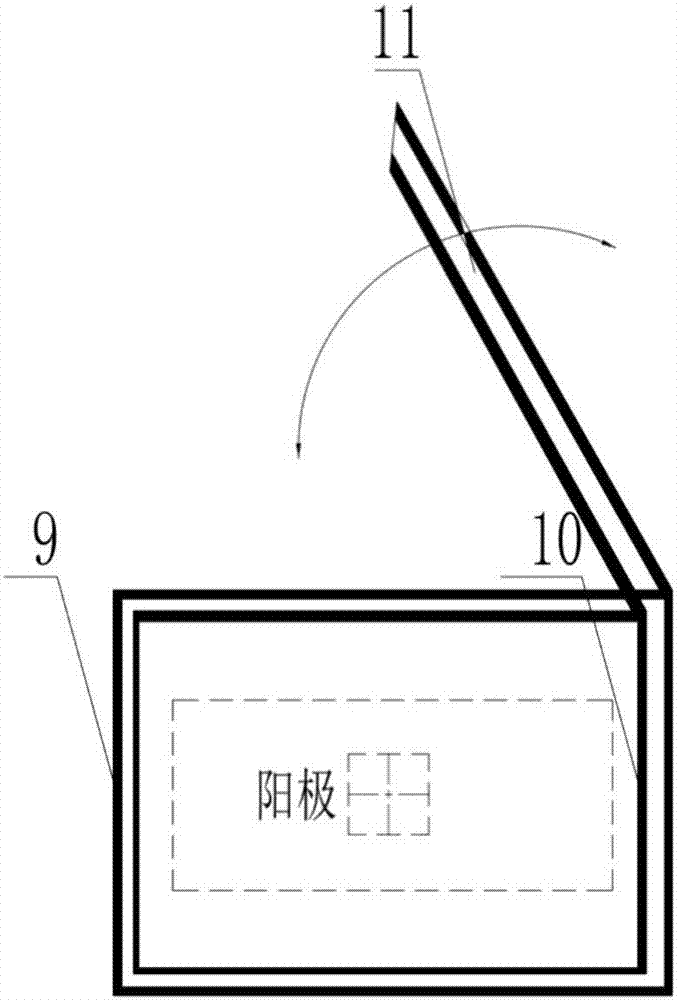

[0035]This embodiment includes a side isolation frame of the anode area, a reference electrode inside the melt, an anode guide rod voltage probe, a high temperature resistant copper wire, a high frequency digital oscilloscope, an interface module and a bottom isolation board. The side isolation frame of the anode area is composed of the outer isolation plate, the inner isolation plate and the movable isolation plate of the isolation frame, and together with the bottom isolation plate form a convenient insulating isolation frame to ensure that the measured area is powered off. The internal reference electrode of the melt is composed of an internal reference corundum tube, an external reference corundum tube, high-purity aluminum liquid, small holes in the corundum tube wall and a conductive tungsten wire, and is used to measure the current at the moment of power failure.

[0036] The material of the isolation frame 1 at the side of the anode area is high temperature resistant an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com